Hot Tack Tester HTT-02 ASTM F1921 Hot Tack Method B Polymer Heat Seal And Hot Tack Tester

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Usage | Plastic Testing Machine | Product Name | Hot Tack Tester,Property Test For Plastic Film Hot Tack Tester,Flexible Package Hot Tack Testing Machine HTT- 01,Heat Seal And Hot Tack Tester HTT- 01 Hot Tack Force Tester |

|---|---|---|---|

| Dwell Pressure | 0.15MPa~0.7MPa | Seal Temperature | Room Temperature~250 |

| Dwell Time | 0.1s~9999s | Keyword | Hot Tack Tester,hot Tack Testing Equipment |

Hot Tack Tester HTT-02 ASTM F1921 Hot Tack Method B Polymer Heat Seal And Hot Tack Tester

The Hot Tack Tester HTT-02 is a cutting-edge instrument designed for the precise measurement of the strength of heat seals formed between thermoplastic surfaces immediately after sealing. It is ideal for industries like packaging, food, medical, beverage, and others where heat sealing plays a critical role in product integrity. The HTT-02 Hot Tack Tester ensures reliable, reproducible results that adhere to ASTM F1921 standards, allowing users to assess the strength of heat seals before they cool to room temperature.

As part of the comprehensive testing suite for material physical properties, the HTT-02 Hot Tack Tester is an indispensable tool for manufacturers who need to ensure the quality and durability of their packaging seals. This tester is crucial for evaluating seals that must withstand various external forces, such as those applied during packaging, transportation, and handling.

Key Features of the HTT-02 Hot Tack Tester:

-

Dual Method Testing: The HTT-02 Hot Tack Tester complies with both Method A and Method B of ASTM F1921, offering versatility in testing heat seal strength under different conditions.

-

P.I.D. Temperature Control: Features precise P.I.D. temperature control to ensure that the heat sealing process is consistent, improving the accuracy and reliability of results.

-

Advanced User Interface: The tester comes with a 7-inch HMI touchscreen interface that makes operation intuitive, allowing users to easily adjust test parameters and monitor progress.

-

PLC Control: The HTT-02 Hot Tack Tester is integrated with a PLC (Programmable Logic Controller) for enhanced control over test conditions, ensuring accurate and repeatable results.

-

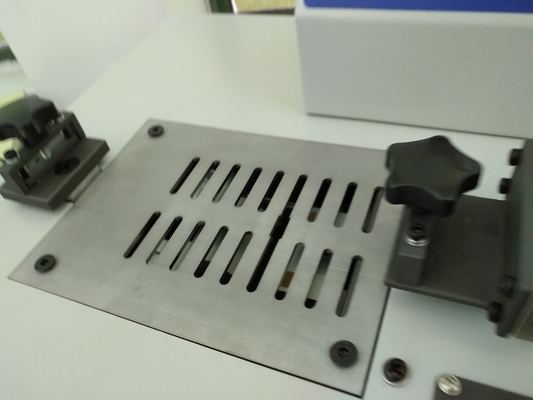

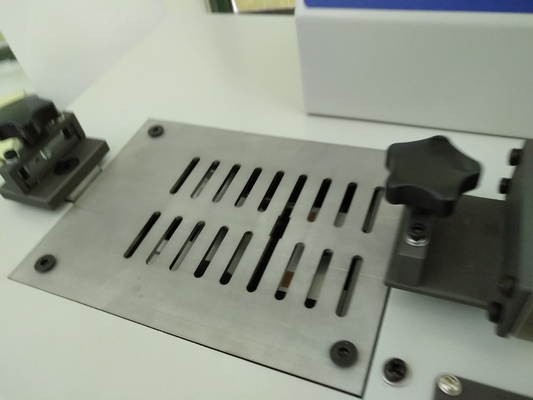

Aluminum Sealing Jaws: The sealing jaws are made from high-quality aluminum and are encapsulated for durability, ensuring longevity and resistance to wear and tear.

-

Auto Zeroing & Overload Protection: The tester includes automatic zeroing and overload protection features, which prevent errors in testing and protect the system from damage.

-

Adjustable Test Speed: The testing speed can be easily adjusted from 200 cm/min to 1200 cm/min, allowing flexibility to meet various testing requirements.

-

Connectivity: The HTT-02 Hot Tack Tester features an RS 232 port for easy integration with other devices, and optional professional software is available for further analysis.

Specifications of the HTT-02 Hot Tack Tester:

| Sealing Temp. | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Dwell Time | 0.1~9999s(Heat Seal ) |

| Dwell Time | 0.1~9999s(Hot Tack ) |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N, etc) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

| Power | 220V, 50 HZ |

Applications of the Hot Tack Tester:

The HTT-02 Hot Tack Tester is primarily used to test the immediate strength of heat seals formed between thermoplastic materials, especially in applications that require quick assessments before cooling. It is perfect for industries where product packaging integrity is essential. The tester is widely used in the following fields:

-

Packaging Industry: Ensures the reliability of heat-sealed packages, particularly for flexible packaging.

-

Food Packaging: Assesses the strength of heat seals in food packaging materials, ensuring that they maintain freshness and security.

-

Medical Packaging: Helps verify the strength of seals in medical device packaging, ensuring compliance with strict safety standards.

-

Beverage Packaging: Ensures the integrity of heat seals in beverage containers, where maintaining freshness and preventing leakage are crucial.

-

Plastic and Polymer Testing: Provides valuable insights into the heat sealing properties of various polymer materials, ensuring optimal performance.

Why Choose the HTT-02 Hot Tack Tester?

-

Reliable and Consistent Results: The HTT-02 Hot Tack Tester provides accurate and reproducible results, essential for quality assurance in manufacturing processes.

-

Versatility: With both Method A and Method B options, it can meet a variety of testing needs, making it suitable for diverse industries and applications.

-

Ease of Use: The user-friendly interface, combined with advanced controls and protection features, ensures that the testing process is efficient and safe.

-

Durability: The HTT-02 Hot Tack Tester is designed to withstand heavy use, with robust components like aluminum sealing jaws and a double heating system for longevity and reliable performance.

Conclusion:

The HTT-02 Hot Tack Tester is an essential instrument for anyone working with thermoplastic materials, especially in industries where heat sealing is critical. Whether you're testing food packaging, medical devices, or beverage containers, the Hot Tack Tester offers the precision and reliability you need to ensure quality and performance. The HTT-02 complies with ASTM F1921 standards and is equipped with advanced features like PLC control, P.I.D. temperature regulation, and adjustable testing speeds, making it the top choice for laboratories and manufacturers alike.

![]()

| Sealing Temperature | Ambient~250℃ |

| Temp Accuracy | ±0.2℃ |

| Heat Seal Dwell Time | 0.1~9999s |

| Hot Tack Dwell Time | 0.1~9999s |

| Sealing Pressure | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Sealing Jaws Heating | Double Heating |

| Load Cell | 200N(Optional:30N50N100N500N) |

| Accuracy | 0.5 F.S. |

| Resolution | 0.01N |

![]()

![]()

![]()