CWY-01 Concora Medium Fluter High-Precision Corrugated Board Sampling Machine with CCT & CMT Testing Capabilities

| Depth Of Teeth | 4.75+/-0.05mm | Distance Between Teeth | 8.50 ± 0.05 Mm |

|---|---|---|---|

| Flute Type | A (standard) | Speed | 4.5 ± 0.1 R/min |

| Sample Width | 12.7 Mm | Pressure Range | 50-140 N Force Indication Accuracy ± 2 N |

| Temperature Range | Ambient~200℃ | Standard Working Temperature | 175 ℃ ± 8℃ |

| Temperature Resolution | 1℃ | Power | AC 220V 50Hz |

CWY-01 Concora Medium Fluter High-Precision Corrugated Board Sampling Machine with CCT & CMT Testing Capabilities

![]()

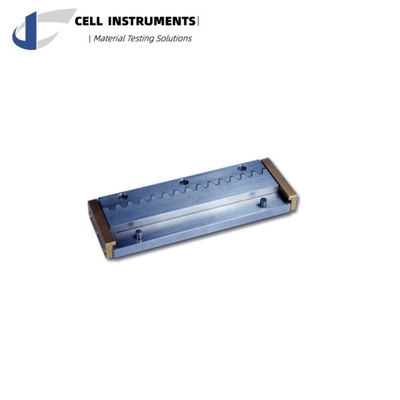

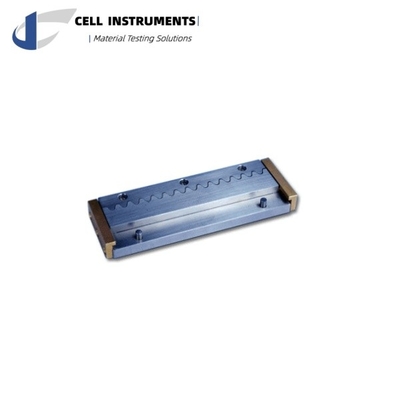

Introduction to the CWY-01 Corrugated Board Sampling Machine

The CWY-01 Corrugated Board Sampling Machine is an advanced testing instrument designed for laboratories involved in material testing, specifically for corrugated board. This machine adheres to industry standards for A flute and other optional flutes, providing a reliable method for preparing samples used in critical testing processes.

With the CWY-01, users can efficiently produce 0.5 inch (12.7 mm) wide samples essential for determining the compressibility strength of corrugated materials. This testing machine employs both the Corrugated Crush Test (CCT) and the Corrugating Medium Test (CMT) to deliver precise and accurate results.

Test Principle of the Corrugated Board Sampling Machine

The operation of the Corrugated Board Sampling Machine is straightforward yet effective. After powering on the machine and setting the desired temperature, users must wait for the disc temperature to stabilize at the preset value. Once ready, the sample is placed into the machine, and the corrugated sample is extruded from the bottom.

These samples are then paired with the appropriate CMT rack and comb or CCT sample holder for analysis. A high-precision compressive strength tester evaluates the sample, ensuring reliable data collection for further analysis.

Key Features of the CWY-01 Corrugated Board Sampling Machine

- Rugged and Durable Construction: Built to withstand rigorous testing environments, this machine promises longevity and reliability.

- Interchangeable Corrugating Discs: Different discs can be replaced according to the specific testing requirements, enhancing versatility.

- Adjustable Pressure Range: The machine features a calibration option, allowing users to adjust pressure settings from 50 to 140 N, ensuring accurate force application.

- Vertical Design for Simplified Operation: The vertical configuration allows for easy sample feeding, reducing operator strain and improving efficiency.

- Integrated Heating System: Built-in heating elements provide rapid and uniform temperature distribution, essential for effective sample preparation.

- Precise Temperature Control: The machine boasts a temperature range from ambient to 200℃, with a standard working temperature of 175℃ ± 8℃ and a resolution of 1℃.

- Space-Saving Design: Optimally designed for laboratory settings, it occupies minimal space without compromising functionality.

Main Parameters of the CWY-01 Corrugated Board Sampling Machine

| Radius Of Teeth At Peak | R 1.5 士 0.1mm |

| Radius Of Teeth At Base | R 2.0 士 0.1mm |

| Depth Of Teeth | 4.75+/-0.05mm |

| Distance Between Teeth | 8.50 ± 0.05 mm |

| Flute Type | A (standard) |

| Speed | 4.5 ± 0.1 r/min |

| Sample Width | 12.7 mm |

| Pressure Range | 50-140 N Force indication accuracy ± 2 N |

| Temperature Range | Ambient~200℃ |

| Standard Working Temperature | 175 ℃ ± 8℃ |

| Temperature Resolution | 1℃ |

| Power | AC 220V 50Hz |

![]()