Multi-Station Heat Seal Tester For BOPP Film Heat Sealable Filmgradient ASTM F2029 Lab Heat Seal Testing Instrument

| Sealing Temp. | Ambient~250℃ | Temp. Gradient | ≤20℃ |

|---|---|---|---|

| Deviation | ±0.2℃ | Sealing Time | 0.1S~9999H |

| Sealing Pressure | 0.15~0.7 MPa | Seal Jaws(mm) | U:40*10 5PCS/L:330 1PCS |

| Gas Input | 0.7 MPa With Ф6 Mm Pipe | Power | AC 220V 50Hz |

Multi-Station Heat Seal Tester For BOPP Film Heat Sealable Filmgradient ASTM F2029 Lab Heat Seal Testing Instrument

![]()

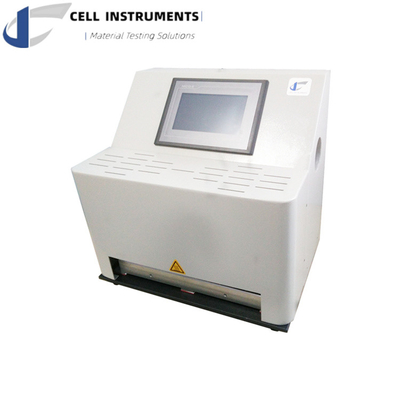

Introduction to the Multi-Station Heat Seal Tester (GHS-02)

The Multi-Station Heat Seal Tester (GHS-02) by Cell Instruments is a state-of-the-art testing solution engineered to evaluate the heat-sealing characteristics of a wide range of packaging materials. It is designed for laboratories, manufacturers, and researchers in industries like food, pharmaceuticals, beverages, and more. This advanced instrument ensures precise, reproducible results for testing heat seal strength, which is crucial for maintaining the integrity and performance of packaging materials.

The GHS-02 Multi-Station Heat Seal Tester allows for comprehensive analysis of various packaging films, laminates, and other materials used in sealing processes. With its ability to simulate real-world packaging conditions, this instrument provides valuable insights into the heat sealing performance under controlled and customizable settings of time, temperature, and pressure.

Key Features of the Multi-Station Heat Seal Tester (GHS-02)

The Multi-Station Heat Seal Tester is packed with advanced features that ensure accurate and reliable testing results. Below are some of its standout technical specifications:

-

Simultaneous Multi-Station Testing:

The GHS-02 can handle up to five different sealing groups simultaneously. This multi-station capability enhances productivity and streamlines the heat seal testing process, allowing for more efficient analysis of multiple material types in parallel. -

Precision Temperature Control:

Equipped with a P.I.D. temperature controller, the GHS-02 ensures precise and stable heating conditions for consistent results across tests. The temperature can be adjusted from ambient to 250°C, with a temperature gradient of less than 20°C. -

Proximity and Pressure Sensors:

The tester features proximity and pressure sensors for accurate sealing pressure and controlled dwell time, crucial for ensuring consistent, reliable seals on various materials. -

Customizable Sealing Jaws:

The Multi-Station Heat Seal Tester offers customizable sealing jaws, allowing users to select dimensions, shapes, and surface patterns that best suit the materials they are testing. This customization ensures flexibility and adaptability across a variety of applications. -

User Safety Features:

For safe operation, the GHS-02 includes anti-scald front covers, manual and foot switch options, and other protective measures, making it a secure tool for laboratory environments. -

Advanced Connectivity:

The tester is equipped with RS 232 ports for seamless data transfer and integration with professional software (optional), ensuring efficient data management and reporting.

Why Choose the GHS-02 Multi-Station Heat Seal Tester?

The Multi-Station Heat Seal Tester is an indispensable tool for laboratories and manufacturers who need to conduct comprehensive and precise heat-seal testing. Whether you are working in the food, pharmaceutical, or electronics industry, the GHS-02 offers the versatility and accuracy needed to ensure your packaging materials meet industry standards for seal strength and durability.

By providing reliable heat-seal test results, the Multi-Station Heat Seal Tester helps manufacturers improve their packaging processes, ensuring that they meet safety, quality, and regulatory requirements. This is particularly crucial in industries like food packaging, where maintaining product integrity is essential for consumer safety.

Applications of the Multi-Station Heat Seal Tester

The GHS-02 Heat Seal Tester is widely used across multiple industries that require accurate and reproducible testing of heat sealable materials. These industries include:

-

Food & Beverage

For testing the seal strength of flexible packaging used in food products to prevent contamination and ensure product freshness. -

Pharmaceuticals

To ensure the reliability of seals on blister packs, pouches, and other pharmaceutical packaging solutions. -

Textiles

For testing fabric laminates and coated textiles used in various types of packaging. -

Electronics

Ensuring that sealing for electronic packaging materials is robust and secure for long-term use. -

Medical Devices

For testing the sealing strength of packaging materials used in medical device sterilization and packaging.

The Multi-Station Heat Seal Tester is also used in research and academic settings for studying the heat-sealing properties of new materials and packaging technologies.

Test Process of the Multi-Station Heat Seal Tester

The test process with the Multi-Station Heat Seal Tester is straightforward and designed for high throughput:

-

Sample Preparation:

Place the sample material between two heated sealing jaws. -

Temperature Control:

Set the desired temperature using the P.I.D. controller, allowing the material to reach equilibrium. -

Sealing Process:

Once the desired temperature is reached, the upper sealing jaw is activated, applying pressure to the sample for the specified dwell time. -

Test Completion:

After the sealing process is complete, the upper jaw retracts, and the sample is removed for analysis of the seal strength.

This simple yet effective test procedure ensures that accurate, reproducible results are achieved, making it a vital tool for quality control in various industries.

Technical Specifications of the Multi-Station Heat Seal Tester

| Parameter | Value |

|---|---|

| Sealing Temperature | Ambient to 250°C |

| Temperature Gradient | ≤ 20°C |

| Temperature Deviation | ±0.2°C |

| Sealing Time | 0.1 seconds to 9999 hours |

| Sealing Pressure | 0.15 to 0.7 MPa |

| Seal Jaw Dimensions | U: 40×10, L: 330 (Customizable) |

| Gas Input | 0.7 MPa with Φ6 mm pipe |

| Power Supply | AC 220V, 50Hz |

Industry Standards and Certifications

The Multi-Station Heat Seal Tester (GHS-02) adheres to the latest industry standards, including ASTM F2029-16(2021). This standard outlines laboratory heat-sealing methods for flexible barrier materials, ensuring that all tests performed with the GHS-02 align with global best practices for heat seal strength determination.

Why Invest in the Multi-Station Heat Seal Tester?

By choosing the GHS-02 Multi-Station Heat Seal Tester, manufacturers and research facilities gain a versatile, precise, and efficient tool that will help them meet the ever-increasing demands of packaging quality control. Whether testing materials for food safety, pharmaceutical integrity, or electronic protection, the GHS-02 offers the performance and reliability you can trust.

![]()