Medical Device Leak Testing Machine ASTM F2338 Nondestructive Detection Of Leaks In Packages By Vacuum Decay Method

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | 1Pa | Sensitivity | 1~3μm |

|---|---|---|---|

| Chamber Size | Made-On-Demand | Vacuum Pump | To Be Prepared By User |

| Power Supply | AC 110~220V 50Hz |

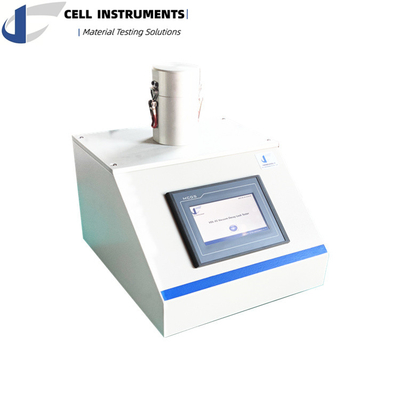

Introduction of MLT-01 Micro Leak Tester

![]()

Unlock advanced packaging integrity with the MLT-01 Micro Leak Tester, crafted by Cell Instruments for unparalleled nondestructive testing. Merging innovation with precision, this Micro Leak Tester employs the esteemed Vacuum Decay Method – a benchmark in detecting even the slightest discrepancies in package sealing.

Meeting Diverse Industry Standards

The MLT-01 Micro Leak Tester is meticulously designed to cater to a spectrum of sectors. Confirm package robustness in industries as varied as plastics, paper, textile, and beyond with this versatile instrument. The pharmaceutical, food, and beverage markets, in particular, benefit from its unwavering accuracy, safeguarding consumer health and ensuring regulatory compliance.

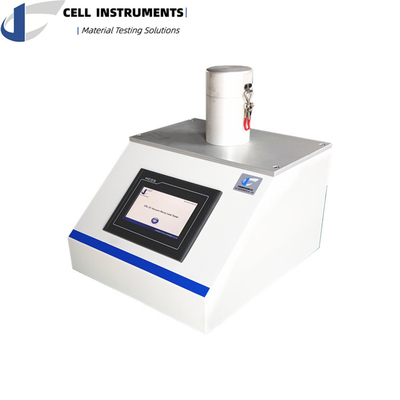

Technical Features of MLT-01 Micro Leak Tester

![]()

Operated through a PLC system and an intuitive HMI (human-machine interface), the MLT-01 boasts several technical features that make it a standout product in the field of packaging testing:

- Custom Chamber Adaptability: Our MLT-01 is adaptable with bespoke chamber sizes to accommodate a multitude of packaging formats.

- Unmatched Sensitivity: Detect the tiniest of leaks, as minimal as 1-3μm, with this incredibly sensitive Micro Leak Tester.

- Accurate Leak Quantification: Experience confidence in quality control with precise leak rate assessments ensuring your packaging's integrity.

- Streamlined Interface: Operate with ease using the MLT-01's user-oriented design, making sophisticated testing uncomplicated.

Why do you need MLT-01 Micro Leak Tester?

![]()

Quality maintenance in packaging demands an exacting eye for detail – a role epitomized by the MLT-01 as it undertakes rigorous in-depth package evaluations through its FILL, SETTLE, TEST, and VENT phases, embodying the epitome of packaging examination fidelity.

What is the purpose of the MLT-01 Micro Leak Tester?

![]()

The primary purpose of the MLT-01 Micro Leak Tester is to provide a reliable and efficient means of detecting leaks in nonporous, rigid, or flexible packages. Whether in the research phase, manufacturing, or quality control, this instrument ensures that packages meet stringent standards, preventing potential issues such as product contamination, spoilage, or compromised safety.

- Invaluable For Quality Assurance:As an integral tool in quality assurance, the MLT-01 Micro Leak Tester offers a non-invasive approach to maintaining sanitation and protecting from contaminants. This ensures that the seal of your packaging is more than a closure – it is a brand promise of safety and quality.

- Pioneer in Fostering Research and Innovation:The MLT-01 Micro Leak Tester is not only an asset to the factory floor but also the scientific community where rigorous research necessitates impeccable standards. Educational institutions and regulatory labs utilize this tester to sculpt the frontier of packaging excellence.

- Dedication to Compliance and Standards:Our MLT-01 soars beyond the industry's defined horizons. It reliably aligns with ASTM F2338 standards, symbolizing a steadfast commitment to quality that you and your stakeholders can trust implicitly.

Application

![]()

The MLT-01 Micro Leak Tester finds extensive application across various industries, including but not limited to:

- Plastics: Ensuring the integrity of plastic packaging for a wide range of products.

- Paper: Testing paper-based packaging materials to prevent leaks and maintain product quality.

- Textile: Verifying the reliability of packaging in the textile industry.

- Food: Crucial for detecting leaks in food packaging to prevent spoilage and contamination.

- Pharmaceutical: Maintaining the integrity of pharmaceutical packaging for product safety.

- Toiletry: Ensuring leak-free packaging for toiletry and personal care products.

- Printing and Adhesives: Testing packaging materials used in printing and adhesive applications for leak prevention.

Main Parameter

![]()

| MLT-01 | |

| Test Range | 1Pa |

| Sensitivity | 1~3μm |

| Chamber size | Made-On-Demand |

| Vacuum pump | to be prepared by user |

| Power Supply | AC 110~220V 50Hz |

Standards

![]()

The MLT-01 Micro Leak Tester complies with industry standards, including ASTM F2338, ensuring that it meets or exceeds the established criteria for effective packaging testing. This commitment to standards underscores its reliability and suitability for a wide range of applications in research facilities, educational institutions, and official laboratories.