Butyl Rubber Stopper Puncture Testing Machine Tensile Tester For Medical Plastic Packaging Material Puncture Strength

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | 500N (or As Required) | Stroke | 200mm (without Clamp) |

|---|---|---|---|

| Test Speed | 1~500mm/min | Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. | Control | PLC And Human Machine Interface |

| Output | Screen, Microprinter, RS232(optional) | Power | 110~220V |

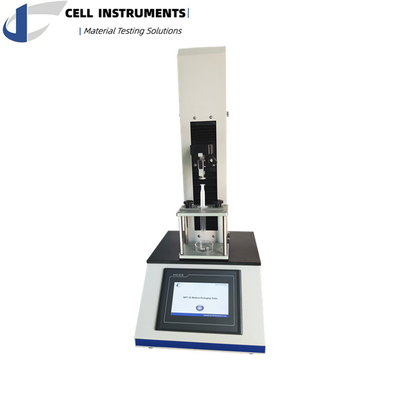

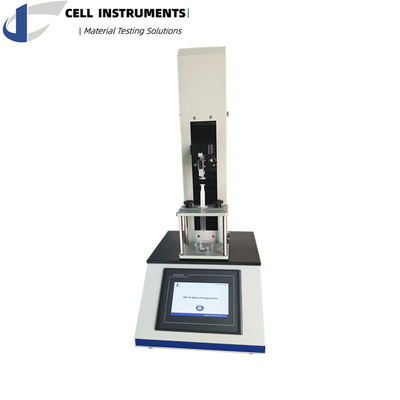

Butyl Rubber Stopper Puncture Testing Machinea Tensile Tester For Medical Plastic Packaging Material Puncture Strength

![]()

Introducing the MPT-01 Medical Packaging Tester – your indispensable solution for evaluating mechanical properties in medical packaging materials. Developed by Cell Instruments, this advanced tester is meticulously designed to ensure the quality, durability, and compliance of packaging materials used in the medical industry.

Advantages of MPT-01 Medical Packaging Tester

Precision and Stability

Experience industrial-level precision and stability with PLC control and a precision ball lead screw mechanism. The HMI touch screen interface enhances user-friendliness while guaranteeing consistent speed and displacement control.

Versatility in Testing

With multiple fixtures available for pulling and compression tests, the MPT-01 accommodates various packaging materials including polymers, bags, ampoules, rubber stoppers, syringes, and needles.

Adjustable Test Speed

Tailor the test speed to meet specific material and application requirements, enhancing adaptability to diverse testing scenarios.

Dual Movement Direction

Conduct tests in both forward and reverse directions for comprehensive assessments of packaging materials.

Safety and Automation Features

Equipped with limit protection and automatic returning mechanisms, ensuring safety against overloading and facilitating the unit's automatic return to its initial position after testing

Data Documentation

Conveniently document test results with the included microprinter, ensuring accurate record-keeping for analysis purposes.

Professional Software Integration

Connect the MPT-01 to a computer via the optional RS232 port for seamless integration with professional software, expanding its capabilities for enhanced data analysis and management.

Why Choose MPT-01 Medical Packaging Tester?

![]()

Regulatory Compliance

Assists in complying with stringent regulatory standards, ensuring packaging materials meet necessary requirements for regulatory approval.

Quality Control

Facilitates quality control processes, verifying packaging materials' adherence to standards and their ability to withstand transportation and storage challenges.

Product Development

Aids in assessing the suitability of packaging options and materials during product development, enabling informed decisions.

Quality Assurance

Identifies defects or weaknesses in packaging materials early, reducing the risk of product recalls and ensuring patient safety.

Main Parameter

| Test Range | 500N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |

Application

![]()

- Testing Capabilities: Excelling in various tests such as tensile testing, compression testing, tear testing, and more.

- Versatility: Accommodates different packaging materials and products efficiently.

- Quality Control: Ensures packaging materials meet required quality standards.

- Compliance: Assists in meeting regulatory requirements, avoiding regulatory issues.

- Product Development: Provides valuable insights for informed decisions during product development.

- Quality Assurance: Crucial for early detection of defects, enhancing patient safety.

Technical Features

- PLC Controlled Unit: Ensures stability and reliability for demanding testing applications.

- HMI Touch Screen Operation: Facilitates user-friendly operation and control of the testing process.

![]()