Thermoplastic Surface Hot Tack Tester

| Power | Electronic | Usage | Plastic Testing Machine |

|---|

Thermoplastic Surface Hot Tack Tester

The Thermoplastic Surface Hot Tack Tester is an essential laboratory instrument designed to measure the strength of heat seals formed between thermoplastic surfaces of flexible webs. This tester assesses the hot tack strength immediately after a seal has been made and before it cools to ambient temperature. The ability to accurately measure the strength of these seals is critical for ensuring the quality and reliability of packaging materials, especially in industries such as packaging, food, pharmaceuticals, and beverages.

This innovative tester is widely used in testing laboratories where quick and accurate data on seal strength is crucial for evaluating the performance of thermoplastic materials under various conditions. By providing a precise measurement of the force required to separate heat-sealed surfaces, the Thermoplastic Surface Hot Tack Tester helps manufacturers and researchers optimize their sealing processes and improve product packaging performance.

Features and Benefits of the Thermoplastic Surface Hot Tack Tester

-

Precision Measurement: The Thermoplastic Surface Hot Tack Tester is equipped with advanced technology to measure the hot tack strength of heat seals with high accuracy. The instrument applies a controlled amount of force and measures the strength of the bond between thermoplastic surfaces immediately after the sealing process.

-

Flexible Sealing Range: This tester provides an adjustable sealing temperature range from ambient temperature up to 250°C, enabling it to accommodate a variety of thermoplastic materials used in packaging and other industries.

-

Adjustable Heat Seal and Hot Tack Dwell Times: The tester allows users to set the heat seal dwell time and hot tack dwell time from 0.1 seconds to 9999 seconds, offering flexibility for testing a wide range of materials and sealing conditions. This feature ensures that accurate measurements are obtained under different sealing speeds and temperatures.

-

Precision Control: With an accuracy of ±0.2°C in temperature control and load measurement resolution of 0.01N, the Thermoplastic Surface Hot Tack Tester ensures consistent and reliable results. This level of precision is critical for industries where small variations in seal strength can lead to significant product defects or failures.

-

Customizable Load Cell Options: The tester is equipped with a standard 200N load cell, with optional load cells available in 30N, 50N, 100N, and 500N, allowing users to tailor the tester to their specific needs and material types.

-

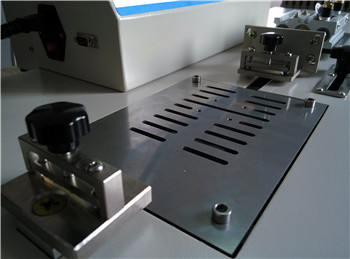

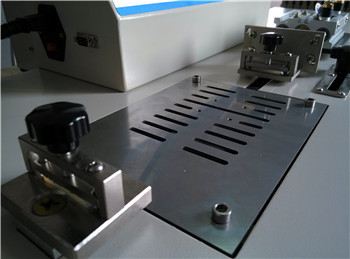

Teflon-Coated Sealing Jaws: The instrument features 50mm x 10mm Teflon-coated sealing jaws, which help to prevent sticking or contamination during the testing process, ensuring clean and reliable results every time.

-

Double Heating Sealing Jaws: The double heating mechanism ensures uniform temperature distribution across the sealing jaws, providing consistent sealing quality and accurate hot tack strength measurements.

Principle of Operation

The Thermoplastic Surface Hot Tack Tester operates by automatically heat-sealing a specimen between its Teflon-coated jaws. Immediately after the seal is formed, the tester measures the strength of the hot seal at a precisely timed interval after the sealing cycle ends. This ensures that the hot tack strength is determined while the seal is still in a molten state, providing valuable insights into the immediate performance of the thermoplastic material before it fully cools and solidifies.

By offering accurate hot tack measurements, this tester enables manufacturers to identify the best sealing parameters for their materials, helping to improve product quality and reduce production errors.

Technical Specifications

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

Applications of the Thermoplastic Surface Hot Tack Tester

The Thermoplastic Surface Hot Tack Tester is widely used across various industries for testing the strength of heat seals in thermoplastic packaging materials. Its applications include:

-

Packaging: Ensuring reliable seals in food, beverage, and pharmaceutical packaging.

-

Plastic Films and Laminates: Testing the performance of films used in packaging materials.

-

Medical Devices: Validating heat seals for sterile packaging in the medical industry.

-

Flexible Packaging: Assessing the bond strength in flexible materials used for sealing.

Why Choose the Thermoplastic Surface Hot Tack Tester?

The Thermoplastic Surface Hot Tack Tester is an indispensable tool for quality control and product development in industries where packaging integrity is crucial. By accurately measuring hot tack strength, it helps manufacturers optimize their sealing processes, reduce material waste, and enhance the overall quality of their products. Whether you're working with flexible films, medical packaging, or food containers, this tester offers the reliability and precision needed for rigorous testing.

![]()

![]()

![]()

![]()