Inclined Plane Coefficient Of Friction Tester Static COF Tester Slip Surface COF Tester ASTM D4918, ASTM D202

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Power | 110~220V | Usage | Plastic Testing Machine |

|---|---|---|---|

| Standards | ASTM D 4918, ASTM D 202, And TAPPI T 815 | COF | Static COF Measure |

Inclined Plane Coefficient Of Friction Tester Static COF Tester Slip Surface COF Tester ASTM D4918, ASTM D202

![]()

Introduction to the Inclined Plane Coefficient Of Friction Tester

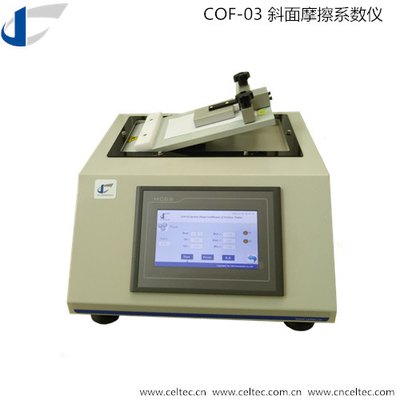

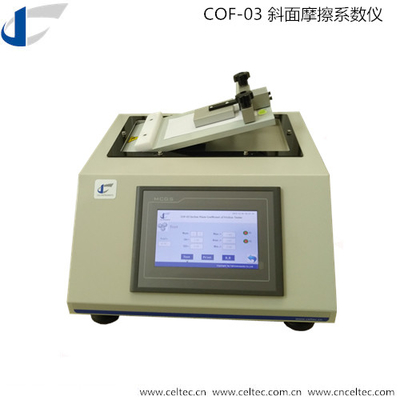

The Inclined Plane Coefficient Of Friction Tester (COF-03) is a precision testing instrument used to measure the static coefficient of friction (COF) of various materials in accordance with international standards. Designed for laboratory use, this device helps businesses in industries such as packaging, food, pharmaceuticals, and more, to assess the frictional properties of materials. The tester employs a variable inclined plane and sliding block mechanism, ensuring highly accurate results in the determination of the frictional properties of different surfaces.

This instrument is particularly useful for quality assurance in industries that require precise testing of material performance under different conditions. Whether you're testing packaging materials, food wrappers, medical packaging, or other materials, the Inclined Plane Coefficient Of Friction Tester provides reliable data to ensure product safety and performance.

Key Features of the Inclined Plane Coefficient Of Friction Tester

- Advanced Control System: The Inclined Plane Coefficient Of Friction Tester operates with a PLC control system and a user-friendly HMI touch screen, allowing for easy operation and real-time monitoring of test results.

- Real-Time Data Display: This tester displays the maximum, minimum, average, and standard deviation of test results, giving you comprehensive insight into your material's performance.

- Multiple International Standards Compliance: The device meets various international standards, including ASTM D 4918, ASTM D 202, and TAPPI T 815, making it ideal for global testing requirements.

- Accurate Angle and COF Measurements: The inclined plane angle can be adjusted between 0° to 60° with an accuracy of 0.01°. The static coefficient of friction (COF) is calculated as the tangent of the angle at which the sample block begins to slide.

- Efficient Testing Mechanism: The inclined plane is raised at a rate of 1.5±0.5° per second by an electric motor, providing a smooth and precise measurement of the static COF.

- Microprint Feature: For easy result documentation, the Inclined Plane Coefficient Of Friction Tester offers a microprint function, allowing you to print out test results quickly and efficiently.

- Optional Software and Connectivity: The instrument comes with RS232 connectivity and optional professional software for advanced data analysis and management, enhancing your testing experience.

- Adjustable Sled Weights: The tester offers a variety of sled weights (200g, 235g, or 1300g), ensuring versatility in testing different types of materials.

Technical Specifications of the Inclined Plane Coefficient Of Friction Tester

| Angle range | 0° ~ 60° |

| Accuracy | 0.01° |

| Stroke | 0.1°/s ~ 10.0°/s |

| Sled | 200g, 235g, or 1300g(choose one or others) |

Applications of the Inclined Plane Coefficient Of Friction Tester

The Inclined Plane Coefficient Of Friction Tester is essential for industries where material friction plays a critical role in product functionality. Key applications include:

- Packaging Industry: Test the frictional properties of films, foils, and other materials used in food, pharmaceutical, and consumer product packaging. Ensuring proper friction is crucial for packaging integrity and ease of handling during the manufacturing and distribution process.

- Food Industry: Assess the friction of materials used for food packaging, particularly those that interact with sealing machines or require specific slip characteristics to maintain freshness and shelf life.

- Medical Packaging: In the medical industry, packaging materials need to meet high standards for friction, ensuring ease of handling while preventing seal failure.

- Consumer Goods: Evaluate friction properties of materials used in various consumer products, such as labels, textiles, and more, to ensure performance meets safety and quality standards.

- Research and Development: The Inclined Plane Coefficient Of Friction Tester is an indispensable tool for R&D departments, helping to develop new materials with desired frictional properties for a variety of applications.

Standards Compliance

The Inclined Plane Coefficient Of Friction Tester adheres to the following standards:

- ASTM D 4918: Standard Test Method for Static Coefficient of Friction of Plastic Film and Sheeting

- ASTM D 202: Standard Test Method for Coefficient of Friction of Plastic Films and Sheeting

- TAPPI T 815: Test Method for Friction of Paper and Paperboard

These industry standards ensure that the tester provides accurate, reliable results that meet global testing and certification requirements.

Why Choose the Inclined Plane Coefficient Of Friction Tester?

- Unmatched Accuracy: The Inclined Plane Coefficient Of Friction Tester provides highly accurate measurements of static friction, ensuring precise results for critical material testing.

- Easy to Use: With an intuitive touch screen interface and PLC control system, the tester is easy to operate, even for users without extensive technical backgrounds.

- Industry-Compliant: The device meets multiple international standards, ensuring it can be used across various industries and regions for regulatory compliance.

- Customizable Testing: With adjustable sled weights and an extensive angle range, this tester is highly versatile, allowing for a wide range of materials to be tested under different conditions.

- Efficient Data Management: The option to print results and integrate with professional software for data analysis makes this tester an invaluable tool for high-volume testing environments.

![]()