Material Heat Seal Tester Plastic film heat seal tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Deviation | ±0.2℃ | Sealing Time | 0.1S~9999S |

|---|---|---|---|

| Sealing Pressure | 0.15~0.7 MPa | Seal Jaws | 330*10 Mm L*W |

| Gas Pressure | 0.7 MPa | ||

| Highlight | heat seal,seal,seal strength |

||

![]()

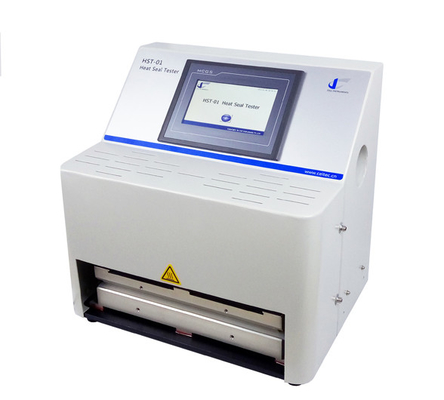

Material Heat Seal Tester: Ensuring Packaging Integrity

A heat seal tester is an essential instrument in the arsenal of industries relying on the integrity of packaging materials, particularly those in the packaging, food, medicine, and beverage sectors. Employed to evaluate the heat sealability of surfaces, sealant layers, and laminates, a heat sealer guarantees the safety and quality of packaged products through precise control of time, temperature, and pressure.

Key Features and Functionality

The HST-01 Heat Seal Tester by Cell Instruments sets the benchmark for stability and precision in laboratory heat seal testing. With its PLC control system and user-friendly HMI touch screen interface, it ensures industrial-level stability and ease of operation. Crafted from aluminum, both the upper and lower components minimize heat loss during sealing, guaranteeing uniform temperature distribution for consistent results.

Equipped with a first-class P.I.D. temperature controller, the HST-01 offers precise temperature regulation, essential for efficient heating and sealing processes. Synchronized seal initiation, facilitated by accurate timing and a proximity sensor, enhances efficiency and reproducibility, while the sealing bar's three-directional guidance ensures uniform pressure distribution across the sample, optimizing seal strength.

Compliance with Industry Standards

Adhering to ASTM F2029-16(2021) standards, the Cell Instruments HST-01 Heat Seal Tester provides reliable and consistent results, meeting the stringent requirements for determining the heat sealability of flexible barrier materials, as measured by seal strength.

Customization Options and Additional Functionalities

Tailored to specific requirements, the HST-01 offers customizable seal jaws in terms of dimensions, shapes, and patterns, providing flexibility for diverse testing needs. Optional features such as the RS 232 COM Port and computer software further enhance its functionality, making it a versatile solution for material physics testing.

Test Process

During testing, a sample is positioned between two parallel heated sealing jaws, allowing the temperature to reach equilibrium. The upper seal jaw, driven by a gas cylinder, applies specific pressure to the sample for a predetermined duration. Upon completion, the upper sealing jaw reverts to its original position, concluding the heat sealability testing process.

Optimize Your Material Physics Testing

Elevate your material physics testing with the HST-01 Heat Seal Tester, a reliable choice for precise and consistent heat sealing in various industries, including packaging, food, medicine, and beverages.

![]()

Main Parameter

| HST-01 | |

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

standard

ASTM F2029, QB/T 2358, YBB 00122003