Hot seal strength tester Hot tack tester ASTM F1921

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Power | Electronic | Usage | Plastic Testing Machine |

|---|---|---|---|

| Temp Accuracy | ±0.2℃ | Dwell Time | 0.1~9999s(Hot Tack) |

| Sealing Pressure | 0.15MPa~0.7MPa | Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating | Load Cell | 200N(Optional:30N50N100N, Etc) |

| Accuracy | 0.5 F.S. |

Application

The Hot Tack Tester, also known as the HTT-01 Hot Tack and Tensile Tester, is an indispensable tool for evaluating the hot seal strength of packaging materials, particularly crucial in vertical form-fill-seal (VFFS) operations. By assessing the seal strength immediately after sealing and before cooling, this tester ensures the integrity and reliability of seals in various applications. Additionally, it functions as a horizontal tensile and peeling force tester for thermoplastic surfaces, providing comprehensive testing capabilities for packaging materials across industries such as packaging, food, pharmaceuticals, and beverages.

![]()

Significance

In VFFS processes, where cooling time is limited and packages often bear substantial weight immediately after sealing, a strong hot tack force is essential to prevent seal failure and potential product spills. The Hot Tack Tester plays a vital role in maintaining seal integrity, thus safeguarding against package failures and ensuring product quality.

Standards

The Hot Tack Tester complies with industry standards such as ASTM F1921 and ASTM F2029, which outline the methodologies for evaluating hot seal strength and heatsealability of flexible webs, respectively. Adhering to these standards ensures accurate and reliable testing results, bolstering confidence in the integrity of packaging seals.

Principle

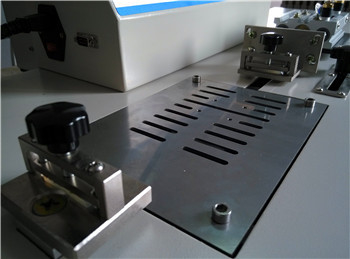

The testing process involves sealing a sample strip between two flat heated jaws under controlled parameters, including temperature, contact time, cooling time, and pressure. After a specified cooling period, the sealed area is subjected to separation at a designated speed, with the force required for separation representing the hot tack force.

Technical Features

PLC controlled operation with an intuitive HMI touch screen interface ensures industrial-level stability and user-friendly operation.

Versatile functionality allows the tester to perform hot tack, tensile, and peeling tests, offering comprehensive testing capabilities.

Integrated testing capabilities combine hot tack, peeling, and tensile tests into a single instrument, enhancing efficiency and convenience.

Precise temperature control facilitated by Delta P.I.D. temperature controller and PT100 temperature sensor ensures consistent and accurate heating.

Aluminum encapsulated sealing jaws provide uniform heating for reliable test results.

Adjustable testing speeds ranging from 1 to 2000 mm/min accommodate various testing requirements.

Safety features including auto zeroing, overload protection, and over-travel protection ensure safe and reliable operation.

Optional RS 232 port and professional software facilitate advanced data handling for comprehensive analysis and reporting.

![]()

| HTT-01 Hot Tack Tester | |

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

![]()

![]()

Cell Instruments is committed to development of material testing instruments for plastic, paper, bottle, box, containers, etc., PLC program and machinery customization. Please contact +86 531 88977152 (mail: info#celtec.cn Skype: smrelin ) for more information. Let us be a cell of your quality.