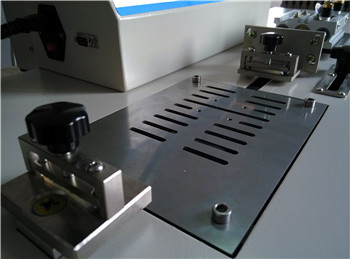

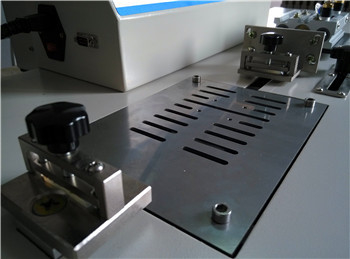

Hot Tack Peeling Tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Sealing Temp. | Ambient~250℃ | Temp Accuracy | ±0.2℃ |

|---|---|---|---|

| Dwell Time | 0.1~9999s(Hot Tack ) | Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated | ||

| Highlight | hot tack,peeling,tensile |

||

Product Description

Discover unparalleled precision and reliability in evaluating the hot tack strength of heat-sealed layers with the HTT-01 Hot Tack Tester. Crafted by Cell Instruments, this advanced solution caters to industries spanning plastics, paper, textile, food, pharmaceuticals, toiletries, printing, and adhesives. The HTT-01 is not just a hot tack tester; it's a comprehensive instrument offering multifunctionality and versatility for diverse testing needs.

Technical Features of HTT-01 Hot Tack Tester

- PLC Controlled Industrial Stability: Experience industrial-level stability with precise control, thanks to the Programmable Logic Controller (PLC).

- HMI Touch Screen Interface: Effortlessly navigate and control the testing process through the intuitive Human-Machine Interface (HMI) touch screen.

- Versatile Functionality: Seamlessly integrate hot tack, tensile, and peeling tests into a single unit, meeting various testing requirements across packaging and industrial sectors.

- Temperature Control Precision: Ensure accuracy and consistency in maintaining desired temperatures during testing with the Delta P.I.D. temperature controller and PT100 temperature sensor.

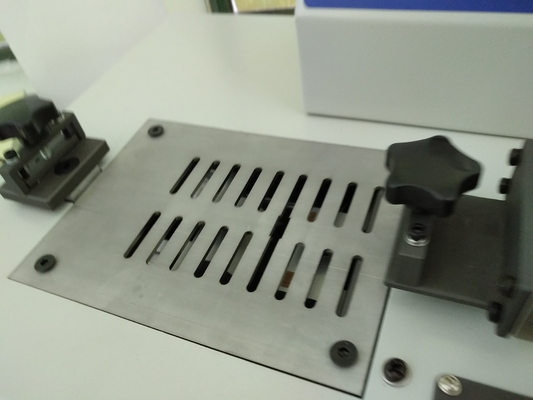

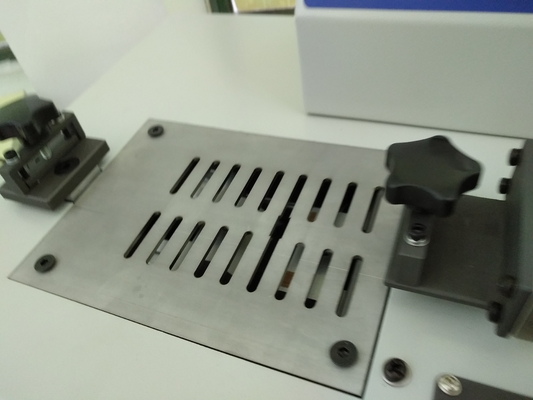

- Durable Sealing Jaws: The robust aluminum encapsulated sealing jaws, coated with Teflon, ensure uniform and reliable sealing across different materials.

- Adjustable Testing Speed: Tailor testing conditions to specific requirements with an adjustable testing speed ranging from 1 to 2000 mm/min.

- Safety Features: Integrated auto zeroing, overload protection, and over-travel protection ensure a secure testing environment and prevent potential damage during operation.

- Optional RS 232 Port and Professional Software: Enhance data management capabilities with an optional RS 232 port and professional software for comprehensive insights into testing outcomes.

Why Choose HTT-01 Hot Tack Tester?

The HTT-01 Hot Tack Tester is an indispensable tool for industries prioritizing packaging integrity. Its multifunctionality, precision, and safety features make it a vital asset for quality control in packaging processes.

Purpose of HTT-01 Hot Tack Tester

The primary purpose of the HTT-01 Hot Tack Tester is to evaluate the hot tack strength of heat-sealed layers, particularly crucial in vertical form-fill-seal (VFFS) processes. Additionally, it serves as a horizontal tensile and peeling force tester, ensuring overall reliability and integrity of seals across various materials.

Application of HTT-01 Hot Tack Tester

Ideal for vertical form-fill-seal (VFFS) packaging applications, the HTT-01 ensures seal integrity under immediate product loading, preventing package failures.

Standards

Complying with industry standards such as ASTM F1921 and ASTM F2029, the HTT-01 Hot Tack and Tensile Tester ensures reliability and reproducibility of test results.

![]()

Hot Tack Peeling Tester Features

- Hot tack, heat seal, peeling and tensile test items are integrated in one instrument

- Sealing jaws are controlled by P.I.D. temperature. Temperature rises fast to set temp and keeps stable

- 7 inch TFT touching screen for easy operation

- PLC control

- Aluminum encapsulated sealing jaws for average heating

- Multi-group parameter saving

- Any testing speed adjustable

- Auto zeroing, overload and over travel protection

- Manual and foot switch starting test, anti-scald design

- RS 232 port and professional software

![]()

Hot Tack Peeling Tester Technical Specifications

|

Items |

Parameters |

|

Sealing Temperature |

Ambient~250℃ |

|

Temp Accuracy |

±0.2℃ |

|

Heat Seal Dwell Time |

0.1~9999s |

|

Hot Tack Dwell Time |

0.1~9999s |

|

Sealing Pressure |

0.05MPa~0.7MPa |

|

Sealing Jaws |

50mmx10mm Teflon Coated |

|

Sealing Jaws Heating |

Double Heating |

|

Load Cell |

200N Optional:30N50N100N500N) |

|

Accuracy |

0.5 F.S. |

|

Resolution |

0.01N |

|

Stroke |

500mm |

|

Gas Source |

0.5MPa~0.7MPa |

|

Port Size |

Ф6mm PU Hose |

|

Dimensions |

1100mm(L)×390mm(W)×420(H) |

|

Power |

AC220V50Hz |

Hot Tack Peeling Tester Standards

ASTM F1921, ASTM F2029, QB/T2358, YBB 00122003