Board Bursting Tester Pressure And Impact Resistance Detection For Paperboard Packaging

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Force Resolution | 1/100000 | Data Analysis Sampling | Sampling Frequency) 400 Times/second |

|---|---|---|---|

| Force Accuracy | ±0.1% (20~100% Full Scale) | Accuracy | ≤±0.5% |

| Resolution | 0.01kpa | Deformation Error | ≤1mm |

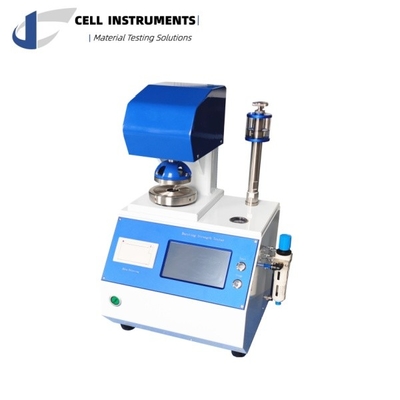

Introduction of BNP-01 Board Bursting Tester

![]()

BNP-01 Board Bursting Tester is used to measure the bursting strength of board submitted to increasing hydraulic pressure. It is applicable to all types of board (including corrugated and solid fiberboard) having bursting strengths within the range 350 kPa to 5 500 kPa, It is also applicable to papers or boards having bursting strengths as low as 250 kPa if the paper or board is to be used to prepare a material of higher bursting strength, such as corrugated board.

Terms

![]()

- Bursting strength: maximum pressure developed by the hydraulic system in forcing an elastic diaphragm through a circular area of the paper when the pressure is applied in the manner described in the method

- Burst index: bursting strength of paper, in kilopascals, divided by the grammage of the paper determined in accordance with ISO 536

Why do you need a Board bursting tester?

The testing of bursting strength in board is a critical means of evaluating the material's resistance to external pressure and impact. This test is significant in understanding the performance of board during packaging, transportation, and handling processes. Bursting strength refers to the ability of board to resist rupture under internal or external pressure. The results reflect the strength and durability of the board, assisting manufacturers in ensuring their products maintain integrity across diverse application scenarios, thereby reducing resource waste and transportation losses due to damage.

Main Parameter

| Item | ZNP-01 Paper Bursting Tester | BNP-01 Board Bursting Tester |

| Measurement Range | 70~1600kpa(paper) | 150 ~5600kpa (board) |

| Force Resolution | 1/100000 | |

| Data Analysis Sampling | Sampling Frequency) 400 times/second | |

| Force Accuracy | ±0.1% (20~100% Full Scale) | |

| Accuracy | ≤±0.5% | |

| Resolution | 0.01kpa | |

| Deformation Error | ≤1mm | |

| Concentricity of Upper and Lower Plates | ≤0.25mm | |

| Diaphragm Resistance | (9±0.2)mm/(30±5)kPa | |

| Oil Feeding Speed | 95±5ml/min(paper) | 175±5ml/min(board) |

| Platen Diameter | Upper:30.5±0.1mm ; | Upper:31.5±0.1mm ; |

| Lower:33.1±0.1mm(paper) | Lower:31.5±0.1mm(board) | |

| Air Source | 0.6~0.7Mpa | |

| Display | 5in Touch Screen | |

| Testing Control | Equipped with delayed pressurization control and pressure release delay control. | |

| Clamping Force | Adjustable pressure range from 100kPa to 1200kPa with a stabilizing function to ensure consistent clamping force. | |

| Oil Cup System | High-Strength High-Pressure Oil Circuit Sealing System with Dual Sealing Knobs, (25mm High-Pressure 304 Stainless Steel Oil Pipe | |

| Circuit Board Chip Protection | Equipped with a built-in water vapor filtration device to ensure the stability of the circuit. | |

| Calibration System | Includes a built-in calibration system and a self-contained manual pressure and pressure release control system. | |

| Material of Testing Head | The oil cylinder section, upper clamping, and lower clamping parts are all made of 304 stainless steel. | |

| Safety Devices | Comes with a protective cover and a power supply anti-interference protection module. | |

| Language Switching | Allows for free switching between Chinese and English languages. | |

| Unit Conversion | Kg/cm2,kpa,lbf/in2 | |

| Print Output | Modular Integrated Thermal Printer | |

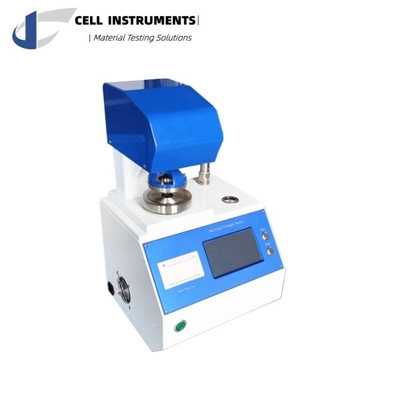

Advantages of BNP-01 Board Bursting Tester

![]()

- Human-Machine Interface: Equipped with a 5-inch touchscreen for user interaction.

- Testing Control: Features delayed pressurization control and pressure release delay control.

- Clamping Force: Adjustable clamping force ranging from 100kPa to 1200kPa, with stabilizing functionality to ensure consistent clamping force.

- Oil Cup System: Utilizes a high-strength, high-pressure oil circuit sealing system, including dual-seal knobs and a 25mm high-pressure 30 stainless steel oil pipe.

- Circuit Board Chip Protection: Integrated with a water vapor filtration device to safeguard the stability of the circuit.

- Calibration System: Includes a built-in calibration system and a self-contained manual pressure and pressure release control system.

- Testing Head Material: The cylinder section, upper clamping, and lower clamping parts are constructed from 304 stainless steel.

- Safety Features: Comes with a protective cover and a power supply anti-interference protection module.

- Language Switching: Supports free switching between Chinese and English languages.

- Unit Conversion: Allows unit conversion between Kg/cm2, kPa, and lbf/in2.

- Print Output: Equipped with a modular integrated thermal printer for convenient printing.

Test Principle

![]()

A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure.

Board Bursting Test Standards

![]()

GB 1539, GB 6545, ISO 2759, TAPPI T 810, TAPPI T 807,QB/T 1057

Configuration

![]()

- Standard configuration: BNP-01 Board Bursting Tester, wrench, silicone oil (not available for air shipping), rubber diaphragm, foil, paper roll, manual, calibration certificate, power cord.

- Optional configuration: extra diaphragm, extra foil, COM Line, Software, air compressor

FAQs

![]()

- What is Paper and Paperboard Bursting Strength?

Bursting Strength refers to the ability of paper and paperboard materials to withstand bursting or breaking when subjected to external forces, typically measured using a bursting strength tester. The result indicates the maximum force that the paper or paperboard can resist per unit area before rupturing, providing insights into the material's structural strength and durability, particularly relevant in the context of packaging and transportation. - Why is the bursting test always referred to as Mullen Method?

The Mullen Method is named after one of its founders, Emory H. Mullen. Emory H. Mullen, along with other engineers, developed the Bursting Tester in the United States in 1926, which is a specialized instrument for measuring the bursting strength of paper and paperboard. Due to his contributions to the development and promotion of this testing method, it became known as the Mullen Method.

The introduction of the Mullen Method provided the paper and paperboard industry with a standardized and repeatable way to measure a material's resistance to bursting under pressure. This testing method is widely used in the packaging and related industries to assess the strength of materials, especially when considering the stresses they may undergo during transportation and packaging processes.