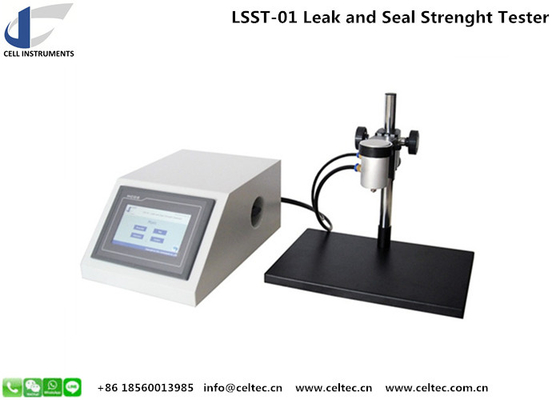

Coffee capsule sealing burst tester Food tray seal burst tester Pressure decay leakage tester

| Standard | ASTM F1140, ASTM F2054, ISO 11607 | Power | 110~220V |

|---|---|---|---|

| Test Mode | Burst, Creep And Creep To Failure. | Pressure Range | 0~600 KPa |

| Sample Width | 300mm (standard) | Inflating Head | Φ4mm |

Coffee capsule sealing burst tester Food tray seal burst tester Pressure decay leakage tester

![]()

The Leak and Seal Strength Tester is a vital tool for industries requiring precise evaluation of packaging integrity. Whether in the realms of packaging for coffee capsules, food trays, or assessing pressure decay in various containers, this instrument ensures uncompromised product protection and quality assurance.

Application

The Leak and Seal Strength Tester plays a pivotal role in assessing package integrity through pressure decay, particularly in scenarios demanding internal pressurization. It serves as an indispensable tool for confirming the sample's capability to withstand pressure, thus guaranteeing the preservation of product freshness and integrity. Our tester facilitates comprehensive seal integrity tests, enabling businesses to explore sustainable packaging options, optimize production line parameters, and adhere to stringent quality control standards.

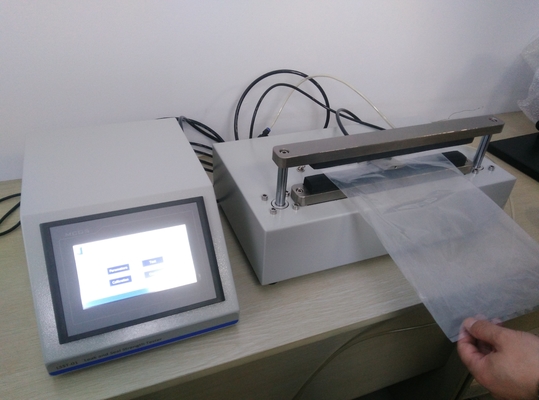

Test Method

![]()

Employing pressure decay as its primary methodology, our Leak and Seal Strength Tester monitors pressure differentials within the sample to detect potential leaks accurately. This technique involves pressurizing the sample to predefined levels and subsequently sealing the air source. Any deviation in pressure signifies a potential flaw in the packaging seal. The instrument offers versatile testing approaches including burst testing, creep testing, and creep-to-failure testing, providing comprehensive insights into package performance.

Technical Features

![]()

Our Leak and Seal Strength Tester boasts an array of technical features designed to ensure industrial-grade reliability and user-friendly operation. With a PLC-controlled unit and intuitive HMI touch screen interface, the instrument guarantees stable performance and seamless operation. Automatic test result logging and statistical analysis streamline data management processes, enhancing efficiency and productivity. Furthermore, the tester's compatibility with various fixture types enables flexible testing of diverse package forms, including open packages, sealed trays, tubes, and more. Customizable sensitivity settings and programmable options empower users to tailor testing parameters according to specific requirements, ensuring accurate and consistent results.

Standard Compliance

The Leak and Seal Strength Tester adheres to industry-standard testing protocols, including ASTM F2054 and ASTM F1140, ensuring compliance with regulatory guidelines and industry best practices.

![]()

![]()

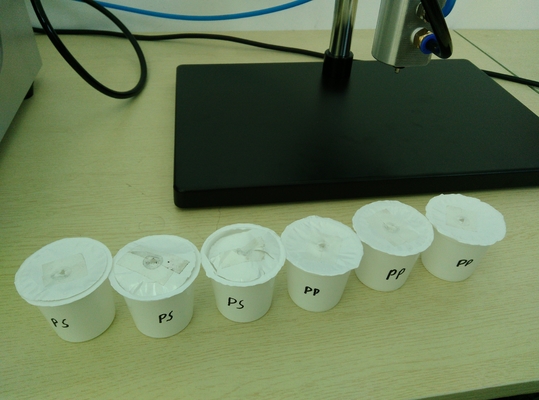

Burst tester for coffee cup seal lid Technical data:

| Pressure Range | 0~600 KPa |

| Beam Width | 300mm(for open package) |

| Inflating Head | Φ4mm (Standard for sealed package) |

| Gas Pressure | 0.4 MPa~0.9 MPa |

| Port Size | Φ6 mm PU hose |

![]()

![]()

Enhance packaging integrity with our Leak and Seal Strength Tester. Ensure product protection and quality assurance through precise pressure decay testing. Compliant with ASTM standards, our tester offers industrial-grade reliability and user-friendly operation.