Film Paper Surface Friction Coefficient Tester TAPPI T815 And ISO 8295 Conformed COF Tester 1 - 2 Sets

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Film Paper Surface Friction Coefficient Tester TAPPI T815 And ISO 8295 Conformed COF Tester 1 - 2 Sets

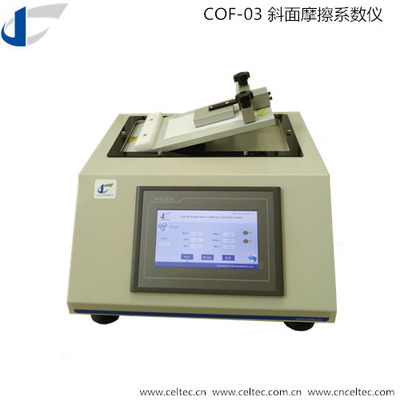

The Paper Surface Friction Coefficient Tester is a high-precision instrument designed to measure the static and kinetic coefficients of friction of various materials, including paper, plastic films, rubber, and paperboard. This tester is essential for industries such as packaging, printing, food, pharmaceutical, and research laboratories, ensuring material quality and optimizing production processes.

Manufactured in compliance with ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, the Paper Surface Friction Coefficient Tester delivers accurate and reliable results, helping manufacturers meet international quality standards.

Key Features of the Paper Surface Friction Coefficient Tester

-

High-Precision Measurement: Accurately determines both static and kinetic coefficients of friction for various substrates.

-

PLC Control & Touch Screen Operation: Ensures a user-friendly interface with real-time data display.

-

Real-Time Graphical Representation: Displays test data, curves, and analysis for better interpretation.

-

Versatile Application: Suitable for testing friction properties of paper, plastic film, coatings, and rubber materials.

-

Customizable Sled & Test Speed: Allows flexibility to meet different international standards and test requirements.

-

Automated Calculation & Analysis: Provides instant results with an integrated microprinter for easy documentation.

-

Professional Software Integration: Compatible with RS232 output for detailed data processing and report generation.

Test Principle

The Paper Surface Friction Coefficient Tester operates by placing two samples together. One long strip sample is affixed to a flat surface, while a square sample is subjected to a controlled force using a sled. The friction force is then measured when the materials slide against each other, determining the static and kinetic coefficients of friction.

Technical Specifications

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Applications of the Paper Surface Friction Coefficient Tester

The Paper Surface Friction Coefficient Tester is widely used in industries that require precise surface friction analysis, including:

-

Packaging Industry: To evaluate slip properties of paper and plastic films for efficient material handling.

-

Printing Industry: Ensures proper adhesion and print quality on coated papers and flexible packaging.

-

Pharmaceutical & Food Packaging: Assesses friction properties of flexible films used in protective packaging.

-

Research & Development Laboratories: Helps develop new materials with optimized surface characteristics.

Advantages of Using the Paper Surface Friction Coefficient Tester

-

Enhanced Quality Control: Ensures product consistency and performance in industrial applications.

-

Compliance with International Standards: Meets ASTM, ISO, and TAPPI testing guidelines for accurate results.

-

User-Friendly Interface: PLC-controlled system with touch screen operation for easy test execution.

-

Customizable Parameters: Adjustable sled weight and stroke length cater to various test conditions.

-

Real-Time Data Analysis: Generates graphical test results and reports for comprehensive evaluation.

Why Choose Our Paper Surface Friction Coefficient Tester?

-

Trusted by Global Manufacturers: Used in packaging, food, and pharmaceutical industries worldwide.

-

Durable & Reliable: Engineered for long-term, high-precision testing.

-

Customization Available: Tailored sled weights and test parameters for specific industry needs.

-

Expert Support & Service: Backed by professional technical assistance and training.

Compliance with International Standards

The Paper Surface Friction Coefficient Tester conforms to the following internationally recognized standards:

-

ASTM D1894: Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

-

ISO 8295: Plastics – Determination of the Coefficients of Friction

-

TAPPI T816: Coefficient of Static Friction (Paper to Paper)

-

GB 10006: Chinese National Standard for Friction Testing

Conclusion

The Paper Surface Friction Coefficient Tester is a critical instrument for industries that rely on precise friction measurements to ensure product quality and efficiency. With advanced automation, high precision, and international compliance, this tester is the ideal solution for laboratories and manufacturers requiring reliable friction coefficient analysis.

![]()

![]()