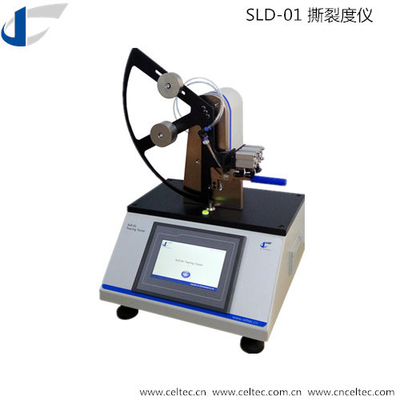

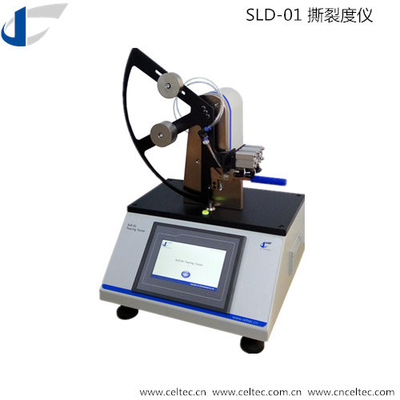

Pendulum Method Propagation Tear Resistance Tester Film And Thin Sheeting Tearing Force Tester Mn And Gf

| Material | Film, Paper, Fabric | General Use | Tearing Strength Or Force Test |

|---|---|---|---|

| Product Name | Elmendorf Tear Tester | Application | Material Tearing Force Tester |

| Packing | Export Plywood Carton |

Pendulum Method Propagation Tear Resistance Tester Film And Thin Sheeting Tearing Force Tester Mn And Gf

Film And Thin Sheeting Tearing Force Tester

High-Precision Instrument for Measuring Tear Resistance in Flexible Materials

The Film And Thin Sheeting Tearing Force Tester is a laboratory-grade testing instrument engineered for accurately determining the tear resistance of flexible films and thin sheet materials. This high-performance tester utilizes the pendulum method to assess tear propagation resistance in materials such as plastic films, paper, textiles, waterproof composites, and other packaging substrates. It is widely used in quality control, R&D, and compliance testing across industries including packaging, food, medicine, beverages, academic research, and material production.

By measuring the energy loss as a pendulum tears through a precut slit in a specimen, the Film And Thin Sheeting Tearing Force Tester provides precise, repeatable, and standards-compliant tear resistance data. This ensures consistent product quality and meets regulatory and customer-specific requirements.

Key Applications

The Film And Thin Sheeting Tearing Force Tester is ideal for testing a variety of thin and flexible materials, including but not limited to:

-

Plastic films (LDPE, HDPE, PET, PP)

-

Thin sheeting and membranes (PVC, PVDC)

-

Laminated packaging films

-

Nonwoven and woven fabrics

-

Kraft paper, cardboard, coated papers

-

Textile samples and medical drapes

-

Waterproof and breathable composite sheets

Its versatility makes it an essential instrument for manufacturers and laboratories focused on material strength, durability, and compliance.

Working Principle

This instrument operates on the pendulum tear test method, also referred to as the Elmendorf tear test. A pendulum arm is lifted and released, tearing the specimen from a precisely precut slit. The energy lost during the tear correlates with the force required to propagate the tear, which is automatically calculated and displayed. This method ensures consistent tear resistance values and supports high-throughput testing.

Advanced Features

-

PLC-Controlled System: Ensures stable, intelligent control of the testing process.

-

User-Friendly Interface: Touchscreen human-machine interface (HMI) for easy operation.

-

Pneumatic Clamping: Provides firm and uniform specimen fixation, reducing human error.

-

Automatic Pendulum Release: Enhances testing consistency and operational safety.

-

Flexible Pendulum Capacity: Multiple pendulum options (200 gf to 6400 gf) for various material strengths.

-

Auto Data Processing: Automatic statistics, test result storage, and report generation.

-

Built-in Microprinter: Instantly print results for documentation and compliance audits.

-

RS232 Data Output Port: For easy connection to PCs and optional software for analysis and archiving.

Compliance With International Standards

The Film And Thin Sheeting Tearing Force Tester complies with global testing standards, ensuring that test results are recognized across the industry:

-

ASTM D1922 – Propagation Tear Resistance of Plastic Film and Thin Sheeting

-

ASTM D1424 – Elmendorf Tear Resistance of Paper

-

ASTM D689 – Tear Resistance of Paper (Paperboard)

-

ISO 6383 – Tear Test for Plastic Films

-

ISO 1974 – Internal Tearing Resistance of Paper

-

GB/T 16578.2-2009

-

GB/T 455 – Paper and Board Tear Resistance

-

TAPPI T414 – Internal Tearing Resistance of Paper

These standards ensure that the data produced by the instrument is reliable, reproducible, and acceptable for global trade, certifications, and compliance testing.

Technical Specifications

| Item | Specification |

|---|---|

| Pendulum Capacity | 200 gf, 400 gf, 800 gf, 1600 gf, 3200 gf, 6400 gf (selectable) |

| Tearing Arm Length | 104 ± 1 mm |

| Initial Tearing Angle | 27.5 ± 0.5° |

| Gas Source Requirement | 0.6 MPa |

| Operation | Semi-automatic with HMI and pneumatic clamp |

| Data Output | Microprinter & RS232 port (optional software) |

Why Choose Our Film And Thin Sheeting Tearing Force Tester?

-

Precision Engineering: Designed for high accuracy and repeatability.

-

Broad Material Compatibility: Suitable for a wide range of films, papers, and fabrics.

-

Flexible Configuration: Customize pendulum weights for different material strengths.

-

Ease of Use: Streamlined interface and automatic functions reduce training time.

-

Durable & Reliable: Industrial-grade components and construction ensure longevity.

-

Data Management: Efficient report generation, storage, and transfer options.

-

Standard Compliance: Aligns with key ASTM, ISO, GB, and TAPPI standards.

Industries Served

The Film And Thin Sheeting Tearing Force Tester supports quality assurance and product development in:

-

Packaging Manufacturing (flexible pouches, laminated films)

-

Pharmaceutical Industry (blister films, medical drapes)

-

Food and Beverage (bottle labels, wrapper integrity)

-

Textile Production (woven/nonwoven fabric strength)

-

Paper and Printing (tear resistance in paperboard)

-

Academic and Research Institutions (material science, packaging R&D)

Typical Use Cases

-

Film Converter testing the tear strength of multi-layer plastic films for packaging.

-

Textile Factory ensuring internal quality standards for woven materials.

-

Label Manufacturer assessing adhesive strength and tear properties of printed materials.

-

University Lab conducting comparative material studies and validating manufacturing consistency.

Customization Options

We offer tailored configurations to meet specific testing requirements. Options include:

-

Custom pendulum capacities

-

Advanced software integration for remote data analysis

-

Multi-language interface support

-

Special clamping fixtures for irregular samples

Contact our team for assistance with customization or to discuss your application needs.

![]()

![]()

![]()

![]()

![]()