Breaking Strength Tester Ampul Break Force Tester Universal Tensile Testing Machine test measurement instruments

| Product Name | Ampoule Breaking Tester | Model | BST-01 |

|---|---|---|---|

| Power | 110V~220V | ||

| Highlight | compression,breaking,tensile |

||

Breaking Strength Tester Ampul Break Force Tester Universal Tensile Testing Machine test measurement instruments

| BST-01Ampoule Breaking Force Tester | |

| Test Range | 0~200N (Or as required) |

| Speed | 1~500mm/min |

| Resolution | 0.1N |

| Accuracy | 0.5% F.S. |

| Power | 110~ 220V 50/60Hz |

The Breaking Strength Tester is a state-of-the-art testing instrument designed to measure the breaking force of ampoules and other delicate materials. Specifically developed for industries such as pharmaceuticals, food packaging, and medical supplies, the Breaking Strength Tester ensures the durability, quality, and compliance of materials by providing precise and consistent breaking strength measurements. It is crucial in pharmaceutical applications to maintain both product safety and usability, as ampoules containing drugs need to be easily broken by medical professionals but not accidentally opened.

Whether you are testing ampoules, glass containers, or other sealed packaging, the Breaking Strength Tester is a versatile tool that supports a wide range of industries.

Applications of the Breaking Strength Tester

The Breaking Strength Tester is essential for testing the physical properties of materials such as:

- Pharmaceutical ampoules: Ensuring proper neck strength to prevent accidental breakage while maintaining ease of use for medical professionals.

- Food packaging: Measuring the strength of seals and packaging materials to ensure product integrity and safety.

- Medical devices: Verifying the durability of packaging and materials in medical applications to prevent contamination and ensure patient safety.

- Beverage packaging: Testing the strength of glass bottles and other containers used in the beverage industry.

- Universities and laboratories: Used for research and testing of material properties in academic and research settings.

Key Features of the Breaking Strength Tester

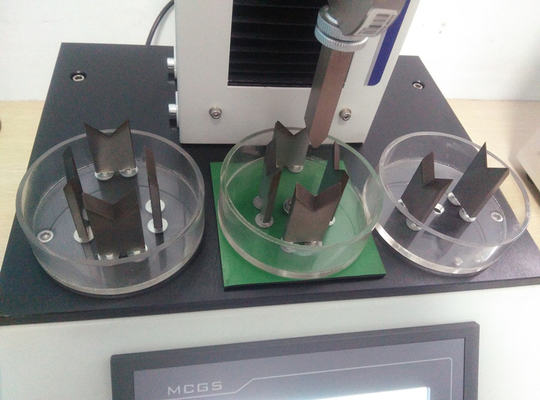

- Intuitive 7-inch TFT Touch Screen: The large, easy-to-use touch screen allows for simple navigation, parameter setting, and real-time test monitoring, enhancing user experience.

- PLC Programmable Logic Controller: The advanced PLC controller ensures precision control of the driving system, optimizing the overall performance of the instrument for accurate and reliable results.

- Precision Ball Screw: This feature guarantees accurate speed and displacement control, critical for consistent test outcomes.

- Adjustable Test Speed: The flexibility to modify the test speed allows the Breaking Strength Tester to adapt to various testing requirements and materials.

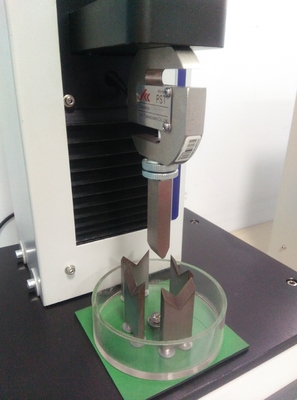

- Tensile and Compression Testing Capabilities: Whether your testing involves pulling (tensile) or compressive forces, this tester is equipped to handle both types of tests with ease.

- Multiple Fixtures Available: The tester supports various fixtures for different types of pulling and compression tests, making it highly versatile across industries.

- Safety Features: A built-in limiting device and automatic return function ensure that the testing process is safe and prevents damage to the instrument or test materials.

Why Choose Our Breaking Strength Tester?

The Breaking Strength Tester offers unparalleled accuracy and control, making it a valuable asset for quality control labs, research institutions, and manufacturing companies. This instrument is designed with the user in mind, offering a combination of cutting-edge technology and user-friendly features.

- Precision Testing: Accurate testing of ampoule neck strength and other material properties is critical to ensuring the safety and performance of your products.

- Enhanced Durability: The tester is constructed from high-quality materials and engineered for long-lasting performance, providing excellent value over time.

- Comprehensive Testing Solutions: With the ability to perform both tensile and compression tests, this tester covers a wide range of material testing needs.

- Industry Compliance: The Breaking Strength Tester complies with GB 2637 and YBB00332002 standards, ensuring that your products meet industry regulations for safety and quality.

Technical Specifications

- Test Range: 0-200N (Standard), adjustable based on testing requirements.

- Test Speed: Standard speed of 10 mm/m for ampoule breaking, with adjustable speeds for other testing scenarios.

- Dimensions: 400mm (L) × 340mm (W) × 800mm (H), compact enough for laboratory use.

- Power Supply: AC 220V, 50Hz for reliable and efficient operation.

Industry Standards

The Breaking Strength Tester adheres to the following industry standards:

- GB 2637: Standard for pharmaceutical ampoules, ensuring safety and consistency in breaking strength.

- YBB00332002: Standard specific to the pharmaceutical industry for glass packaging materials, particularly ampoules.

Benefits of Using the Breaking Strength Tester

- Improved Product Safety: Ensures that ampoules and other containers break with the appropriate force, preventing accidental spills or contamination.

- Cost-Effective: Reduces material waste by identifying weak points in packaging before products reach consumers.

- Enhanced Productivity: The automatic returning function allows for faster testing cycles, increasing throughput in production environments.

- Accurate Results: The combination of advanced sensors and precision engineering delivers highly accurate test data, essential for compliance and quality control.

Typical Use Cases

- Pharmaceutical Manufacturers: Verify the breaking strength of glass ampoules and other medical packaging to ensure safe and consistent performance.

- Food and Beverage Companies: Test the strength of seals, glass containers, and other packaging materials to ensure product integrity.

- Academic Research: Universities and research institutions use the tester to study the physical properties of various materials in controlled environments.

- Medical Device Companies: Ensure that packaging for medical devices meets stringent safety standards.