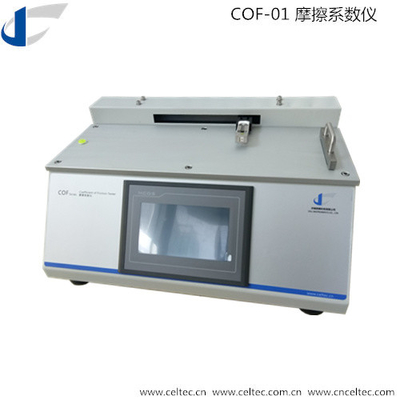

Material Slid Surface Frictional COF Tester Static & Kinetic Coefficients Of Friction Testing Of Packaging Films

| Power | 110~220V | Usage | Paper Testing Instrument,Textile Testing Instrument,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

Material Slid Surface Frictional COF Tester – Precise Static & Kinetic Coefficient of Friction Testing for Packaging Films

Introduction

The Material Slid Surface Frictional COF Tester is an advanced laboratory instrument designed for measuring the static and kinetic coefficients of friction of various packaging materials. This essential testing equipment is widely used in industries such as packaging, food, pharmaceuticals, beverages, and research institutions to evaluate material smoothness, roughness, and sliding properties.

This Material Slid Surface Frictional COF Tester ensures accurate friction analysis by simulating real-world conditions, enabling manufacturers to optimize product quality and performance. It adheres to multiple international testing standards, providing reliable and repeatable results.

![]()

Working Principle

The Material Slid Surface Frictional COF Tester operates by placing two samples together—one fixed on a flat surface and another subjected to a controlled force by a sled. As the sled moves, the friction force between the surfaces is measured to determine the static and kinetic coefficients of friction.

This method allows for comprehensive material characterization, helping manufacturers understand the frictional properties of films, coatings, laminates, and other packaging substrates. The ability to measure both static and dynamic friction is crucial for optimizing material handling, processing, and application.

Key Features

-

Advanced PLC Control: Ensures precision and ease of use with an intuitive touch screen interface.

-

Real-Time Data Display: Instant access to test data, results, and graphical curves.

-

Dual Friction Measurement: Measures both static and kinetic coefficients of friction.

-

International Standard Compliance: Conforms to ASTM D1894, ISO 8295, TAPPI T816, and GB 10006.

-

Comprehensive Data Analysis: Test results are automatically calculated, analyzed, and presented with curve superposition.

-

RS232 Interface & Software Integration: Enables seamless data export for further analysis.

-

Microprinter Output: Allows for easy printing of test results for documentation and quality control.

Technical Specifications

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Applications

The Material Slid Surface Frictional COF Tester is widely used in quality control and research laboratories for testing:

-

Plastic Films & Laminates: To assess slip properties and ensure smooth material handling.

-

Paper & Cardboard: To evaluate friction for printing and packaging applications.

-

Textiles & Nonwoven Materials: To analyze the texture and usability of fabrics.

-

Coatings & Adhesives: To determine the efficiency of surface treatments and bonding characteristics.

-

Medical & Pharmaceutical Packaging: To maintain consistency and reliability in packaging materials.

Importance of Coefficient of Friction Testing

Understanding the coefficient of friction is essential in product design and manufacturing. High friction may cause processing issues, such as jamming or excessive wear, while low friction may lead to slippage and instability. The Material Slid Surface Frictional COF Tester helps industries optimize:

-

Material Performance: Ensuring consistent quality and functionality.

-

Production Efficiency: Minimizing material waste and machine downtime.

-

End-User Satisfaction: Enhancing packaging usability and handling convenience.

Compliance with International Standards

The Material Slid Surface Frictional COF Tester complies with globally recognized testing standards, ensuring precision and consistency:

-

ASTM D1894 – Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting.

-

ISO 8295 – Measurement of Coefficients of Friction of Plastic Film and Sheeting.

-

TAPPI T816 – Coefficient of Static Friction (Slide Angle) of Packaging Materials.

-

GB 10006 – Determination of Friction Coefficient for Plastic Films.

Why Choose Our Material Slid Surface Frictional COF Tester?

-

High Accuracy & Reliability: Ensures precise friction measurement with state-of-the-art technology.

-

User-Friendly Operation: Simplified testing process with touchscreen interface and automated calculations.

-

Versatile Applications: Suitable for a wide range of materials across multiple industries.

-

Global Standard Compliance: Meets international testing requirements for credibility and reliability.

-

Customizable Solutions: Adaptable test parameters to suit specific industrial needs.

Conclusion

The Material Slid Surface Frictional COF Tester is an indispensable tool for evaluating material frictional properties, ensuring superior quality control in packaging, food, pharmaceuticals, and beyond. Its precision measurement, ease of use, and compliance with international standards make it the ideal solution for laboratory testing and industrial applications.

For more information or to request a quote, contact us today!