Kinetic (Moving) And Static (Starting) Resistance Force Tester Cof Measure Astm D1894 Iso 8295

| Usage | Paper Testing Instrument,Textile Testing Instrument,Plastic Testing Machine | Standard | ISO8295,ASTM D1894 |

|---|---|---|---|

| Warranty | 12 Months | Product Name | Packaging Materials Coefficient Of Friction Tester |

| Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester | Power Supply | 110~220V |

| Force Range | 0-5N | Material | Film |

Kinetic (Moving) And Static (Starting) Resistance Force Tester Cof Measure ASTM D1894 ISO 8295

![]()

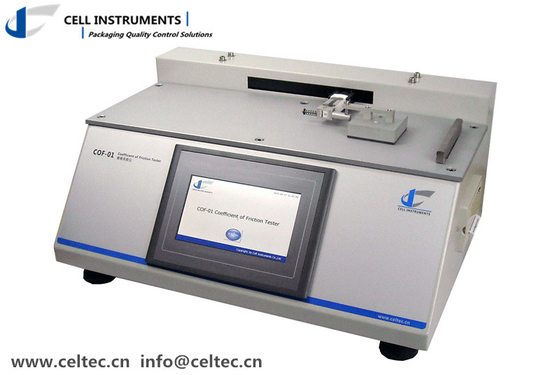

The Cof Measure—a state-of-the-art coefficient of friction tester—is designed to measure both static (starting) and kinetic (moving) friction forces. This precision instrument is primarily used for testing the coefficient of friction (Cof) in various materials such as plastic films, sheets, rubber, paper, and paperboard. The Cof Measure adheres to international standards including ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, ensuring that the results are highly reliable and accurate.

The Cof Measure is an essential tool for industries that require precise and efficient testing of material properties, including packaging, food, medicine, and beverage sectors, among others. By accurately determining the coefficient of friction, this instrument provides valuable insights that help optimize the quality and performance of materials used in production and packaging.

Key Features of the Cof Measure: Coefficient of Friction Tester

-

Advanced PLC Control with Touch Screen Operation

-

The Cof Measure features a PLC (Programmable Logic Controller) with a user-friendly touch screen interface. This simplifies operation and ensures accurate, real-time monitoring of test data and results.

-

-

Real-Time Data and Curve Display

-

The device offers a real-time display of both test data and friction curves, allowing users to closely monitor results and make adjustments as necessary. This feature enhances the overall testing experience and streamlines the analysis process.

-

-

Dual Testing Capability for Static and Kinetic Friction

-

One of the key advantages of the Cof Measure is its ability to measure both static (starting) and kinetic (moving) coefficients of friction. This dual functionality is critical for industries that need to test the friction properties of different materials under varying conditions.

-

-

Compliance with International Standards

-

The Cof Measure complies with several international standards, including ASTM D1894, ISO 8295, TAPPI T816, and GB 10006. This ensures the reliability and global applicability of the test results, making it suitable for various industrial applications.

-

-

Accurate Test Results and Curve Analysis

-

The Cof Measure provides precise calculations and analysis of friction data, making it easy to interpret results. Users can also overlay curves for a more detailed comparison of friction performance across multiple tests.

-

-

Professional Software and Optional RS232 Output

-

The optional RS232 output and professional software package enable seamless integration with other systems for further analysis, storage, and reporting of test results.

-

-

Microprint for Easy Test Result Printing

-

The Cof Measure comes equipped with a microprint feature, allowing users to print test results effortlessly. This ensures that test data is readily available for documentation and review.

-

Technical Specifications

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Applications of the Cof Measure: Coefficient of Friction Testing

The Cof Measure is designed for industries that require precise testing of friction properties in various materials. Common applications include:

-

Packaging Industry

-

In the packaging industry, the coefficient of friction is a critical parameter in ensuring that materials slide smoothly during production, transportation, and handling. The Cof Measure helps manufacturers ensure that packaging materials are optimized for ease of use, reducing frictional resistance while maintaining product integrity.

-

-

Food and Beverage Industry

-

The Cof Measure is essential in food and beverage packaging, where material friction affects sealing, handling, and product delivery. Testing the coefficient of friction of materials such as films and foils ensures the correct balance between smooth handling and material durability.

-

-

Medical and Pharmaceutical Packaging

-

Medical and pharmaceutical packaging requires precise material control to maintain safety and sterility. The Cof Measure assists in ensuring that packaging materials meet stringent quality standards by testing frictional properties that affect sealing and performance.

-

-

Paper and Cardboard Testing

-

The Cof Measure is also widely used in the paper and cardboard industries to test the friction of paperboard used for packaging. This is crucial for determining how easily paper and cardboard materials can be handled during manufacturing and processing.

-

Standards for Coefficient of Friction Testing

The Cof Measure is designed in accordance with several key international standards, including:

-

ASTM D1894: Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

-

ISO 8295: Plastics—Film and Sheeting—Determination of the Coefficient of Friction

-

TAPPI T816: Coefficient of Friction of Paper and Paperboard

-

GB 10006: Chinese National Standard for Coefficient of Friction of Packaging Materials

These standards ensure that the Cof Measure provides accurate and reliable results, making it suitable for global testing needs.

Benefits of Using the Cof Measure

-

Enhanced Efficiency and Accuracy

-

The Cof Measure improves efficiency in testing by providing fast, real-time results. Its accuracy in determining the coefficient of friction ensures that manufacturers can make data-driven decisions for material selection and processing.

-

-

User-Friendly Interface

-

The intuitive PLC control and touch screen operation make it easy for operators to set up and run tests without requiring extensive training or technical expertise.

-

-

Flexible Testing Options

-

With customizable sleds and stroke adjustments, the Cof Measure can be tailored to a wide range of materials and testing conditions, providing versatility for diverse testing needs.

-