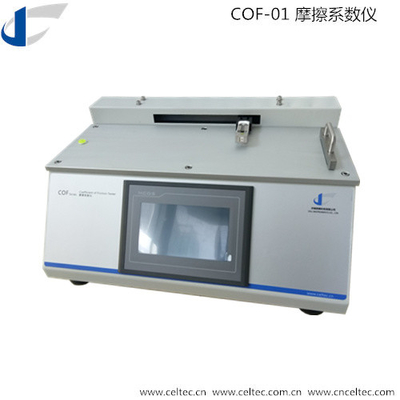

Plastic Smoothness Test Material Friction Coefficient Tester COF Tester Machine

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Plastic Smoothness Test Material Friction Coefficient Tester COF Tester Machine

![]()

A Friction Coefficient Tester is an essential instrument used to measure the static and kinetic coefficients of friction (COF) in materials such as plastic films, rubber, paper, and paperboard. This device is critical for industries where material smoothness plays a significant role in product functionality, including packaging, food, medicine, and beverage sectors. The Friction Coefficient Tester is designed to test and evaluate the interaction between two surfaces, providing accurate data on the frictional resistance during their movement.

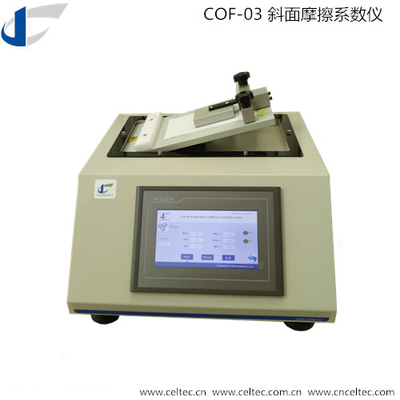

Test Principle of the Friction Coefficient Tester

The Friction Coefficient Tester works by placing two samples together. A long strip sample is securely fixed to a flat surface, while a squared sample is placed on top of it. A sled is then used to apply force, and the friction force is measured as the two samples slip against each other. This test helps determine both the static and kinetic coefficients of friction, which are essential for understanding the material's behavior in various conditions.

Technical Features of the Friction Coefficient Tester

The Friction Coefficient Tester offers a wide range of features to ensure accurate, reliable, and efficient testing:

- PLC Control and Touch Screen Operation: The tester is equipped with a PLC control system and a touch screen interface, providing an intuitive and easy-to-use control panel for users.

- Real-Time Display of Test Data and Results: The device allows users to see real-time data, results, and friction curves during testing. This instant feedback ensures that operators can quickly interpret results and make necessary adjustments.

- Measurement of Both Static and Kinetic Friction: The tester can accurately measure both the static and kinetic coefficients of friction, allowing for comprehensive analysis of material friction properties.

- Compliance with International Standards: The Friction Coefficient Tester complies with multiple international standards, ensuring its applicability in global markets and making it suitable for various industry applications.

- Test Result Calculation, Analysis, and Curve Superposition: The system calculates and analyzes test results, and the curve superposition feature provides a clear comparison between multiple tests for in-depth analysis.

- RS232 Output and Professional Software (Optional): For advanced data management and reporting, the tester offers RS232 output and optional professional software for seamless integration with laboratory systems.

- Microprinting of Test Results: The built-in microprinter allows for easy printing of test results, which is particularly useful for documentation and quality control processes.

Technical Specifications

- Load Cell: 5 N

- Accuracy: 0.5 F.S.

- Stroke: As required by user specifications

- Sled: 200 g (63.5mm x 63.5mm, customizable upon request)

- Test Speed: 100mm/min (ISO) or 150mm/min (ASTM)

Standards Compliance

The Friction Coefficient Tester meets the following international standards:

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

These certifications ensure that the device is not only reliable but also adheres to globally recognized testing procedures, making it an indispensable tool for laboratories involved in quality control, research, and development.

Applications of the Friction Coefficient Tester

The Friction Coefficient Tester is widely used across several industries, including:

- Packaging: Testing the COF of materials used in packaging helps determine how easily materials slide or adhere to one another, which is crucial for packaging functionality and ease of use.

- Food Industry: The tester ensures that packaging materials, such as plastic films, do not create unwanted friction that could hinder the packaging process or cause issues in storage and transport.

- Medical: In the medical field, the Friction Coefficient Tester is used to test the friction properties of materials used in medical packaging, ensuring that products maintain integrity during handling and transportation.

- Beverage Industry: Beverage packaging materials are also tested for friction properties to prevent issues such as sticking, tearing, or damage during filling and sealing processes.

Why Choose Our Friction Coefficient Tester?

- High Precision: Our Friction Coefficient Tester offers highly accurate measurements, ensuring that you can trust the results for product development, quality control, and research purposes.

- User-Friendly Interface: With PLC control and a touch screen operation, the tester is easy to use and provides real-time data visualization, making it efficient for operators.

- Comprehensive Testing: The ability to measure both static and kinetic friction provides a complete understanding of material behavior, making this tester versatile across various industries.

- Global Standards Compliance: With certifications in ASTM, ISO, and TAPPI standards, our Friction Coefficient Tester meets the highest global requirements for quality and performance.

- Advanced Data Analysis: The tester offers advanced features like curve superposition, data analysis, and optional professional software, ensuring in-depth test result interpretation and comparison.

Conclusion

The Friction Coefficient Tester is an essential instrument for any laboratory involved in material testing. With its accurate measurement of both static and kinetic coefficients of friction, compliance with international standards, and user-friendly features, it is a must-have tool for industries like packaging, food, medical, and beverages. Invest in our Friction Coefficient Tester today to enhance your material testing capabilities and improve the quality control processes in your lab.

![]()