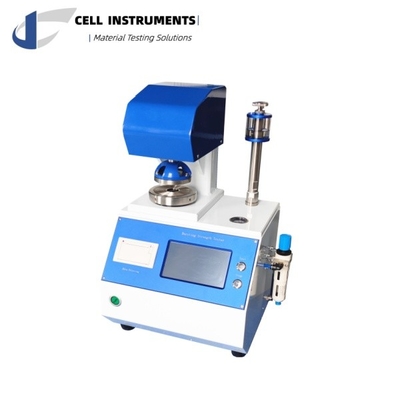

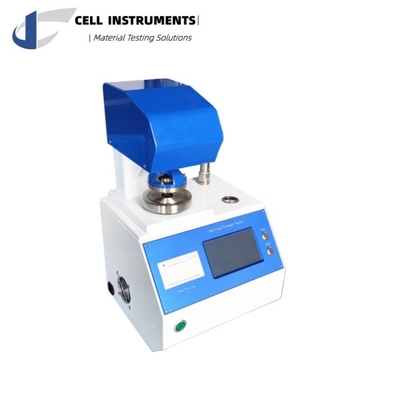

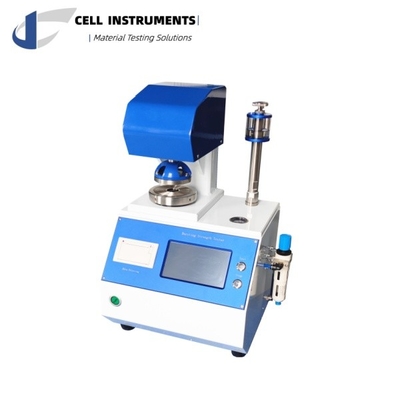

Paper Bursting Tester Pressure And Impact Resistance Detection For Paper Packaging Paper Bursting Resistance Tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Force Resolution | 1/100000 | Data Analysis Sampling | Sampling Frequency) 400 Times/second |

|---|---|---|---|

| Force Accuracy | ±0.1% (20~100% Full Scale) | Accuracy | ≤±0.5% |

| Resolution | 0.01kpa | Deformation Error | ≤1mm |

Paper Bursting Tester Pressure And Impact Resistance Detection For Paper Packaging Paper Bursting Resistance Tester

![]()

The ZNP-01 Paper Bursting Tester is an advanced instrument designed for accurately measuring the bursting strength of paper under increasing hydraulic pressure. This essential testing device is highly applicable in industries like packaging, food, medicine, and more, where the durability and strength of paper materials are crucial for ensuring product safety and quality. The ZNP-01 is suitable for paper materials with bursting strengths ranging from 70 kPa to 1400 kPa, providing critical data for manufacturers and quality control teams.

What is the Paper Bursting Tester Used For?

The Paper Bursting Tester plays a vital role in evaluating the structural integrity of paper, particularly in packaging applications. It ensures that the selected paper materials can withstand external pressures and impacts, reducing the risk of damage during transit and handling. By performing regular bursting strength tests, manufacturers can improve their production quality, maintain high standards, and meet industry regulations. This is particularly important for paper used in packaging food, pharmaceuticals, and other sensitive products.

Why Choose the ZNP-01 Paper Bursting Tester?

The ZNP-01 Paper Bursting Tester offers a wide range of features that make it a reliable and accurate solution for measuring bursting strength in the laboratory:

- Human-Machine Interface: The Paper Bursting Tester is equipped with a 5-inch touchscreen, providing an easy-to-use interface for users.

- Testing Control: Features include delayed pressurization control and pressure release delay control, ensuring precise and repeatable testing results.

- Adjustable Clamping Force: The clamping force can be adjusted from 100 kPa to 1200 kPa, with stabilizing functionality to maintain consistent clamping force during tests.

- High-Strength Oil Cup System: The high-pressure oil circuit sealing system includes dual-seal knobs and stainless steel pipes for maximum durability.

- Calibration and Safety: Built-in calibration and manual control systems are included, as well as a protective cover and power supply anti-interference protection for safety.

- Multiple Language Support: The device supports both English and Chinese language options for convenience.

How Does the Paper Bursting Tester Work?

The ZNP-01 Paper Bursting Tester operates by placing a test piece of paper over a circular elastic diaphragm. The paper is clamped at the edges, while the diaphragm is free to bulge under hydraulic pressure. As the hydraulic fluid is pumped into the system, the diaphragm expands until the paper ruptures. The maximum hydraulic pressure applied at the point of rupture is recorded as the bursting strength of the paper.

Key Parameters of the ZNP-01 Paper Bursting Tester:

| Item | ZNP-01 Paper Bursting Tester | BNP-01 Board Bursting Tester |

| Measurement Range | 70~1600kpa(paper) | 150 ~5600kpa (board) |

| Force Resolution | 1/100000 | |

| Data Analysis Sampling | Sampling Frequency) 400 times/second | |

| Force Accuracy | ±0.1% (20~100% Full Scale) | |

| Accuracy | ≤±0.5% | |

| Resolution | 0.01kpa | |

| Deformation Error | ≤1mm | |

| Concentricity of Upper and Lower Plates | ≤0.25mm | |

| Diaphragm Resistance | (9±0.2)mm/(30±5)kPa | |

| Oil Feeding Speed | 95±5ml/min(paper) | 175±5ml/min(board) |

| Platen Diameter | Upper:30.5±0.1mm ; | Upper:31.5±0.1mm ; |

| Lower:33.1±0.1mm(paper) | Lower:31.5±0.1mm(board) | |

| Air Source | 0.6~0.7Mpa | |

| Display | 5in Touch Screen | |

| Testing Control | Equipped with delayed pressurization control and pressure release delay control. | |

| Clamping Force | Adjustable pressure range from 100kPa to 1200kPa with a stabilizing function to ensure consistent clamping force. | |

| Oil Cup System | High-Strength High-Pressure Oil Circuit Sealing System with Dual Sealing Knobs, (25mm High-Pressure 304 Stainless Steel Oil Pipe | |

| Circuit Board Chip Protection | Equipped with a built-in water vapor filtration device to ensure the stability of the circuit. | |

| Calibration System | Includes a built-in calibration system and a self-contained manual pressure and pressure release control system. | |

| Material of Testing Head | The oil cylinder section, upper clamping, and lower clamping parts are all made of 304 stainless steel. | |

| Safety Devices | Comes with a protective cover and a power supply anti-interference protection module. | |

| Language Switching | Allows for free switching between Chinese and English languages. | |

| Unit Conversion | Kg/cm2,kpa,lbf/in2 | |

| Print Output | Modular Integrated Thermal Printer | |

Paper Bursting Test Standards

The ZNP-01 Paper Bursting Tester complies with various international standards, including:

- GB/T 454

- QB/T 1057

- ISO 2758

- TAPPI T 403

- JIS P 8112

- BS 3137

- ASTM D774

Advantages of Using the ZNP-01 Paper Bursting Tester

The ZNP-01 Paper Bursting Tester brings several advantages to the testing process, making it an ideal choice for laboratories and manufacturers:

- Accurate Testing: Provides reliable measurements of paper’s bursting strength, which is critical for packaging integrity.

- Durable and Reliable: Built with high-quality materials, including stainless steel components, ensuring long-term performance.

- Ease of Use: User-friendly interface with touchscreen controls, making it accessible even for operators with minimal experience.

- Safety: Equipped with protective mechanisms to safeguard both users and the equipment.

Applications of the Paper Bursting Tester

The ZNP-01 Paper Bursting Tester is widely used in various industries where paper packaging and materials are critical. Some key applications include:

- Packaging Industry: Ensures that paper packaging materials are strong enough to withstand transport and handling stresses.

- Food Packaging: Tests paper used in food packaging to prevent contamination and maintain product safety during transit.

- Pharmaceutical Packaging: Verifies the durability of paper materials in pharmaceutical packaging to ensure product integrity.

- Quality Control: Serves as a critical tool in manufacturing to maintain high-quality standards and meet industry specifications.

FAQs About the Paper Bursting Tester

-

What is Paper Bursting Strength?

- Paper bursting strength refers to the maximum pressure a piece of paper can withstand before rupturing. It is an essential measure of paper’s durability and performance under stress, particularly important in packaging applications.

-

Why is Paper Bursting Strength Testing Important?

- Bursting strength testing is crucial for ensuring the quality and reliability of paper materials used in packaging. It helps manufacturers select materials that will resist breaking during handling and transport, minimizing product loss or damage.

-

What Standards are Used in Paper Bursting Testing?

- The ZNP-01 Paper Bursting Tester complies with global standards such as ISO 2758, ASTM D774, and TAPPI T 403, ensuring that your results are accurate and industry-compliant.

-

Can the ZNP-01 Paper Bursting Tester Be Used for All Types of Paper?

- The ZNP-01 is designed for testing paper with bursting strengths ranging from 70 kPa to 1400 kPa. It is not suitable for testing combined board materials like fluting or linerboard.

-

What are the Calibration Requirements for the ZNP-01?

- The ZNP-01 comes with a built-in calibration system, allowing users to calibrate the tester easily. Regular calibration ensures accurate and reliable test results.

![]()