Smoothness Tester Paper And Board Smoothness Tester

| Power | Electronic | Usage | Paper Testing Instrument |

|---|---|---|---|

| Application | Paper And Boards,paper Or Board,plastic,textile |

Smoothness Tester Paper And Board Smoothness Tester

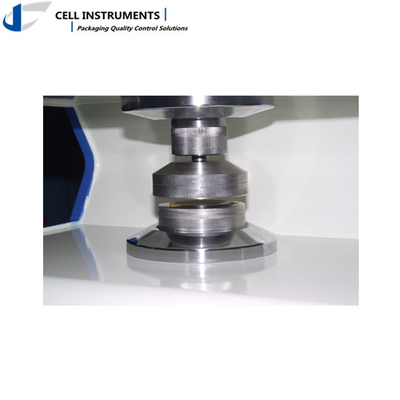

The Board Smoothness Tester is a highly precise instrument designed to measure the smoothness of paper and board materials. It plays a crucial role in quality control across industries such as packaging, printing, food packaging, pharmaceutical packaging, and other material testing applications. The Board Smoothness Tester is based on the Bekk method, which is internationally recognized and widely used for determining the smoothness of paper and board. This instrument provides accurate, repeatable results, essential for ensuring the high quality and consistency of materials in industrial processes.

Key Features and Benefits of the Board Smoothness Tester

-

Accurate Smoothness Measurement: The Board Smoothness Tester measures smoothness based on the Bekk method, which determines how quickly air can be drawn through the surface of the paper or board under a specified pressure differential. The result is a smoothness value that can be directly correlated to the material's performance in applications such as printing, packaging, and other industrial uses.

-

Wide Measurement Range: The Board Smoothness Tester offers a broad measurement range from 1 second to 9999 seconds, making it suitable for various types of paper and board materials with different smoothness levels.

-

Compliant with Industry Standards: This tester adheres to international standards, including ISO 527, DIN 53107, TAPPI T-479, and GB/T 456, ensuring reliability and accuracy for compliance in global markets.

-

Flexible Testing Options: The device provides multiple vacuum settings, offering flexibility in testing materials with different surface textures. It supports three different gears to measure varying levels of smoothness in paper and board products.

-

Automatic Pressure Control: The Board Smoothness Tester features an automatic pressure control system, ensuring consistent test conditions and eliminating the need for manual adjustments, which enhances test accuracy.

-

User-Friendly Interface: Designed for easy use, the tester provides clear, quick readings. With minimal setup, it allows users to obtain smoothness measurements in just a few simple steps, making it a valuable addition to any laboratory or production facility.

-

Power Efficiency: The tester operates on a standard AC220V, 50Hz power supply, ensuring efficient energy consumption while providing reliable results.

How the Board Smoothness Tester Works

The Board Smoothness Tester works based on the Bekk smoothness method, which measures the time required for a specific volume of air to pass through a defined test area of paper or board under a set pressure differential. The measurement is recorded in seconds and is a direct indicator of the material's surface smoothness. The smoother the material, the less time it takes for the air to flow through the test area.

The tester uses a vacuum system to create a pressure differential between the test piece and the measuring surface. By controlling the vacuum and measuring the time it takes for air to pass through the material, the device calculates the smoothness value according to the Bekk method.

Technical Specifications of the Board Smoothness Tester

| Test area | (10±0.05) cm² |

| Measuring range | (1-9999)S, (1-15)S, (15~300) S, (300~9999) S, three range switch |

| Volume | Big Vacuum 380±1ml; Small Vacuum (38±1) ml |

| Vacuum range | I gear 50.66kPa -> 29.33kPa |

| II gear 50.66kPa -> 48kPa | |

| III gear:50.66kPa -> 48kPa | |

| Test Pressure | (100±2) kPa (Automatic pressure) |

| Dimension | 380x360x465 mm |

| Power | AC 220V 50Hz |

Applications of the Board Smoothness Tester

The Board Smoothness Tester is essential for industries that require precise control over the quality of paper and board surfaces, including:

- Packaging Industry: For testing the smoothness of materials used in packaging, such as cardboard, corrugated paper, and flexible packaging.

- Food and Beverage Packaging: To ensure the smoothness of materials that directly impact packaging performance, such as labels, cartons, and pouches.

- Pharmaceutical Industry: To verify the smoothness of paper and board used for pharmaceutical packaging, which is crucial for ensuring the integrity and ease of packaging process.

- Paper Manufacturers: For quality control in the production of paper and board, ensuring products meet industry standards for smoothness.

- Printing Industry: To test the smoothness of substrates used in printing applications, which directly impacts print quality.

Why Choose the Board Smoothness Tester?

- Accurate & Reliable: With its precise measurements, the Board Smoothness Tester provides highly accurate results that you can rely on for critical quality control.

- Easy to Use: The user-friendly design ensures that even new users can quickly get up to speed with the testing process, minimizing the learning curve.

- Compliance with Global Standards: Meeting ISO 527, DIN 53107, TAPPI T-479, and GB/T 456 standards, this tester is suitable for use in laboratories worldwide.

- Durable and Long-Lasting: Built with high-quality materials, the Board Smoothness Tester is designed for long-term use, providing consistent performance over time.