Coefficient Of Friction (COF) And Slip Max Angle Tester Tappi T-815 And ASTM D202 Sliding Blocks

| Power | 110~220V | Usage | Plastic Testing Machine |

|---|---|---|---|

| Standards | ASTM D 4918, ASTM D 202, And TAPPI T 815 | COF | Static COF Measure |

Film Friction Coefficient Tester | High-Precision Static & Kinetic Friction Testing Equipment

Introduction to Film Friction Coefficient Tester

![]()

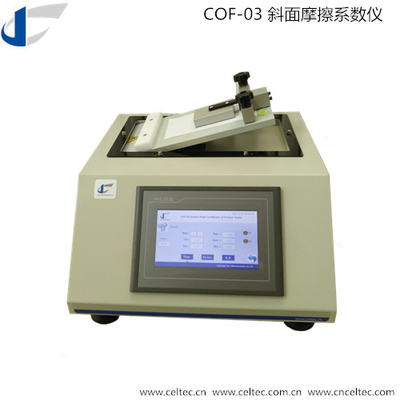

The Film Friction Coefficient Tester is an advanced laboratory instrument designed to accurately measure the static and kinetic coefficients of friction (COF) for a wide range of materials, including plastic films, sheets, rubber, paper, and cardboard. This essential testing equipment plays a critical role in quality control and material performance analysis, ensuring optimal processing and usability of flexible materials in various industries such as packaging, food, pharmaceuticals, printing, and textiles.

By utilizing cutting-edge PLC control technology and a user-friendly touchscreen interface, the Film Friction Coefficient Tester provides precise, reliable, and repeatable friction measurements. The device complies with international testing standards, including ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, making it the ideal choice for laboratories and manufacturing facilities seeking compliance with global industry regulations.

Test Principle of the Film Friction Coefficient Tester

The Film Friction Coefficient Tester operates on a well-defined testing principle that involves measuring the force required for two materials to slide against each other. The test procedure includes:

-

Sample Preparation: Two material samples are prepared—one is fixed to a flat surface, and the other is attached to a sled.

-

Static Friction Measurement: The force required to initiate motion between the two samples is recorded as the static coefficient of friction (COF).

-

Kinetic Friction Measurement: The force required to maintain the sliding motion at a constant speed is recorded as the kinetic coefficient of friction (COF).

-

Data Analysis: The tester provides real-time friction force measurements, allowing users to evaluate material behavior under different conditions.

Technical Features of the Film Friction Coefficient Tester

-

PLC control system for precise automation and enhanced user experience

-

Touchscreen operation for easy configuration and monitoring

-

Real-time display of test data, results, and graphical curves

-

High measurement accuracy with a load cell capacity of 5N and 0.5% F.S. precision

-

Static and kinetic COF testing in a single operation

-

Adjustable sled weight with a default 200g sled (63.5mm × 63.5mm) and customization options

-

Variable stroke and test speed settings: 100mm/min (ISO standard) and 150mm/min (ASTM standard)

-

Compliance with international standards: ASTM D1894, ISO 8295, TAPPI T816, GB 10006

-

RS232 data output and optional professional software for data analysis

-

Built-in microprinter for quick result printing and reporting

Applications of Film Friction Coefficient Tester

The Film Friction Coefficient Tester is widely used across various industries for evaluating the surface characteristics of materials to optimize processing conditions and end-product performance.

-

Plastic Film Industry: Ensures smooth processing in film manufacturing and printing.

-

Packaging Industry: Determines slip properties for flexible packaging materials.

-

Pharmaceutical Industry: Evaluates the friction behavior of medical packaging materials.

-

Textile Industry: Measures the friction of woven and non-woven fabrics.

-

Paper & Printing: Analyzes friction properties of paper, labels, and printed materials.

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Cell | 5 N |

| Accuracy | 0.5% F.S. |

| Stroke | As Required |

| Sled | 200 g (63.5mm × 63.5mm) Customization Available |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Standards | ASTM D1894, ISO 8295, TAPPI T816, GB 10006 |

Why Choose Our Film Friction Coefficient Tester?

-

Highly Accurate & Reliable: Designed for laboratory and industrial applications.

-

User-Friendly Operation: Intuitive touchscreen controls and automated functions.

-

Customizable Testing Options: Adjustable sled weight and stroke length.

-

Global Compliance: Meets international standards for friction testing.

-

Data Analysis & Reporting: Supports real-time data output and printing.

Frequently Asked Questions (FAQs)

Q1: What is the difference between static and kinetic friction?

A1: Static friction is the force required to initiate motion, while kinetic friction is the force needed to maintain motion. The Film Friction Coefficient Tester measures both parameters for precise material analysis.

Q2: Can the tester be used for different materials?

A2: Yes, the tester is suitable for plastic films, paper, textiles, rubber, and coated materials, making it versatile for various industries.

Q3: What standards does this tester comply with?

A3: It complies with ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, ensuring international testing accuracy and reliability.

Q4: How does the touchscreen interface improve testing efficiency?

A4: The touchscreen operation allows users to quickly configure tests, monitor real-time results, and access graphical data analysis.

Q5: Is the tester compatible with external data analysis software?

A5: Yes, the tester offers RS232 output for external software integration and professional data management.

![]()