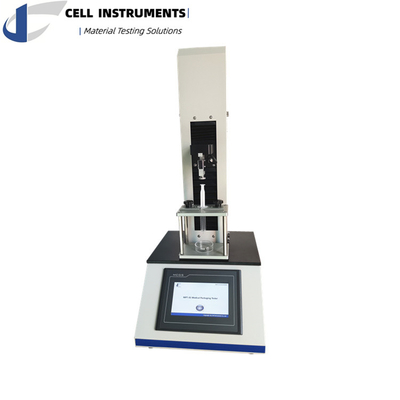

Force Tester About Aluminum Plastic Combination Cover Open Tensile Tester For Medicinal Vial Bottle Lab Quality Testing

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | 500N (or As Required) | Stroke | 200mm (without Clamp) |

|---|---|---|---|

| Test Speed | 1~500mm/min | Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. | Control | PLC And Human Machine Interface |

| Output | Screen, Microprinter, RS232(optional) | Power | 110~220V |

Precision Medical Packaging Tester for Tensile Strength Evaluation

Introduction of MPT-01 Medical Packaging Tester

The MPT-01 Medical Packaging Tester stands as a pinnacle of precision and reliability in the evaluation of mechanical properties inherent in medical packaging materials. Developed by Cell Instruments, this state-of-the-art instrument is meticulously crafted to meet the stringent demands of the medical industry. From impact to thickness, tensile to sealing, this versatile tester ensures packaging materials adhere to rigorous industry standards.

Advantages of MPT-01 Medical Packaging Tester

![]()

Experience precision and stability with our PLC-controlled MPT-01 Medical Packaging Tester. Featuring a user-friendly HMI touch screen interface and a precision ball lead screw mechanism, this instrument guarantees consistent performance across various tests, including aluminum plastic combination cover open force testing and tensile strength evaluation.

Why Choose the MPT-01 Medical Packaging Tester?

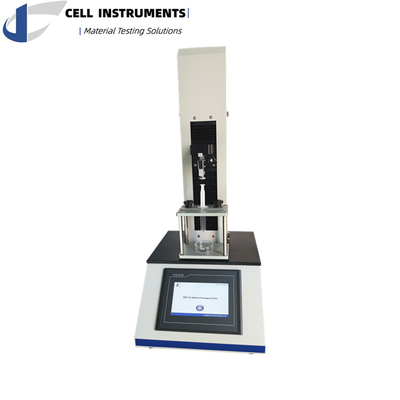

Ensure regulatory compliance and product integrity with the MPT-01 Medical Packaging Tester. From regulatory compliance to quality control, product development to quality assurance, this instrument offers unparalleled versatility and reliability. Conduct a wide range of tests on different packaging configurations, including polymers, bags, ampoules, rubber stoppers, syringes, and needles.

Application of MPT-01 Medical Packaging Tester

![]()

Testing Capabilities

Conduct comprehensive tests, including tensile testing, compression testing, tear testing, and opening force testing, to evaluate the mechanical properties of medical packaging materials.

Versatility

Accommodate diverse packaging materials and products with ease, ensuring efficient testing across various applications.

Quality Control

Guarantee the robustness of medical packaging materials, contributing to the safety and integrity of medical products.

Compliance

Meet regulatory standards set by organizations like the FDA, ensuring market approval and regulatory compliance of medical products.

Product Development

Make informed decisions about packaging choices during the product development phase, enhancing the success of initiatives.

Quality Assurance

Early detection of defects or weaknesses in packaging materials reduces the risk of product recalls and ensures patient safety.

Technical Features

- PLC Controlled Unit: Experience stability and reliability in performance with our programmable logic controller (PLC) controlled unit, ideal for demanding testing applications in the medical industry.

- HMI Touch Screen Operation: Enjoy seamless control and monitoring of the testing process with our human-machine interface (HMI) touch screen, ensuring user-friendly operation.

Main Parameter

| Test Range | 500N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |