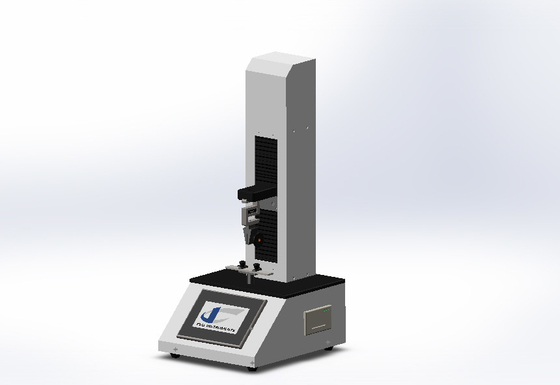

Adhesiveness loop tack tester FINAT Test Method No. 9

| Standard | FINAT Test Method No. 9 | Standard | ASTM D6195 |

|---|---|---|---|

| Test Range | 200N Or Others |

Adhesiveness loop tack tester FINAT Test Method No. 9

![]()

The Loop Tack Tester is an essential testing instrument used for assessing the adhesive properties of various materials like adhesives, tapes, and labels. This advanced device evaluates the tack, adhesiveness, and sticking force of different adhesives, providing precise and reliable results. Whether you're in the packaging, food, pharmaceutical, or beverage industry, the Loop Tack Tester plays a critical role in ensuring the quality and performance of adhesive materials.

What is a Loop Tack Tester?

A Loop Tack Tester is designed to measure the adhesive strength of materials by simulating the initial adhesion of a substrate. This test is particularly useful for testing pressure-sensitive adhesives (PSA) commonly found in tapes, labels, and packaging materials. The loop tack test follows internationally recognized methods such as FINAT Test Method No. 9, PSTC-16, and ASTM D6195, ensuring that the results are consistent and globally acceptable.

Key Features of the Loop Tack Tester

-

7-Inch TFT Touch Screen: The Loop Tack Tester is equipped with an intuitive 7-inch TFT touch screen, making it easy for operators to control and monitor the test process. The human-machine interface (HMI) is designed for user convenience, ensuring that all settings can be adjusted with ease.

-

Stable PLC Control Unit: A high-performance PLC control unit is integrated into the tester to ensure stable performance during operations. This guarantees the accuracy and consistency of test results, making it ideal for high-precision testing in laboratory and industrial environments.

-

Precision Ball Screw for Speed and Displacement Control: The Loop Tack Tester features a precision ball screw that ensures accurate speed and displacement control. This precision is crucial for conducting tests with high reliability, providing accurate adhesion force measurements.

-

Adjustable Test Speed: The tester allows you to adjust the test speed between 1 and 500 mm/m, offering flexibility for various adhesive materials. This feature ensures that different types of adhesives can be tested under optimal conditions.

-

Dual Movement for Enhanced Performance: With dual movement functionality, the Loop Tack Tester allows for both horizontal and vertical movements, enhancing its versatility and ensuring thorough testing of adhesive materials.

-

Limiting Device and Automatic Return: The limiting device prevents overtravel during tests, while the automatic return ensures that the test sample is safely and quickly returned after measurement.

-

Microprinter for Test Data Output: The integrated microprinter provides real-time printouts of test results, allowing for easy documentation and record-keeping. This feature is particularly useful for quality control and compliance with industry standards.

![]()

![]()

Loop Tack Tester Technical Specifications

| Test Range | 200N (or others) |

| Speed Range | 1-500 mm/m |

| Stroke | 200mm |

| Sample Size | 125mm*25mm |

| Power | AC 110~220V, 50/60HZ |

Standard Compliance and Test Methods

The Loop Tack Tester is fully compliant with key industry standards, including:

- FINAT Test Method No. 9 (Loop Tack Measurement): This method is widely used in the adhesive and tape industry for assessing the tack of pressure-sensitive adhesives. It provides a reliable measurement of how well the adhesive adheres to a surface under specific conditions.

- PSTC-16 (Loop Tack Test): A standard method for testing pressure-sensitive adhesives used in tapes, labels, and other packaging materials.

- ASTM D6195: An American standard that outlines the test procedure for determining the loop tack properties of pressure-sensitive adhesives.

These methods ensure that the Loop Tack Tester provides precise and reproducible results, helping businesses in packaging, pharmaceuticals, food, and other industries maintain high-quality adhesive materials.

Applications of the Loop Tack Tester

The Loop Tack Tester is indispensable in various industries, including:

- Packaging Industry: Testing adhesive strength in tapes, labels, and packaging materials.

- Food & Beverage: Ensuring the quality of seals and adhesives used in food packaging.

- Pharmaceuticals: Verifying the adhesive properties of medical tapes and labels.

- Cosmetics: Testing the adhesion of labels on cosmetic packaging.

- Consumer Goods: Ensuring reliable adhesive bonds in everyday products.

By using the Loop Tack Tester, companies can guarantee the quality and reliability of their adhesive products, leading to improved customer satisfaction and compliance with regulatory standards.

Why Choose Our Loop Tack Tester?

Choosing the right Loop Tack Tester is crucial for obtaining accurate results in adhesive testing. Our Loop Tack Tester stands out for its precision, versatility, and ease of use. It is designed for both laboratory and industrial environments, providing consistent performance and reliable data. By utilizing cutting-edge technology, such as the PLC control unit, precision ball screw, and adjustable test speeds, it ensures optimal testing conditions for a wide range of adhesive materials.

Benefits of the Loop Tack Tester

- Accurate and Reliable Results: With advanced technology, the tester ensures precise measurements of adhesive strength and tack, helping to improve the quality of your products.

- Versatility: The tester can accommodate various sample sizes and materials, making it suitable for a wide range of industries.

- Easy Operation: The intuitive touch screen and user-friendly interface simplify operation, reducing the learning curve for new users.

- Compliance with Global Standards: The Loop Tack Tester complies with international test methods, ensuring that your products meet industry standards.

![]()