Medicine Inner Packaging Material Best Tensile Testing Machine Supplier Tear Strength Testing For Medical Packaging

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Range | 500N (or As Required) | Stroke | 200mm (without Clamp) |

|---|---|---|---|

| Test Speed | 1~500mm/min | Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. | Control | PLC And Human Machine Interface |

| Output | Screen, Microprinter, RS232(optional) | Power | 110~220V |

Medicine Inner Packaging Material Best Tensile Testing Machine Supplier Tear Strength Testing For Medical Packaging

![]()

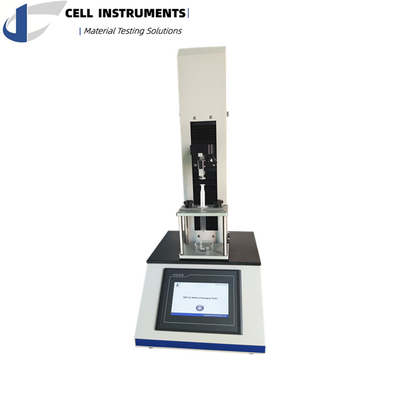

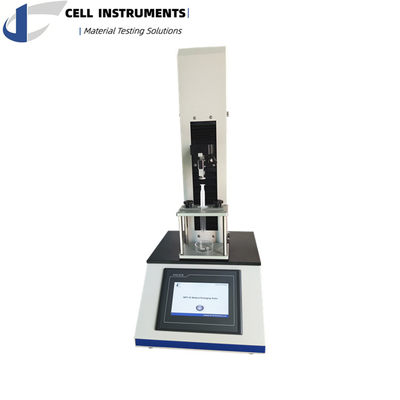

Optimized Product Description: MPT-01 Medical Packaging Tester

Introduction to the MPT-01 Medical Packaging Tester

The MPT-01 Medical Packaging Tester, developed by Cell Instruments, is an advanced and specialized instrument for evaluating the mechanical properties of various packaging materials in the medical industry. This state-of-the-art medical packaging tester performs a range of critical tests to ensure the quality, durability, and compliance of packaging materials with stringent industry standards.

Key Advantages of the MPT-01 Medical Packaging Tester

The MPT-01 Medical Packaging Tester offers numerous advantages, making it an indispensable tool for quality control and research in the medical device and pharmaceutical packaging industries. Key advantages include:

-

Precision and Stability

- Industrial-Level PLC Control: Ensures stable and reliable performance.

- HMI Touch Screen Interface: Facilitates user-friendly operation.

- Precision Ball Lead Screw Mechanism: Guarantees consistent speed and displacement control.

-

Versatility in Testing

- Multiple Fixtures: Accommodates various packaging materials, including polymers, bags, ampoules, rubber stoppers, syringes, and needles.

- Adaptability: Allows manufacturers to conduct a wide range of tests on different packaging configurations.

-

Adjustable Test Speed

- Flexibility: Meets the specific testing requirements of different materials and applications.

- Enhanced Adaptability: Suitable for diverse testing scenarios.

-

Dual Movement Direction

- Comprehensive Testing: Supports tests in both forward and reverse directions, ensuring thorough assessments of packaging materials.

-

Safety and Automation Features

- Limit Protection and Automatic Returning: Safeguards against overloading and facilitates automatic return to the initial position after testing.

-

Data Documentation

- Microprinter: Enables convenient data documentation and reporting, ensuring accurate recording and easy access for analysis.

-

Professional Software Integration

- RS232 Port Connectivity: Allows seamless integration with professional software for enhanced data analysis and management.

Why You Need the MPT-01 Medical Packaging Tester

In the medical device and pharmaceutical industries, ensuring the quality and integrity of packaging materials is paramount. The MPT-01 Medical Packaging Tester is a vital tool for manufacturers and researchers in these industries for several reasons:

-

Regulatory Compliance

- FDA Standards: Assists companies in complying with stringent regulatory standards, ensuring that packaging materials meet the necessary requirements.

-

Quality Control

- Safety and Sterility: Facilitates quality control processes, verifying that packaging materials meet required standards and withstand the challenges of transportation and storage.

-

Product Development

- Packaging Options Assessment: Aids in assessing the suitability of different packaging options and materials during the product development phase.

-

Quality Assurance

- Early Defect Detection: Helps identify defects or weaknesses in packaging materials early in the production process, reducing the risk of product recalls and ensuring patient safety.

Purpose of the MPT-01 Medical Packaging Tester

The primary purpose of the MPT-01 Medical Packaging Tester is to assess the mechanical properties of packaging materials used in the medical industry through a variety of force-related tests, including:

- Tensile Testing: Measuring the material's strength when pulled.

- Compression Testing: Assessing resistance to crushing or deformation.

- Tear Testing: Determining the material's tear resistance.

- Opening Force Testing: Evaluating the ease of opening packaging.

- Penetration Testing: Assessing puncture resistance.

- Breaking Strength Testing: Evaluating overall breaking strength.

- Pull Testing: Conducting tests on various medical packaging materials.

![]()

The adaptable fixtures provided with the MPT-01 allow for testing a diverse range of medical packaging materials, ensuring their quality, durability, and compliance with industry standards and regulatory requirements.

Applications of the MPT-01 Medical Packaging Tester

-

Testing Capabilities

- Wide Range of Tests: Excels in tensile testing, compression testing, tear testing, opening force testing, penetration testing, breaking strength testing, and pull testing.

-

Versatility

- Multiple Fixtures: Easily interchangeable fixtures and accessories accommodate different types of packaging materials and products.

-

Quality Control

- Robustness Verification: Provides accurate and reliable test results, verifying the robustness of medical packaging materials.

-

Compliance

- Regulatory Standards: Assists companies in ensuring that packaging materials and designs meet stringent regulatory requirements.

-

Product Development

- Informed Decisions: Enables manufacturers to make informed decisions about packaging choices during product development.

-

Quality Assurance

- Proactive Approach: Early detection of defects or weaknesses reduces the risk of product recalls and ensures that manufactured medical products meet required quality standards.

![]()

Technical Features of the MPT-01 Medical Packaging Tester

-

PLC Controlled Unit

- Industrial Stability: Programmable logic controller ensures stability and reliability in performance.

-

HMI Touch Screen Operation

- User-Friendly Interface: Facilitates seamless control and monitoring of the testing process.

-

Precision Ball Lead Screw Mechanism

- Consistent Control: Guarantees consistent speed and displacement control, enhancing test accuracy.

-

Microprinter for Data Documentation

- Accurate Recording: Ensures accurate recording and easy access to test results for analysis.

-

RS232 Port for Professional Software Integration

- Enhanced Capabilities: Allows seamless integration with professional software for advanced data analysis and management.

By offering precision, versatility, and advanced features, the MPT-01 serves as a comprehensive solution for manufacturers and researchers involved in the development, production, and quality assurance of medical devices and pharmaceutical products.

Main Parameter

| MPT-01 Medical Packaging Tester | |

| Test Range | 500N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |

![]()