Multi-Station Heat Seal Tester For BOPP Film Heat Sealable Filmgradient ASTM F2029 Lab Heat Seal Testing Instrument

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Sealing Temp. | Ambient~250℃ | Temp. Gradient | ≤20℃ |

|---|---|---|---|

| Deviation | ±0.2℃ | Sealing Time | 0.1S~9999H |

| Sealing Pressure | 0.15~0.7 MPa | Seal Jaws(mm) | U:40*10 5PCS/L:330 1PCS |

| Gas Input | 0.7 MPa With Ф6 Mm Pipe | Power | AC 220V 50Hz |

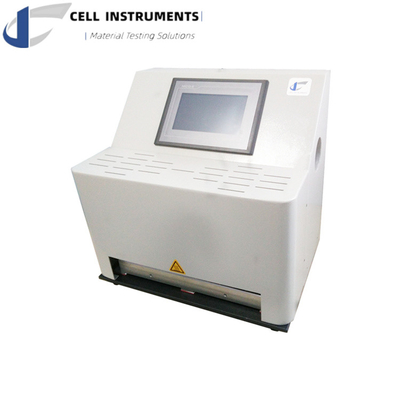

Introduction of GHS-02 Heat Seal Tester

![]()

The GHS-02 Heat Seal Tester from Cell Instruments stands at the forefront of cutting-edge testing technology in the packaging industry. This advanced apparatus is meticulously designed to evaluate the heat-sealing characteristics of a wide array of materials, including films, laminates, and various packaging components. The reliability and strength of heat seals are critical factors influencing the quality and efficiency of packaging across diverse sectors, ranging from food and pharmaceuticals to electronics and more.

Technical Features of GHS-02 Heat Seal Tester

![]()

At the heart of the GHS-02 Gradient Heat Seal Tester lies its unparalleled stability and accuracy in managing time, temperature, and pressure. The PLC control unit and HMI touch screen ensure a state-of-the-art design, allowing for the simultaneous control of five groups of sealing temperatures. Let's delve into its technical features:

- Aluminum Jaws: Both the upper and lower jaws are made of aluminum, ensuring maximum heat retention during sealing and guaranteeing temperature smoothness.

- P.I.D. Temperature Controller: The GHS-02 incorporates a first-class P.I.D. temperature controller for optimal heating management, ensuring precise and consistent temperature conditions.

- Proximity and Pressure Sensor: Achieving accuracy is paramount, and the GHS-02 employs proximity and pressure sensors to ensure controlled dwell time and sealing pressure.

- Guided Sealing Bar: A three-way guided sealing bar ensures uniform sealing pressure, contributing to the reliability and consistency of test results.

- User Protection Designs: The device incorporates user protection features such as an anti-scald front cover, manual and foot switch options, prioritizing safety during operation.

- Customization Options: Seal jaw customization is available in terms of dimensions, shapes, and sealing surface/patterns, allowing for versatility in testing various materials.

- Gradient Temperatures: The GHS-02 offers the capability to customize more gradient temperatures for both upper and lower heating, providing flexibility in testing conditions.

- Connectivity: Seamlessly connect through the RS 232 port and professional software (optional), enhancing the data management capabilities of the device.

Why do you need GHS-02 Heat Seal Tester?

![]()

The GHS-02 Heat Seal Tester is an indispensable tool for manufacturers and researchers in the packaging industry. Its advanced features and customization options make it a necessity for those who prioritize precision, reliability, and efficiency in assessing the heat-sealing characteristics of diverse materials. Whether you are involved in the production of food, pharmaceuticals, textiles, or electronics, the GHS-02 ensures that your packaging meets the highest standards of quality and integrity.

Purpose of the GHS-02 Heat Seal Tester

![]()

The primary purpose of the GHS-02 Heat Seal Tester is to simulate and evaluate the conditions under which heat seals are generated during packaging procedures. By subjecting samples to specific heat, pressure, and time settings, manufacturers can replicate a variety of sealing scenarios. The goal is to identify the optimal parameters for establishing robust and consistent seals, ensuring the long-term quality and effectiveness of the packaged products.

Application

![]()

The GHS-02 Heat Seal Tester finds applications across various industries, including plastics, paper, textiles, food, pharmaceuticals, toiletries, printing, adhesives, and more. Its versatility allows it to be used in research facilities, enterprises, colleges and universities, and official laboratories.

Main Parameter

![]()

| GHS-02 | |

| Sealing Temp. | Ambient~250℃ |

| Temp. Gradient | ≤20℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999H |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws(mm) | U:40*10 5PCS/L:330 1PCS |

| Gas Input | 0.7 MPa with Ф6 mm Pipe |

| Power | AC 220V 50Hz |

Test Process

![]()

Place a sample between two parallel heated sealing jaws with flat surfaces. When the required temperature reaches equilibrium, the upper seal jaw, driven by a gas cylinder, is pushed down to exert a certain pressure on the sample and remain for some time. When the preset sealing time ends, the upper sealing jaw returns to its original position, completing the heatsealability testing process.

Standards

![]()

The GHS-02 Heat Seal Tester adheres to industry standards, with a specific focus on ASTM F2029-16(2021), outlining standard practices for making laboratory heat seals for the determination of heat sealability of flexible barrier materials as measured by seal strength. This ensures that the testing conducted with the GHS-02 aligns with recognized and accepted practices in the packaging industry.