Best Bending Resistance Measurement Instrument for printed paper material ISO 5628 paper bending tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | (0~10000)mN | Bending Length | 5, 10, 15, 20, 25, 30, 40, 50 Mm |

|---|---|---|---|

| Bending Angle | 1 °~ 90 ° | Bending Speed | 0.5~50 ° / S |

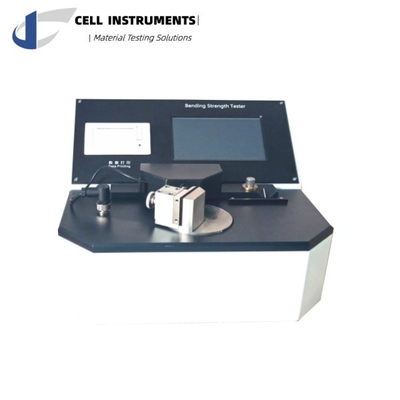

Introduction of WTD-01 Bending Stiffness Tester

![]()

Based on the two-point loading principle, WTD-01 Bending Resistance Tester is used for determining the bending resistance of paper and board. It applies to the measurement of the bending resistance within the range 20 mN to10000 mN. It is not applicable to corrugated board but can be applicable to the components of such board.

Terms

![]()

- Bending force: force required to bend a rectangular test piece clamped at one end.

- Bending resistance: mean of all valid readings of the measured bending force calculated. Bending resistance is expressed in newtons or millinewtons.

- Bending length: constant radial distance between the clamp and the position on the test piece at which the force is applied

- Bending angle: angle through which the clamp rotates while moving from its initial position to the position at which the bending resistance is measured

- Free length: total length of the test piece that projects from the clamp

Why do you need a bending stiffness tester?

![]()

Paper and board bending stiffness is a measure of the material's resistance to bending or deformation. Bending stiffness is crucial in applications where the material needs to maintain its shape or resist deformation, such as in packaging, printing, and various paper-based products. High bending stiffness can contribute to better performance in terms of rigidity and stability.

Technical Features

![]()

- Multi-angle Measurement: Allows for simultaneous setup of up to 3 test angles. Commonly used test angles include 7.5°, 15°, and 30°.

- Bending Time: Offers the flexibility to choose different bending times based on the material's elasticity.

- User Interface: Utilizes a 7-inch touchscreen interface, providing visual menu operation.

- Print Output: Equipped with a modular integrated thermal printer, quick and easy printing of test results.

Test Principle

![]()

Measurement of the force required to bend a test piece clamped at one end through a specified angle, normally 15°, where the force is applied at a specified bending length (50 mm or 10 mm). The bending resistance is calculated as a mean of the measured forces.

Application

![]()

- Packaging: Bending stiffness is important for ensuring that packaging materials maintain their shape and provide adequate protection to the contents.

- Printing: In printing processes, especially high-speed printing, paper with appropriate bending stiffness is desirable to prevent issues such as paper jams.

- Paperboard Products: Products like cartons and display boards benefit from having sufficient bending stiffness for structural integrity.

Specifications

![]()

| Test Range | (0~10000)mN |

| Resolution | 0.1 mN |

| Accuracy | ± 0.5% F.S. |

| Bending Length | 5, 10, 15, 20, 25, 30, 40, 50 mm |

| Bending Angle | 1 °~ 90 ° |

| Bending Speed | 0.5~50 ° / s |

| Speed Accuracy | ± 0.1° |

| Clamp Type | Manual |

| Sample Thickness | 0.01~5mm |

| Sample Size | 38*70mm |

| Screen | 7 in Color Touch Screen |

| Printer | Thermal Type |

| Power | 220 V, 50 Hz |

| Dimension | 380 × 390 × 255 mm LHW |

| Sampling Size |

(70*38)mm Stiffness sample; (38*36)Crease stiffness sample |

| Parallelism | ≤0.015mm |

| Sampling Thickness | (0.1~1.2)mm |

| Dimension | 300*90*90mm |

Configuration

![]()

FAQs

![]()

What are the factors that influence the bending stiffness of paper and board?

- Several factors can influence the bending stiffness of paper and board. Here are key factors that play a role in determining the bending stiffness of these materials:

- Material Thickness: Generally, thicker materials exhibit higher bending stiffness. The thickness of paper or board is a significant factor affecting its ability to resist bending.

- Fiber Type and Orientation: The type of fibers used in the paper or board, as well as their orientation, can impact bending stiffness. Longer and more aligned fibers tend to contribute to higher stiffness.

- Formation of the Sheet: The way fibers are distributed and formed into a sheet can affect bending stiffness. Uniform and well-oriented fiber distribution can contribute to enhanced stiffness.

- Moisture Content: The moisture content of paper and board can influence their flexibility and, consequently, their bending stiffness. Higher moisture levels may reduce stiffness.

- Caliper Uniformity: Caliper refers to the thickness of the material. A uniform caliper across the sheet contributes to consistent bending stiffness.

- Chemical Additives: The presence of certain chemicals, coatings, or additives in the paper or board formulation can affect its mechanical properties, including bending stiffness.

- Temperature and Humidity: Environmental conditions, such as temperature and humidity, can impact the properties of paper and board. Changes in these conditions may alter the bending stiffness.

- Pressing and Drying Processes: The methods used during pressing and drying in the papermaking process can influence the internal structure and, consequently, the bending stiffness of the final product.

- Pulp Composition: The type and blend of pulp used in papermaking play a crucial role. Different pulps have varying fiber lengths, which can affect bending stiffness.

- Coating and Surface Treatments: Coatings or treatments applied to the surface of paper or board can influence its mechanical properties, including bending stiffness.

- Density of the Material: The density of the paper or board can affect its bending stiffness. Higher density often correlates with increased stiffness.