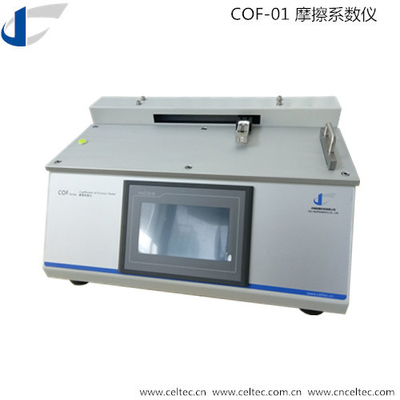

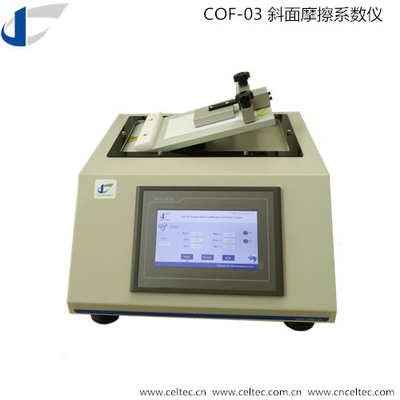

Friction Coefficient Instrument For Thin Films Coefficient of Friction COF Testing Machine

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Friction Coefficient Instrument For Thin Film | High-Precision COF Tester

Overview of the Friction Coefficient Instrument For Thin Film

The Friction Coefficient Instrument For Thin Film is an advanced testing device designed to measure the static and kinetic coefficients of friction (COF) for thin films, plastic sheets, rubber, paper, and paperboard. It is an essential tool for laboratories in the packaging, food, pharmaceutical, and materials research industries to ensure quality control and compliance with international testing standards.

Equipped with PLC control and a user-friendly touch screen, this instrument provides high-precision, real-time test results with intuitive data analysis capabilities. Whether you are testing plastic film surfaces, paperboard interactions, or rubber coatings, this COF tester ensures accurate and reliable performance to optimize material properties.

![]()

Working Principle of the Friction Coefficient Instrument For Thin Film

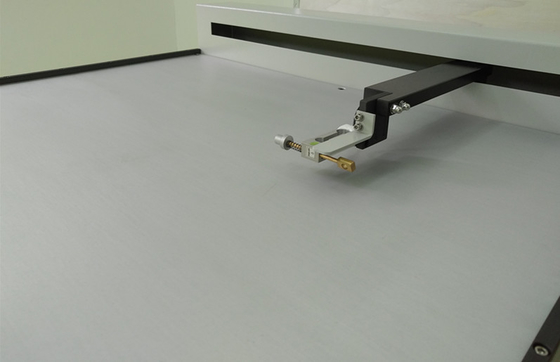

The Friction Coefficient Instrument For Thin Film operates by placing two samples together:

-

A long strip sample is fixed on a flat surface.

-

A square sample is placed on top and subjected to force via a sled.

-

The friction force is measured as the samples slip against each other.

By measuring both static and kinetic coefficients of friction, this instrument helps determine the smoothness, surface uniformity, and usability of thin film materials.

Key Features of the Friction Coefficient Instrument For Thin Film

-

Dual-Function Testing: Measures both static COF and kinetic COF with high accuracy.

-

PLC Control & Touch Screen: Intuitive operation for easy data input and monitoring.

-

Real-Time Data Display: View test results, curves, and analysis instantly.

-

Compliance with International Standards: Conforms to ASTM D1894, ISO 8295, TAPPI T816, and GB 10006.

-

Multiple Data Analysis Options: Test results calculation, curve superposition, and statistical analysis.

-

Customizable Test Parameters: Adjustable stroke length, sled weight, and test speed based on industry requirements.

-

RS232 Output & Software Integration: Connect to external software for enhanced data processing.

-

Built-in Microprinter: Allows instant printing of test results for documentation and analysis.

Applications of the Friction Coefficient Instrument For Thin Film

This COF testing instrument is widely used in various industries to optimize material performance:

-

Plastic Packaging: Evaluates film-to-film friction properties in food and pharmaceutical packaging.

-

Paper & Board Manufacturing: Assesses slip characteristics of coated and uncoated paper.

-

Rubber & Polymer Testing: Determines the surface properties of elastomers and synthetic films.

-

Textiles & Laminates: Measures fabric smoothness and interlayer interactions.

-

Medical & Pharmaceutical Films: Ensures precision testing for biomedical films and sterile packaging.

Technical Specifications of the Friction Coefficient Instrument For Thin Film

| Specification | Value |

|---|---|

| Load Cell | 5 N |

| Accuracy | ±0.5% F.S. |

| Stroke | Adjustable |

| Sled Weight | 200 g (Customizable) |

| Sled Dimensions | 63.5mm x 63.5mm (Customizable) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

Standards Compliance

The Friction Coefficient Instrument For Thin Film is compliant with the following international standards:

-

ASTM D1894 - Standard Test Method for Static and Kinetic COF of Plastic Film and Sheeting.

-

ISO 8295 - International standard for measuring friction coefficients of plastic films and sheets.

-

TAPPI T816 - COF testing method for paper and paperboard.

-

GB 10006 - National standard for COF measurement in flexible packaging materials.

Advantages of Using the Friction Coefficient Instrument For Thin Film

-

Enhanced Quality Control: Accurately determines film friction for packaging stability and usability.

-

High Precision Testing: Provides repeatable and reliable test results.

-

User-Friendly Interface: PLC-based touch screen with simple navigation.

-

Multiple Industry Applications: Suitable for plastic, paper, rubber, textiles, and medical films.

-

Data Management & Analysis: Integrated software support with RS232 output for seamless data transfer.

-

Robust Construction: Durable design for long-term laboratory use.

Why Choose Our Friction Coefficient Instrument For Thin Film?

-

Superior Accuracy: ±0.5% full-scale accuracy ensures consistent results.

-

Global Standards Compliance: Meets ASTM, ISO, TAPPI, and GB requirements.

-

Customizable Parameters: Adjustable stroke length, sled weight, and test speeds.

-

Real-Time Data Display & Printing: Live test monitoring and built-in microprinter.

-

Reliable Performance: Stable and precise testing for diverse material properties.

How to Use the Friction Coefficient Instrument For Thin Film?

-

Prepare the Samples: Cut the test samples as per the standard size requirements.

-

Set the Parameters: Adjust sled weight, test speed, and stroke length according to the material being tested.

-

Start the Test: Place the film samples on the test surface and apply force using the sled.

-

Monitor Real-Time Data: The COF tester records static and kinetic friction values automatically.

-

Analyze Results: Review test data, print reports, or export results via RS232 software.