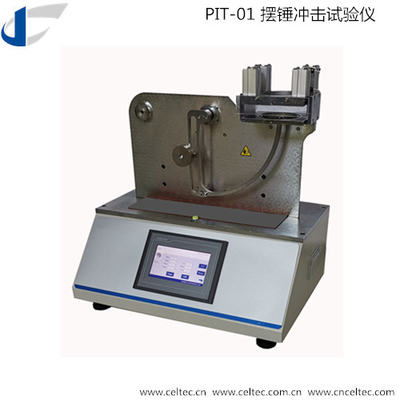

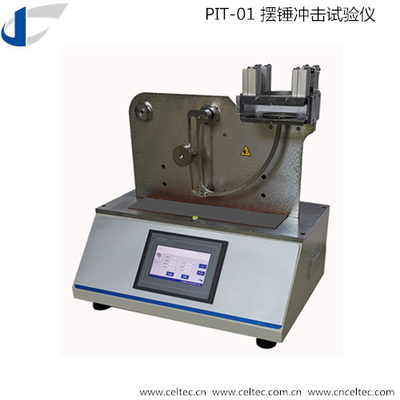

Pendulum Impact Resistance Tester For Plastic Films Impact Loading Pendulum Impact Test Dynamic Ball Burst

| Power | AC110~220V,50/60Hz | Usage | Impact Testing Machine |

|---|---|---|---|

| Product Name | Impact Tester | Warranty | 12 Months |

| Application | Analysis Of Various Kinds Of Materials | Operation | PLC And HMI Touch Screen, Optional Software |

Pendulum Impact Resistance Tester For Plastic Films Impact Loading Pendulum Impact Test Dynamic Ball Burst

Introduction

The Pendulum Impact Resistance Tester is a precision-engineered instrument designed to evaluate the impact resistance of various materials, including plastic films, sheets, composite films, aluminum foils, and paper. By measuring the energy absorbed during impact, this tester provides critical data for quality control and material performance analysis, ensuring compliance with industry standards such as ASTM D3420.

Key Features

-

PLC Control and HMI Touch Screen Operation: Ensures industrial-level stability and user-friendly control for seamless operation.

-

Pneumatic Specimen Clamping and Pendulum Automatic Release: Guarantees consistent and reliable clamping for accurate results, essential for impact resistance testing.

-

Data Auto Statistics and Storage: Automates data collection and analysis, streamlining the reporting process for improved efficiency.

-

Precise Angle Measurement: Utilizes a high-precision encoder to calculate impact energy rapidly and accurately after the test specimen is struck under specific conditions of angle and energy.

-

Support for Customized Microprinter: Facilitates immediate printing of test results for documentation and analysis.

-

RS232 Port and Software (Optional): Allows for advanced data analysis and integration with laboratory information management systems.

Technical Specifications

| Impact Energy | 1 J, 2 J, 3 J |

| Resolution | 0.001 J |

| Impact Head Size | Ф25.4, Ф19, Ф12.7 mm |

| Specimen Clamp | Pneumatic Clamp |

| Clamp Diameter | Ф89 mm, Ф60 mm |

| Gas Supply | 0.6 MPa Φ6 mm PU Tubing |

| Specimen Size | 100*100 mm or Ф100 mm |

| Power Supply | AC 110~220V 50Hz |

Applications

The Pendulum Impact Resistance Tester is suitable for a wide range of applications across various industries:

-

Packaging Industry: Evaluates the impact resistance of flexible packaging materials to ensure product integrity during handling and transportation.

-

Food and Beverage Industry: Tests the durability of packaging films and materials used in food and beverage containers.

-

Pharmaceutical Industry: Assesses the strength and reliability of packaging materials for medicines and medical devices.

-

Educational and Research Institutions: Provides a reliable method for studying material properties and conducting research in material science.

-

Material Manufacturing: Ensures that materials meet required impact resistance standards before being utilized in production.

Compliance with Standards

This tester complies with the ASTM D3420 standard, which provides a means to determine parameters of a material at strain rates closer to some end-use applications than provided by low-speed uniaxial tensile tests.

Advantages

-

High Precision and Accuracy: The tester's advanced detection system ensures accurate test results, offering reliable insights into how materials behave under impact.

-

User-Friendly Operation: The intuitive touchscreen interface allows operators to effortlessly set up parameters and operate the tester, minimizing the risk of errors during operation.

-

Efficient Data Management: Supports real-time monitoring of working status and enables users to save test results upon completion of tests, providing valuable test data for performance analysis and improvement.

-

Versatility: Suitable for testing a variety of materials, including plastic films, composite films, aluminum foils, and paper, making it a versatile tool for multiple industries.