Corrugated Base Paper Corrugator For Corrugated Core Flat Pressing And Corrugated Vertical Pressing Testing

| Depth Of Teeth | 4.75+/-0.05mm | Distance Between Teeth | 8.50 ± 0.05 Mm |

|---|---|---|---|

| Flute Type | A (standard) | Speed | 4.5 ± 0.1 R/min |

| Sample Width | 12.7 Mm | Pressure Range | 50-140 N Force Indication Accuracy ± 2 N |

| Temperature Range | Ambient~200℃ | Standard Working Temperature | 175 ℃ ± 8℃ |

| Temperature Resolution | 1℃ | Power | AC 220V 50Hz |

Corrugated Base Paper Corrugator For Corrugated Core Flat Pressing And Corrugated Vertical Pressing Testing

![]()

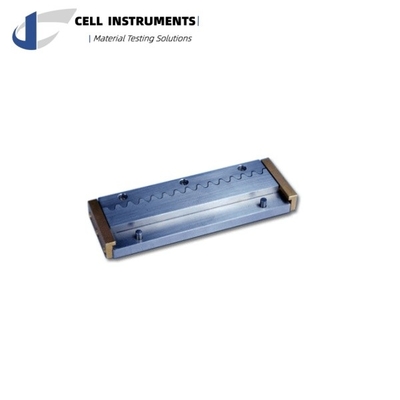

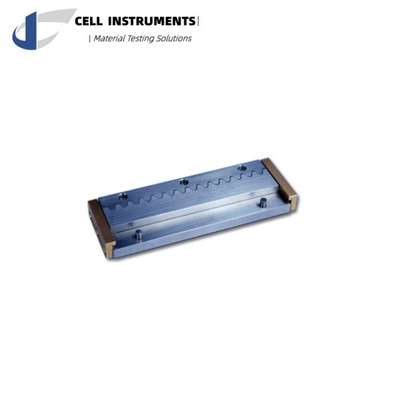

Introduction to CWY-01 Concora Medium Fluter

The CWY-01 Concora Medium Fluter, a highly efficient Corrugated Base Paper Corrugator, is essential for testing the strength and durability of corrugated board materials. This versatile machine is designed specifically for laboratory environments that require precise sampling of corrugated boards. By producing uniform flute samples, it supports critical tests like the Corrugated Crush Test (CCT) and Corrugating Medium Test (CMT), providing accurate and reliable results. The CWY-01 Corrugated Base Paper Corrugator is widely used across industries such as packaging, food, pharmaceuticals, and academic institutions for corrugated board quality control and research.

The machine’s standard flute type is A, but it can also accommodate other optional flute configurations, making it flexible for various testing needs. The Corrugated Base Paper Corrugator produces a 12.7 mm wide sample with exceptional precision, thanks to its two advanced corrugating discs. These discs feature an even heat distribution mechanism, crucial for forming accurate corrugations, ensuring optimal sample quality for testing.

Test Principle of the CWY-01 Corrugated Base Paper Corrugator

The operation of the CWY-01 Corrugated Base Paper Corrugator is straightforward yet highly efficient. After setting the desired temperature, the machine begins to heat the corrugating discs to the pre-set level. Once the temperature is stabilized, the sample is inserted from the top. As the sample moves through the corrugating discs, it is formed into the desired flute shape and exits from the bottom.

The corrugated sample is then ready for further testing using either the CMT (Corrugating Medium Test) rack and comb or the CCT (Corrugated Crush Test) sample holder. These testing processes are typically conducted using a high-precision compressive strength tester, which determines the strength and resilience of the corrugated board sample. This makes the CWY-01 Corrugated Base Paper Corrugator an indispensable tool for quality assurance and research labs focused on corrugated material performance.

Key Features of CWY-01 Corrugated Base Paper Corrugator

- Durable and Robust Design: Built for long-term use in demanding laboratory environments, this Corrugated Base Paper Corrugator offers superior durability and reliability.

- Replaceable Corrugating Discs: The corrugating discs can be easily replaced, allowing for flexibility and adaptability in different test conditions and flute types.

- Adjustable Pressure Range: Users can calibrate and adjust the pressure range based on the specific testing requirements. The wide range of pressure settings ensures versatile application across various corrugated materials.

- Vertical Design for Easy Sample Feeding: The vertically aligned sample feeding system simplifies the operation, making it more ergonomic and efficient for users.

- Advanced Heating Mechanism: The built-in heating element within the corrugating discs ensures fast and uniform temperature distribution, critical for achieving accurate flute formation.

- Precise Temperature Control: The CWY-01 Corrugated Base Paper Corrugator offers highly accurate temperature regulation, with a resolution of 1°C, ensuring consistent test results.

- Space-Saving Design: The compact footprint of the machine makes it suitable for labs with limited space, while still providing powerful performance.

Main Technical Parameters

| Radius Of Teeth At Peak | R 1.5 士 0.1mm |

| Radius Of Teeth At Base | R 2.0 士 0.1mm |

| Depth Of Teeth | 4.75+/-0.05mm |

| Distance Between Teeth | 8.50 ± 0.05 mm |

| Flute Type | A (standard) |

| Speed | 4.5 ± 0.1 r/min |

| Sample Width | 12.7 mm |

| Pressure Range | 50-140 N Force indication accuracy ± 2 N |

| Temperature Range | Ambient~200℃ |

| Standard Working Temperature | 175 ℃ ± 8℃ |

| Temperature Resolution | 1℃ |

| Power | AC 220V 50Hz |

Benefits of Using CWY-01 Corrugated Base Paper Corrugator

The CWY-01 Corrugated Base Paper Corrugator is designed to help industries ensure the quality and durability of corrugated packaging materials. Testing the compressive strength of corrugated boards is essential for manufacturers in the packaging, food, pharmaceutical, and beverage industries, where packaging integrity directly impacts product safety and transportation efficiency.

The device’s precision and robust design help ensure that every sample is corrugated to exact specifications, providing reliable data on the strength and performance of the materials being tested. As the demand for high-quality packaging materials increases, the CWY-01 Corrugated Base Paper Corrugator serves as a critical tool in meeting industry standards.

Industries that Benefit from Corrugated Base Paper Corrugator

- Packaging Industry: Ensuring corrugated boxes and materials meet strength requirements to protect goods during transit.

- Food & Beverage Industry: Testing corrugated packaging materials to ensure they withstand storage and handling conditions.

- Pharmaceuticals: Evaluating the robustness of packaging for drugs and medical supplies.

- Educational and Research Institutions: Facilitating research into the durability of packaging materials and contributing to material innovation.

How the CWY-01 Corrugated Base Paper Corrugator Supports Compliance with Industry Standards

The CWY-01 Corrugated Base Paper Corrugator is designed to align with international testing standards, making it suitable for labs aiming to achieve ISO certification or comply with industry-specific regulations. Its ability to produce consistent and accurate test samples ensures that testing results are reliable and can be used to improve packaging designs or ensure compliance with stringent quality requirements.

![]()