TAPPI T830 Fabric Textile Abrasion Resistance Ink Rub Tester For Ink Stability Testing About Smearing And Bleeding

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Weights | 908g (2lb) /8.9N;1816g(4lb) /17.8N | Speed | 20~120 Cpm Free Setting |

|---|---|---|---|

| Number Of Specimens | 1~2 | Rotation Radius | 185 Mm |

| Arc Length | 57 Mm ± 1 Mm | Dimension | 390x480x220 Mm (LWH) |

| Power | 110~220V 50/60Hz |

APPI T830 Fabric Textile Abrasion Resistance Ink Rub Tester For Ink Stability Testing About Smearing And Bleeding

Product Description of Ink Rub Tester

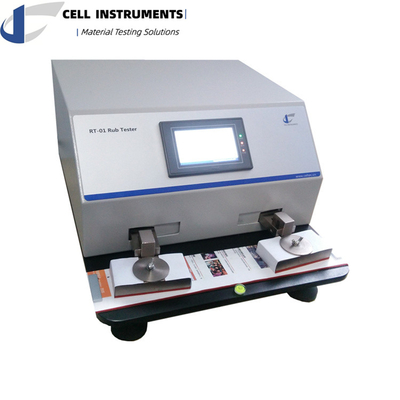

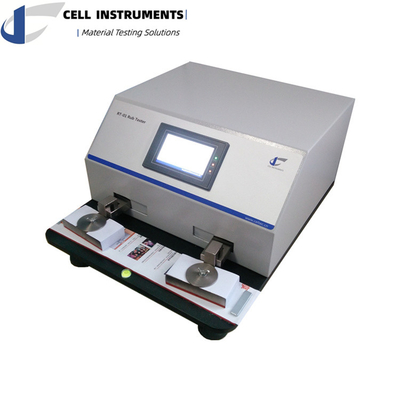

Introducing the RT-01 Rub Tester, a cutting-edge solution brought to you by Cell Instruments, meticulously engineered to evaluate the scuffing or rubbing resistance of ink films or fiber surfaces on container board and corrugated board. This motor-driven marvel offers unparalleled precision and control over testing parameters, making it an indispensable asset for assessing the durability and performance of inks across various applications.

Technical Features of Ink Rub Tester

![]()

- PLC Controlled Unit for Industrial-Level Stability: Equipped with a programmable logic controller (PLC), the RT-01 Rub Tester ensures industrial-grade stability and reliability, guaranteeing consistent and precise testing results crucial for quality assurance in the printing and packaging industries.

- HMI Touch Screen Operation for User-Friendly Experience: Effortlessly operate the RT-01 Rub Tester through its Human-Machine Interface (HMI) touch screen, enhancing user experience and facilitating seamless navigation through testing parameters, thereby boosting operational efficiency.

- Versatile Testing Capabilities: The RT-01 Rub Tester offers a spectrum of testing options including dry rub, wet rub, wet bleed or transfer, wet smear, and functional rub, ensuring adaptability to diverse testing requirements and providing comprehensive insights into ink performance on various surfaces.

- Test Speed Adjustment for Customization: With the ability to adjust test speed according to specific requirements, users can tailor testing protocols based on ink and substrate characteristics, ensuring accurate and reliable results tailored to unique testing needs.

- Double Test Station with Arc Movement Structure: Designed for maximum efficiency, the RT-01 Rub Tester features a double test station with an arc movement structure, enabling simultaneous testing of multiple samples to optimize throughput and productivity.

- Precise Rub Circle Control for Accurate Results: Achieve meticulous control over the rubbing circle with the RT-01 Rub Tester, crucial for obtaining precise and consistent test results, thus ensuring adherence to the highest standards in ink and substrate testing.

Why Choose the RT-01 Rub Tester?

The RT-01 Rub Tester stands as an indispensable tool across industries such as plastics, paper, textile, food, pharmaceuticals, toiletries, printing, and adhesives. This instrument empowers manufacturers and researchers to evaluate ink resistance to rubbing, scuffing, and smearing under varied conditions, providing invaluable insights into ink performance and substrate strength, thereby safeguarding the quality and durability of printed materials and packaging.

Key Purposes of the RT-01 Rub Tester

![]()

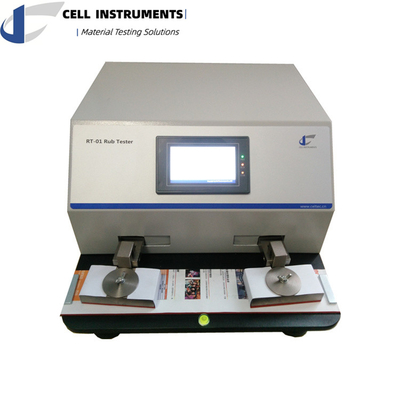

- Ink Resistance: Evaluate ink resistance to both dry and wet rubbing, providing insights into ink maintenance under diverse conditions.

- Surface Strength: Gauge the strength of coated container board, unprinted container board, and similar surfaces, determining their resilience against external forces.

- Smearing and Bleeding: Assess ink smearing or bleeding tendencies, critical for applications where ink stability is paramount for material integrity.

- Heat Resistance: Utilize the heated platen to evaluate ink and varnish performance under elevated temperatures, indicating heat resistance capabilities.

- Adhesion: Differentiate between strong and weak ink films and their adhesion to container board, ensuring longevity and quality of printed materials.

Application of Ink Rub Tester

![]()

Tailored for assessing ink films or fiber surfaces on container board and corrugated board, the RT-01 Rub Tester caters to diverse industries including plastics, paper, textile, food, pharmaceuticals, toiletries, printing, and adhesives. Its versatility ensures that inks meet requisite standards for durability and performance on varied surfaces, making it suitable for testing materials ranging from inks to packaging, labels, coatings, and printed materials.

Standards Compliance of Ink Rub Tester

The RT-01 Rub Tester adheres to stringent industry standards including ASTM D5264, TAPPI T830, ASTM F1571, FINAT FTM 27, ASTM F2497, and JIS K 5701, ensuring compliance with the highest benchmarks for testing and quality control.

Main Parameter

![]()

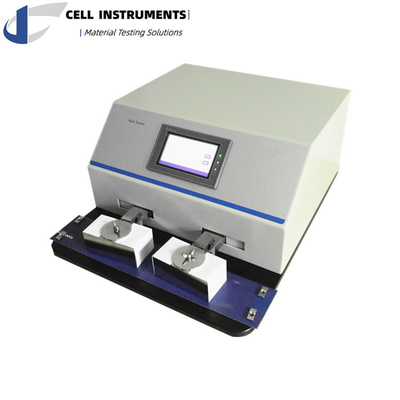

| Weights | 908g (2lb) /8.9N;1816g(4lb) /17.8N |

| Speed | 20~120 cpm free setting |

| Number of Specimens | 1~2 |

| Rotation Radius | 185 mm |

| Arc Length | 57 mm ± 1 mm |

| Dimension | 390x480x220 mm (LWH) |

| Power | 110~220V 50/60Hz |