Motorized Closure Torque Tester ASTM D2063 Automatic Torque Testing Machine Glass Bottle Lid Torque Tester

| Test Range | 10 Nm (or As Required) | Accuracy | 1% FS |

|---|---|---|---|

| Resolution | 0.001 Nm | Clamp Range | Φ5mm~φ80mm For Cap Φ5mm~φ170mm For Bottle |

| Power | AC 110~220V |

Motorized Closure Torque Tester ASTM D2063 Automatic Torque Testing Machine Glass Bottle Lid Torque Tester

![]()

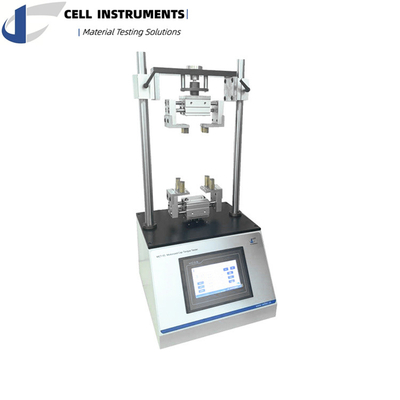

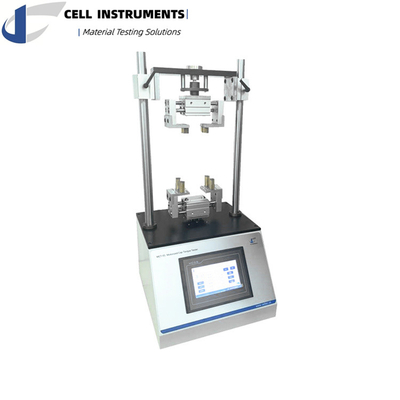

The MCT-01 Motorized Closure Torque Tester from Cell Instruments is an advanced, motorized testing device specifically designed to precisely measure the opening and closing forces of caps and closures. This instrument ensures accurate measurement of torque, critical for quality control across industries like packaging, food, pharmaceuticals, and beverage. Meeting industry standards, including ASTM D2063, this Closure Torque Tester provides reliable testing for a wide range of closure types, including glass bottles, plastic containers, and child-resistant caps.

Equipped with a high-tech PLC (Programmable Logic Controller) system and a sophisticated HMI (Human-Machine Interface) touchscreen, the MCT-01 Closure Torque Tester sets new benchmarks in ease of use and testing accuracy. By automating cap torque measurements, this tester enhances testing efficiency and consistency, making it an indispensable tool for manufacturers aiming to maintain high quality and safety standards.

Key Features of MCT-01 Motorized Closure Torque Tester

-

Precision PLC Control and User-Friendly HMI Touchscreen

The MCT-01 is driven by a robust PLC control unit combined with an HMI touchscreen, allowing operators to effortlessly set parameters, view results, and operate the device with minimal training. This intuitive control setup brings unparalleled accuracy to closure torque testing. -

Automatic Clamping and Rotation for Realistic Testing

The Closure Torque Tester incorporates automated clamping and rotation mechanisms, replicating real-world production line conditions. This feature makes it ideal for testing a variety of closure systems under conditions that closely resemble actual use. -

Dual Pneumatic Clamping for Enhanced Stability

The tester’s upper and lower dual pneumatic clamping system holds caps securely, ensuring that torque measurements are accurate and consistent across tests. This feature is especially valuable for fragile or unique cap designs that require delicate handling during testing. -

Multi-Unit Display for Flexible Measurements

Measurement units are customizable, with options like Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m, catering to international users and enhancing flexibility for diverse testing needs. -

Auto-Zeroing and Overload Protection

To prevent errors and protect the tester, the MCT-01 includes overload protection and an auto-zeroing function, maintaining reliability and extending the device’s lifespan. -

Built-in Micro Printer and RS232 Connectivity

For documentation and data transfer, the tester features a built-in micro printer and an RS232 port, with optional computer software for detailed analysis. This setup enables users to capture, store, and analyze torque data effectively.

Applications of MCT-01 Motorized Closure Torque Tester

The MCT-01 Closure Torque Tester has broad applications across industries where consistent closure performance is essential. Typical uses include:

- Packaging Industry: Ensures caps remain secure throughout the supply chain.

- Food and Beverage: Validates closure torque on glass and plastic bottles, helping to maintain product freshness and consumer safety.

- Pharmaceuticals: Confirms child-resistant caps meet safety standards, ensuring only adults can open medications.

- Cosmetics and Toiletries: Guarantees proper torque in screw-on caps, protecting product integrity and minimizing leakages.

How the MCT-01 Motorized Closure Torque Tester Supports Quality Control

The Closure Torque Tester plays a critical role in quality control by measuring the torque required to open and lock closures. This testing capability assists manufacturers in:

- Ensuring Product Integrity: Accurate measurement of torque prevents premature cap failure during shipping or use.

- Validating Safety Standards: Child-resistant caps and tamper-evident closures must adhere to strict torque specifications for consumer safety.

- Improving Production Consistency: Torque testing helps optimize the manufacturing process, maintaining consistency across production batches.

- Meeting Industry Compliance: The MCT-01 adheres to key testing standards such as ASTM D2063, providing confidence that closures meet regulatory requirements.

Technical Specifications of the MCT-01 Motorized Closure Torque Tester

| Test Range | 10 Nm (or as required) |

| Accuracy | 1% FS |

| Resolution | 0.001 Nm |

| Clamp Range | Φ5mm~φ80mm for cap Φ5mm~φ170mm for bottle |

| Power | AC 110~220V |

Why Choose the MCT-01 Motorized Closure Torque Tester?

The MCT-01 Motorized Closure Torque Tester is a vital asset for manufacturers seeking to enhance product safety and quality. By measuring the precise torque needed for closures, it offers an efficient, reliable solution for industries where sealing performance is paramount.

- Accuracy and Reliability: Built to provide accurate results with minimal error, it reduces testing time and minimizes product waste.

- Advanced Automation: Automated clamping and rotation save labor and improve testing consistency, reflecting actual production conditions.

- User-Friendly Design: The HMI touchscreen, along with the automated features, provides a seamless user experience, even for operators with minimal training.

![]()