Best ISO 14616 and DIN 53369 Compliant Shrinkage ratio and shrink force tester Thermal shrink ratio and foce measurement

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Power | AC 220V 50Hz | Product Name | Hot Air Thermal Shrinkage Tester,Thermal Shrinkage Force Tester,FST-01 Medical PVC Sheets Film Free Shrink Tester |

|---|---|---|---|

| Warranty | 12 Months | Usage | Plastic Testing Machine |

| Standard | ISO 11501 | Power Supply | 220V 50Hz |

| Application | Shrinkage And Relaxation Test,composite Film Packaging | Accuracy | ±0.2℃ |

| Temperature Range | RT~ 200°C | Function | Determination Of Heat Shrinking Performance |

Best ISO 14616 and DIN 53369 Compliant Shrinkage ratio and shrink force tester Thermal shrink ratio and foce measurement

![]()

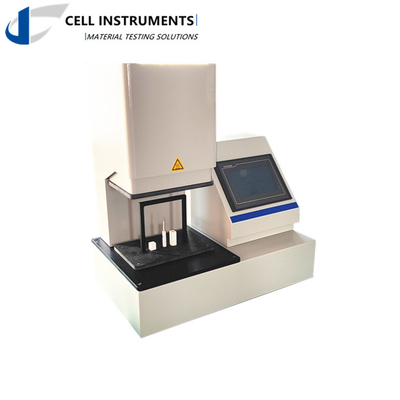

The FSR-01 Film Shrinkage Tester is a precision instrument designed for laboratories and quality control departments to evaluate the shrinkage force and shrinkage ratio of heat shrinkable films. Fully compliant with ISO 14616 and DIN 53369 standards, this tester ensures reliable, repeatable, and accurate measurement results that manufacturers across the packaging, food, beverage, medical, and pharmaceutical industries depend on to guarantee film performance.

As a DIN 53369 shrink force tester, the FSR-01 is engineered for comprehensive shrinkage testing of plastic films. Heat shrinkable packaging films are widely used in shrink-wrapped products, tamper-evident seals, bottle labeling, and protective wraps. Understanding their shrinkage force and shrinkage ratio under controlled thermal conditions is essential for ensuring consistency, durability, and quality in the final application.

Why Choose a DIN 53369 Shrink Force Tester?

The shrinkage behavior of films directly impacts product safety, sealing reliability, and shelf appeal. The DIN 53369 shrink force tester provides critical data on:

-

Shrink Force Measurement – The contraction force generated by films when reheated to their stress-induced temperature.

-

Shrinkage Ratio Analysis – The extent to which the film shrinks, either biaxially or uniaxially, depending on its manufacturing process.

-

Thermal Performance Validation – Ensuring that heat shrinkable films meet packaging requirements under real-world conditions.

Manufacturers who rely on the FSR-01 tester can optimize film formulations, ensure compliance with international standards, and reduce risks associated with packaging failures.

Principle of Operation

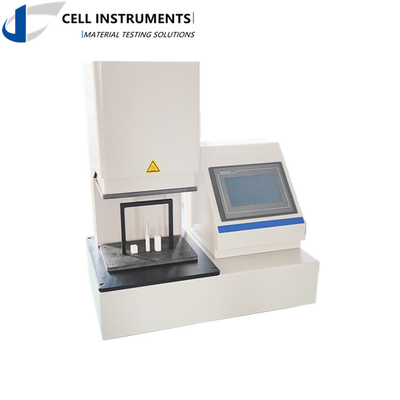

During production, shrink films are stretched and cooled under stress. When reheated, these films contract back toward their original dimensions, generating measurable forces. The FSR-01 DIN 53369 shrink force tester replicates this process with controlled precision:

-

The air oven is pre-heated to the target temperature.

-

Two specimens are mounted—one for shrinkage ratio testing, one for shrink force testing.

-

A probe measures the reference temperature at the sample location.

-

The oven is automatically lowered to cover the sample area.

-

Shrinkage force and shrinkage ratio are continuously recorded in real time.

-

The shrinkage temperature is identified at the peak force value.

-

When force decreases by 15–30%, the oven is raised and testing time is documented.

-

Shrinkage ratio is calculated at the mean time interval.

This systematic method eliminates operator errors and delivers consistent, reproducible data for film evaluation.

Key Features of the FSR-01 DIN 53369 Shrink Force Tester

-

PLC Control System – Provides industrial-grade stability and precise test control.

-

Touchscreen HMI Operation – User-friendly interface with intuitive workflows.

-

Well-Insulated Air Oven – Ensures uniform heating with minimal thermal loss.

-

Automatic Lowering & Lifting System – Reduces handling errors and improves test repeatability.

-

Non-Contact Shrink Ratio Measurement – Prevents distortion and guarantees sample integrity.

-

Real-Time Data Display – Monitors shrinkage force, shrinkage ratio, and temperature simultaneously.

-

Friction & Airflow Interference Elimination – Achieves highly accurate readings by removing external factors.

-

Stable Heating Technology – Delivers consistent thermal conditions throughout the test cycle.

-

High-Resolution Sensors – Equipped with advanced force transducers and thermometers.

-

Data Output & Analysis – Optional RS-232 connectivity with professional software for result export and statistical analysis.

Technical Specifications

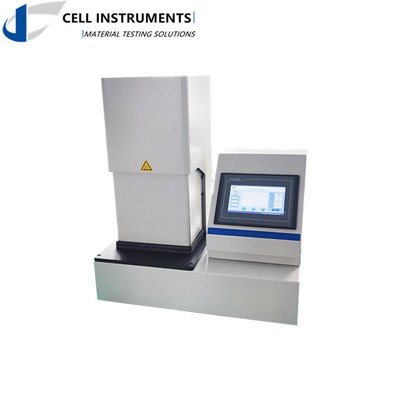

| Parameter | Specification |

|---|---|

| Force Range | 5 N (or as required) |

| Force Accuracy | ±0.5% |

| Force Resolution | 0.001 N |

| Displacement Range | 0.1 – 95 mm |

| Displacement Accuracy | ±0.1 mm |

| Temperature Range | Ambient – 210°C |

| Temperature Accuracy | ±0.5°C |

| No. of Specimens | 2 |

| Sample Size | 110 × 15 mm (L × W) |

| Power Supply | 220V / 50Hz |

Standards Compliance

-

ISO 14616 – Packaging materials: Determination of shrinkage force and shrinkage ratio.

-

DIN 53369 – Testing of plastics: Determination of shrinkage force and shrinkage ratio of films.

By meeting both international standards, the FSR-01 ensures test results are valid for global compliance and universally recognized by material suppliers, converters, and end-users.

Applications Across Industries

The FSR-01 is suitable for testing films used in:

-

Food Packaging – Shrink wraps for meat, dairy, frozen goods, and ready-to-eat meals.

-

Beverage Industry – Bottle shrink labels and tamper-evident seals.

-

Pharmaceutical Packaging – Blister wraps, protective films, and medical device packaging.

-

Industrial Applications – Electrical insulation sleeves, protective wraps, and logistics packaging.

-

Research & Development – Universities, testing institutes, and film manufacturers for new material development.

Advantages for Quality Control

Using the DIN 53369 shrink force tester helps companies achieve:

-

Enhanced Film Quality – Detect weaknesses before production scale-up.

-

Reduced Packaging Failures – Prevent leaks, poor seals, or label deformations.

-

Cost Efficiency – Optimize material usage and avoid product recalls.

-

Compliance Assurance – Easily demonstrate adherence to ISO and DIN standards.

-

Market Competitiveness – Deliver high-performance packaging that meets customer expectations.

Why Choose Cell Instruments?

Cell Instruments specializes in material testing equipment for packaging, medical, food, and industrial applications. With years of expertise, strict compliance with international testing standards, and a focus on precision, the FSR-01 DIN 53369 shrink force tester is the trusted choice for laboratories worldwide. Our instruments are designed for accuracy, durability, and ease of use, ensuring long-term value for every client.

Conclusion

The FSR-01 DIN 53369 shrink force tester is more than just a film testing instrument—it is a vital quality assurance tool. By providing accurate, repeatable measurements of shrinkage force and shrinkage ratio, it empowers manufacturers to improve film performance, meet international compliance requirements, and safeguard end-product integrity.

Whether you are in food, beverage, pharmaceutical, or industrial packaging, the FSR-01 is an indispensable addition to your laboratory equipment.

![]()