ASTM F111Fizzy drink container co2 volume meter Bottle temperature for cola Automatic carbonation tester for tonic water

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | 0~1MPa | Resolution | 0.1 ℃ |

|---|---|---|---|

| Shaking Speed | Adjustable | Piercing Speed | 5mm/s (other Available) |

| Sample Height | ≤ 350mm (other Available) | Temp. Range | 0 ~ 30 ℃ |

| Shaking Time | 40s (other Available) |

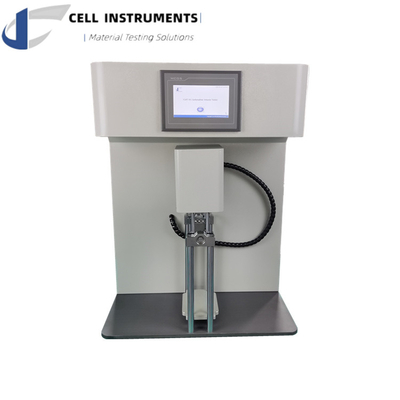

Introduction of CLRT-01 CO2 Volume Tester

![]()

The CLRT-01 Carbon Dioxide Volume Tester is an innovative solution designed by Cell Instruments, dedicated to assessing the CO2 volume in beverages. In response to the beverage industry's demand for precision and efficiency, this tester offers an automated method to establish the correlation between pressure and temperature, a vital parameter in beverage quality analysis.

Advantages of CLRT-01 CO2 Volume Tester

![]()

The CLRT-01 CO2 Volume Tester presents several advantages that set it apart in the market:

- Automation: Replacing traditional manual procedures, the tester automates the entire testing sequence, enhancing efficiency and reducing the likelihood of errors.

- Precision Control: Under precise PLC control at an industrial-grade stability level, the tester ensures accuracy in both pressure and temperature measurements, contributing to reliable test outcomes.

- Versatility: Designed to accommodate both bottles and cans, the tester offers a versatile solution for carbonation volume assessment.

- Customization: Users have the flexibility to customize shaking parameters, including frequency and duration, tailoring the testing process to specific requirements.

- Real-time Monitoring: The inclusion of high-precision pressure and temperature sensors enables real-time monitoring, ensuring the accuracy of results.

Why do you need CLRT-01 CO2 Volume Tester?

![]()

The CLRT-01 CO2 Volume Tester is a crucial tool for industries involved in beverage production. Here's why you need it:

- Quality Assurance: By automating the assessment of CO2 volume, the tester ensures consistent and high-quality carbonation levels in beverages, contributing to overall product excellence.

- Efficiency: The automated testing sequence streamlines the process, saving time and reducing the dependency on manual labor, ultimately leading to increased efficiency in production.

- Customization: The ability to customize shaking parameters allows manufacturers to adapt the testing process to meet specific product formulations and quality standards.

- Compliance: The CLRT-01 adheres to major standards such as ASTM F1115 and GB T10792, ensuring that your testing processes align with industry-accepted benchmarks.

What is the purpose of the CLRT-01 CO2 Volume Tester?

![]()

The primary purpose of the CLRT-01 CO2 Volume Tester is to provide an advanced and automated method for assessing the carbon dioxide volume in beverages. It addresses the critical need for precision in carbonation level evaluation, influencing the effervescence and sensory experience of beverages. By establishing the correlation between pressure and temperature, the tester ensures comprehensive and reliable results, empowering manufacturers to maintain product consistency and meet consumer expectations.

Application

![]()

The CLRT-01 Carbon Dioxide Volume Tester finds its application in the beverage industry, where carbonation levels play a pivotal role in determining the quality of drinks.

Technical Features:

![]()

- PLC Control: The unit operates under precise PLC control at an industrial-grade stability level, ensuring reliability and accuracy.

- Agitation Mechanism: Sample bottle agitation is achieved using a servo motor and gearbox transmission mechanism, contributing to consistent and controlled shaking.

- Anti-leak Design: The tester incorporates anti-leak features, ensuring the integrity of the testing process and preventing potential errors.

- Automated Process: The testing process involves automated piercing and shaking, streamlining the sequence for efficiency and accuracy.

- Controlled Displacement and Speed: During piercing, displacement and speed are meticulously controlled, contributing to the overall accuracy of the testing process.

- Customizable Shaking Parameters: Users have the flexibility to customize shaking parameters, including frequency and duration, to meet specific testing requirements.

- High-precision Sensors: The inclusion of a high-precision pressure sensor ensures accurate test results, contributing to the reliability of the testing process.

- Real-time Temperature Display: A high-precision temperature sensor enables real-time temperature display, further enhancing the accuracy of test outcomes.

- Automatic Presentation of Results: Post-test, the carbonation volume is automatically presented, simplifying the interpretation of results.

- Versatility: Designed to prevent leaks, this versatile tester is suitable for both bottles and cans, providing flexibility in testing different beverage packaging formats.

- Optional Features: The CLRT-01 CO2 Volume Tester offers optional features, including the incorporation of a microprinter for additional functionality and an RS 232 port with professional software for enhanced versatility.

Main Parameter

| Test Range | 0~1MPa |

| Resolution | 0.01KPa |

| Shaking Speed | Adjustable |

| Piercing Speed | 5mm/s (other available) |

| Sample Height | ≤ 350mm (other available) |

| Temp. range | 0 ~ 30 ℃ |

| Shaking time | 40s (other available) |

| Resolution | 0.1 ℃ |

Major Standards

![]()

The CLRT-01 CO2 Volume Tester complies with major industry standards, including ASTM F1115 and GB T10792. This ensures that the testing processes align with accepted benchmarks, providing confidence in the reliability and accuracy of the results.

Technical Feature

![]()

- PLC Control: Operated under precise PLC control for industrial-grade stability.

- HMI Touch Screen Interface: User-friendly interface for seamless operation.

- Servo Motor and Gearbox Transmission Mechanism: Ensures controlled and consistent sample bottle agitation.

- Anti-leak Features: Designed to prevent leaks, ensuring the integrity of the testing process.

- High-precision Sensors: Includes high-precision pressure and temperature sensors for accurate measurements.

- Automated Piercing and Shaking: Streamlines the testing process for efficiency and accuracy.

- Customizable Parameters: Allows users to customize shaking parameters to meet specific testing requirements.

- Versatility: Suitable for both bottles and cans, providing flexibility in testing different packaging formats.

- Optional Features: Optional microprinter and RS 232 port with professional software for enhanced functionality and versatility

The CLRT-01 CO2 Volume Tester from Cell Instruments stands as a cutting-edge solution in the field of beverage quality analysis. Its automated processes, precision control, and versatility make it an indispensable tool for producers seeking to ensure consistency, adapt formulations, and deliver beverages that meet the highest standards of quality and consumer satisfaction.