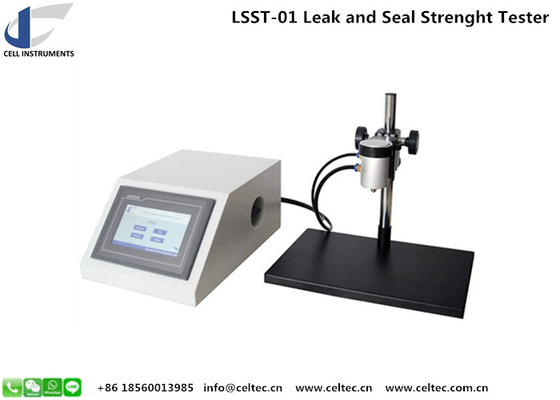

THREE SIDE SEAL PACKAGE BURST TESTER ASTM F2096 INTERNAL PRESSURIZATION BUBBLE TESTING EQUIPMENT

| Standard | Astm F1140 Astm F2096 Astm F2054 | Method | Positive Pressure Internal Pressure Burst |

|---|---|---|---|

| MOQ | 1 Set | Power | 110~220V |

THREE SIDE SEAL PACKAGE BURST TESTER takes the pressure decay internal pressurization method. By checking the maximum burst value, the defects in lid structure, material and sealing technics can be analyzed. It’s ideal sealing integrity checking equipment for sectors like yogurt, milk, cheese, ice cream, water, juice, beverage, coffee, tea, cosmetic, seasoning etc.

![]()

THREE SIDE SEAL PACKAGE BURST TESTER adopts the latest industrial level PLC control unit and color human-machine interface. Operation is direct and convenient. Three tests modes of burst, creep and creep to failure are embedded.

Together with other forms of accessories, it can be applied to other forms of packaging also, like bag, bottle, container, aerosol valve, tube, etc.

THREE SIDE SEAL PACKAGE BURST TESTER standards to follow:

ASTM F1140: Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages

ASTM F2054: Standard Test Method for Burst Testing of Flexible Package Seals Using Internal Air Pressurization within Restraining Plates

F2096-11(2019) Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test) bubble test

THREE SIDE SEAL PACKAGE BURST TESTER Technical data:

| Pressure Range | 0 ~ 600 KPa |

|

Inflating Head |

Φ4mm (customization available) |

|

Gas Pressure |

0.4 MPa~0.9 MPa |

|

Port Size |

Φ6 mm PU hose |

![]()

![]()

![]()