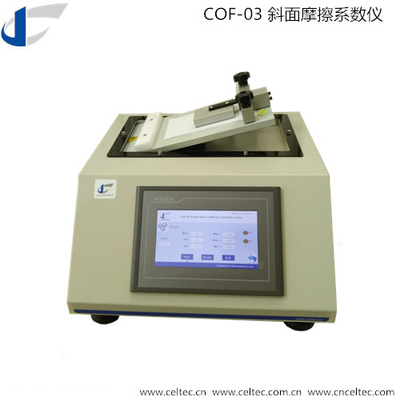

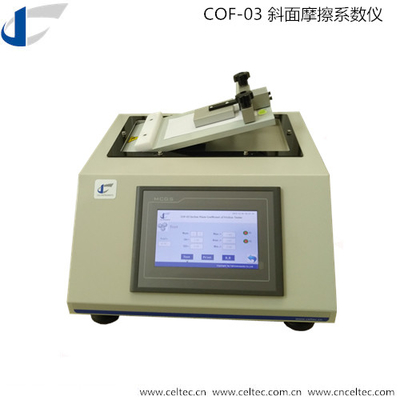

Coefficient of Friction Tester Friction Tester Plastic Film Quality Control Testing Equipment Coefficient of Friction Tester

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Friction Tester – Precision Testing for Static and Kinetic Coefficients of Friction

![]()

The Friction Tester is a specialized laboratory instrument designed to measure the static and kinetic coefficients of friction (COF) for a variety of materials, including plastic films, sheets, rubber, paper, and paperboard. This precision instrument ensures reliable and repeatable results, making it an essential tool for quality control in industries such as packaging, food, pharmaceuticals, printing, and manufacturing.

By accurately analyzing the surface friction characteristics of materials, the Friction Tester helps manufacturers optimize material performance, enhance product quality, and comply with international testing standards. Whether assessing the smoothness of printed packaging or evaluating the slip resistance of food wraps, this instrument provides critical data that supports material development and quality assurance.

Working Principle of the Friction Tester

The Friction Tester operates based on a standardized testing procedure where two samples are placed in contact with each other under controlled conditions. The test involves the following steps:

-

A long strip sample is securely fixed onto the flat test surface.

-

A square sample is attached to a sled, which is then moved over the strip sample at a consistent speed.

-

The instrument measures the force required to initiate and maintain the movement, providing static and kinetic coefficient of friction values.

-

The results are displayed in real-time and can be analyzed using specialized software for detailed material performance insights.

This precise method allows for repeatable and standardized COF measurements, ensuring compliance with international testing requirements.

Key Features of the Friction Tester

-

Advanced PLC control system for stable and precise operation.

-

Touchscreen interface for intuitive navigation and user-friendly operation.

-

Real-time data display of test parameters, results, and graphical analysis.

-

Dual COF measurement: Simultaneous measurement of both static and kinetic coefficient of friction.

-

Compliance with multiple international testing standards, including ASTM D1894, ISO 8295, TAPPI T816, and GB 10006.

-

Automated test result calculation, analysis, and curve superposition, enabling comprehensive data interpretation.

-

RS232 output and professional software (optional) for seamless data transfer and reporting.

-

Microprinter connectivity for quick and easy printing of test results.

-

Customizable sled weight and stroke to accommodate various testing requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Cell | 5 N |

| Accuracy | ±0.5% F.S. |

| Stroke | Customizable |

| Sled Weight | 200 g (63.5mm x 63.5mm) (Customization Available) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

Applications of the Friction Tester

The Friction Tester is widely used in various industries to evaluate material performance and optimize production quality. Some key applications include:

-

Plastic Packaging Testing: Ensuring smooth handling and high-quality lamination in plastic films and flexible packaging materials.

-

Paper and Board Industry: Evaluating the slip resistance of printed packaging, cartons, and corrugated materials.

-

Rubber and Elastomer Quality Control: Analyzing the friction properties of rubber components used in gaskets, seals, and tires.

-

Textile and Fabric Testing: Measuring fabric surface friction for enhanced wear resistance and performance evaluation.

-

Pharmaceutical and Medical Packaging: Ensuring compliance with friction standards for blister packs, syringes, and medical-grade films.

-

Automotive and Industrial Materials: Assessing the coefficient of friction of components used in manufacturing processes.

Why Choose Our Friction Tester?

-

High Precision and Repeatability: Engineered with advanced sensors and control systems to deliver consistent and accurate results.

-

User-Friendly Interface: Intuitive touchscreen controls streamline test setup and execution.

-

Versatile Testing Capabilities: Supports a wide range of materials and industry applications.

-

Compliance with Global Standards: Ensures test validity and comparability across industries.

-

Data Analysis and Reporting: Optional software provides in-depth analysis and data visualization.

-

Customization Options: Adjustable sled weight and stroke length allow for tailored test configurations.

Industry Standards Compliance

The Friction Tester complies with major global testing standards, ensuring accuracy, reliability, and industry-wide acceptance. These standards include:

-

ASTM D1894: Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting.

-

ISO 8295: International Standard for measuring COF in plastic and rubber materials.

-

TAPPI T816: Industry benchmark for testing friction properties in paper and board products.

-

GB 10006: Chinese National Standard for COF measurement in polymer films and sheets.

How the Friction Tester Enhances Material Performance

The Friction Tester plays a critical role in material development and quality assurance by:

-

Improving Product Consistency: Helps manufacturers maintain uniform friction properties across production batches.

-

Enhancing Production Efficiency: Identifies friction-related issues that may impact packaging and processing speeds.

-

Ensuring Consumer Safety: Determines optimal slip resistance in food and medical packaging applications.

-

Facilitating Research & Development: Provides essential data for developing new materials and coatings.

![]()