BOPET Coated Film And Other High Barrier Packaging Flex Durability Testing Equipment Best ASTM F392 Tester For Sale

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 3.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 3 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

BOPET Coated Film And Other High Barrier Packaging Flex Durability Testing Equipment Best ASTM F392 Tester For Sale

![]()

Introduction

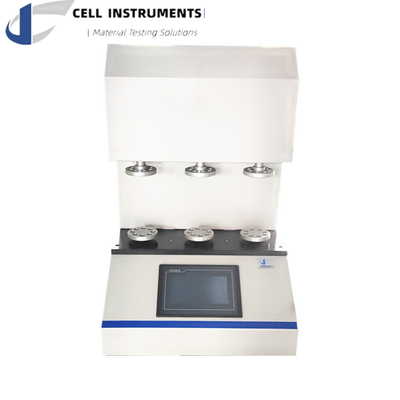

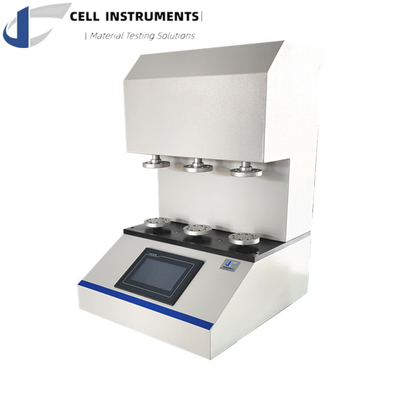

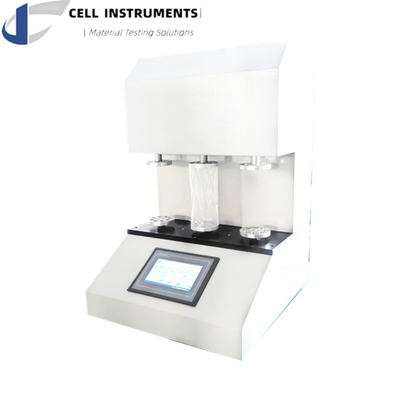

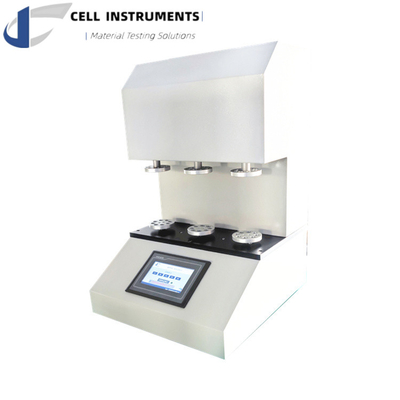

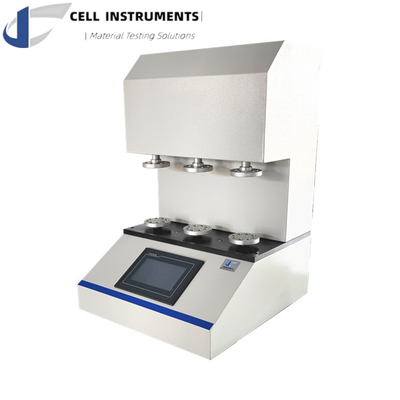

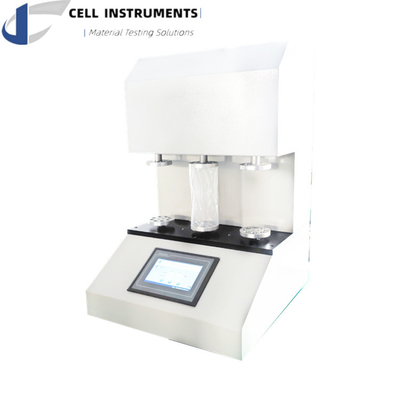

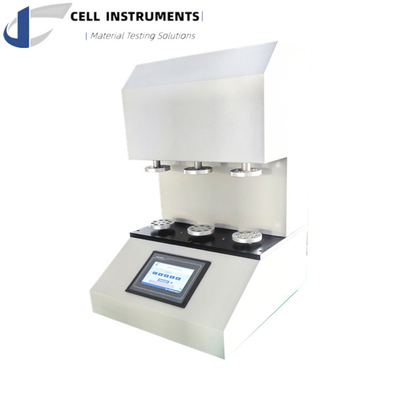

In the realm of flexible packaging, the ability of materials to endure repetitive strain is crucial. This property, known as Barrier Packaging flex durability testing, is vital for ensuring that packaging can withstand the rigors of distribution without compromising the integrity of its contents. The GFT-02 Flex Durability Tester is engineered to assess this key characteristic, making it an indispensable tool for industries reliant on high-quality packaging.

Understanding Barrier Packaging Flex Durability Testing

Barrier Packaging flex durability testing refers to the evaluation of flexible barrier materials to determine their resistance to flex cracking and perforation. This process is essential for materials such as BOPET films, composites, and coated films. By measuring the flex durability, manufacturers can minimize the risk of package failure during transportation, which is critical for maintaining product quality and safety.

Application of the GFT-02 Flex Durability Tester

The GFT-02 Flex Durability Tester is specifically designed to conduct Barrier Packaging flex durability testing. This equipment quantifies flex failure by identifying pinholes or cracks that develop during repeated flexing. A robust flex crack resistance ensures that the packaging remains intact throughout its lifecycle, protecting the contents from exposure and contamination.

Industry Standards

The GFT-02 complies with ASTM F392, which outlines the testing methods for evaluating the flex durability of flexible barrier materials. Adhering to this standard ensures that your testing processes meet recognized industry benchmarks, providing peace of mind and credibility in your product assessments.

Testing Methodology

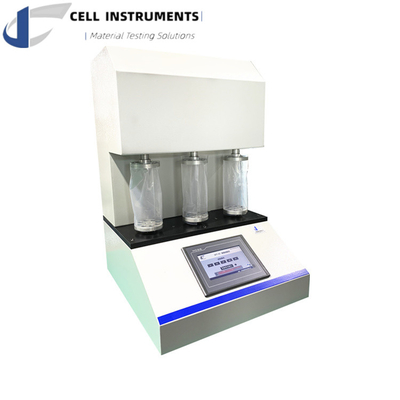

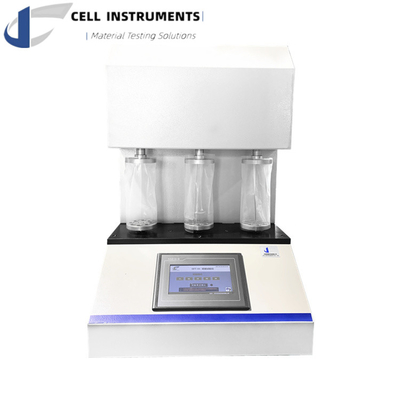

The testing process begins by securing a sample measuring 200 mm x 280 mm onto the machine’s mandrels. The GFT-02 employs a combination of twisting and horizontal compression to simulate real-world conditions. Specifically, the tester initiates a twisting motion of 440 degrees within the first 90 mm of the stroke, followed by a linear motion of 65 mm. This cycle is executed at a rate of 45 cycles per minute, offering five pre-programmed test modes tailored to varying testing needs:

- Mode A: Full flex for 1 hour (2,700 cycles)

- Mode B: Full flex for 20 minutes (900 cycles)

- Mode C: Full flex for 6 minutes (270 cycles)

- Mode D: Full flex for 20 cycles

- Mode E: Partial flex for 20 cycles

Technical Features of the GFT-02

Equipped with an advanced PLC control system and an intuitive HMI touch screen interface, the GFT-02 Flex Durability Tester allows users to effortlessly switch between test modes. The machine features three test stations and supports both long and short stroke modes, enhancing its versatility for various testing scenarios.

Main Parameters

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

Frequently Asked Questions (FAQ)

Q: What industries benefit from the GFT-02 Flex Durability Tester?

A: This tester is ideal for various sectors, including plastics, paper, textiles, food, pharmaceuticals, toiletries, printing, adhesives, and more, where flexible barrier materials are essential for packaging.

Q: How does the GFT-02 simulate repetitive strain?

A: The tester combines twisting and horizontal compression motions to replicate the repetitive strain flexible barrier materials endure during distribution.

Q: Can test conditions be customized with the GFT-02?

A: Yes, users can select from five pre-programmed test conditions (Modes A to E) to tailor the testing process to their specific requirements.

Q: Why is ASTM F392 important for the GFT-02 Flex Durability Tester?

A: Adhering to ASTM F392 ensures that testing methods and outcomes align with recognized standards, instilling confidence in the accuracy and reliability of the results.

![]()