BOPET Coated Film And Other High Barrier Packaging flex durability testing equipment best ASTM F392 tester for sale

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 3.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 3 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

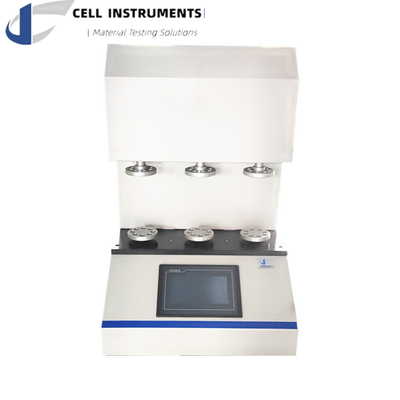

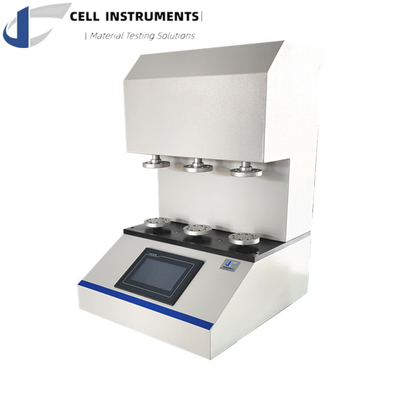

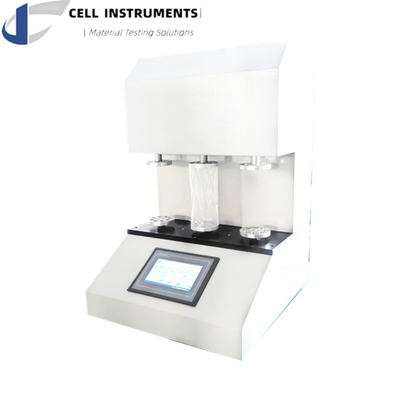

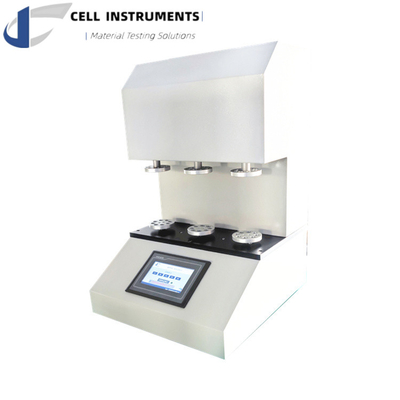

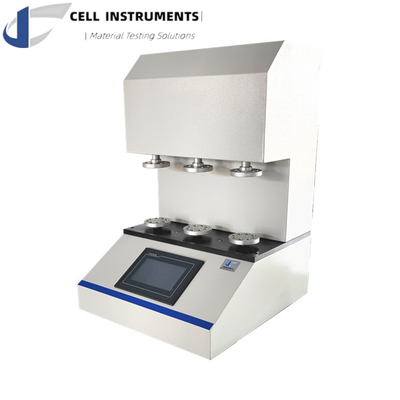

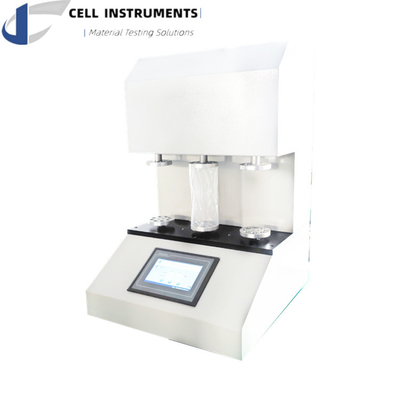

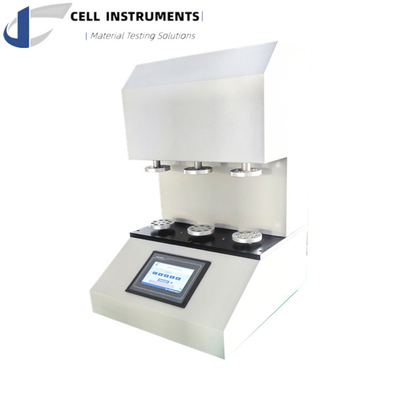

GFT-02 Flex Durability Tester

![]()

Background

![]()

A critical property of flexible barrier materials is their ability to withstand repetitive strain, known as flex durability or Gelboflex resistance. Strong flex crack resistance is essential as it lowers the risk of package perforation during distribution, safeguarding package integrity.

Application

![]()

The flex durability tester, also known as Gelboflex, assesses the ability of materials like films, composites, and coating films to withstand repetitive strain. It quantifies flex failure by detecting pinholes that may develop in the sample structure. Excellent flex crack resistance is vital as it minimizes the risk of packaging developing holes during distribution, ensuring the package remains intact throughout its journey. This is crucial for preserving the integrity of the contents within.

Standards

ASTM F392 "Flex durability of flexible barrier materials"

![]()

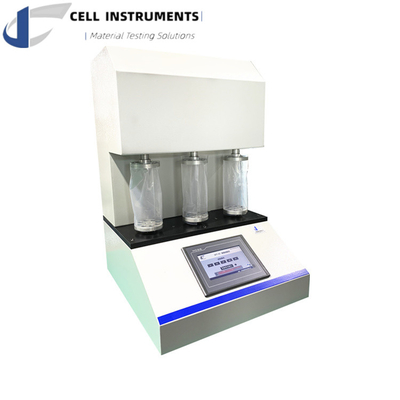

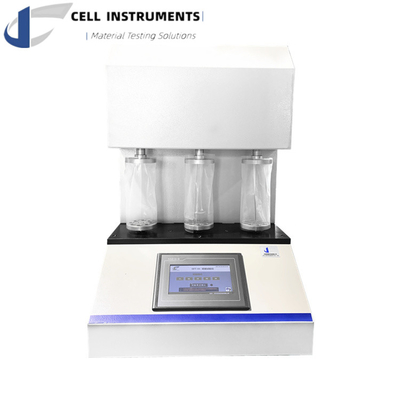

Sampling and motion

![]()

In the flex tester, a sample measuring 200 by 280 mm is affixed to the mandrels. The flexing process involves a combination of twisting and horizontal compression, repeatedly subjecting the film to both actions. Specifically, the setup initiates a twisting motion spanning 440 degrees within the first 90 mm of the stroke, followed by a linear horizontal motion of 65 mm. The entire cycle occurs at a speed of 45 cycles per minute.

Users have the option to select from five pre-programmed test conditions.

Mode A– Full flex for 1 hour (2,700 cycles),

Mode B– Full flex for 20 minutes (900 cycles),

Mode C– Full flex for 6 minutes (270 cycles),

Mode D– Full flex for 20 cycles,

Mode E– Partial flex for 20 cycles.

Technical Features

![]()

The system features PLC control with an intuitive HMI touch screen interface. It offers five standard test modes and includes three test stations. Users can quickly switch between long and short stroke modes. Test conditions A, B, C, D,and E are selectable.

Main Parameter

![]()

| GFT-02 | |

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

FAQ

- Q: What industries can benefit from the GFT-02 Flex Durability Tester?

A: The GFT-02 Flex Durability Tester is applicable to a wide range of industries, including plastics, paper, textile, food, pharmaceuticals, toiletries, printing, adhesives, and more, where flexible barrier materials are crucial for packaging. - Q: How does the GFT-02 Flex Durability Tester simulate repetitive strain?

A: The tester employs a combination of twisting and horizontal compression motions, simulating the repetitive strain that flexible barrier materials may experience during distribution cycles. - Q: Can users customize test conditions with the GFT-02 Flex Durability Tester?

A: While the tester offers five pre-programmed test conditions (Mode A to Mode E), users have the flexibility to choose the most suitable condition for their specific testing requirements. - Q: What is the significance of the ASTM F392 standard in the context of the GFT-02 Flex Durability Tester?

A: The ASTM F392 standard ensures that the testing procedures and results adhere to industry-recognized standards, providing users with confidence in the accuracy and reliability of the GFT-02 Flex Durability Tester.