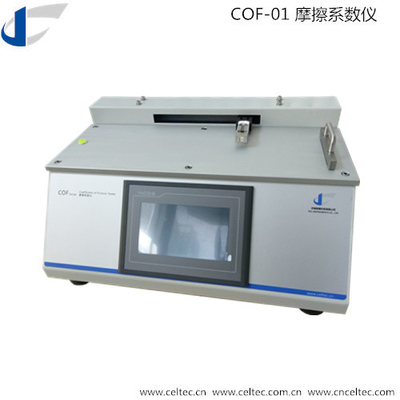

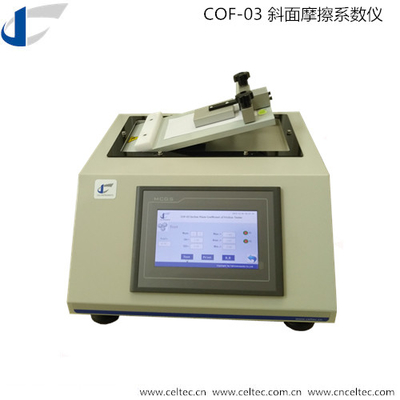

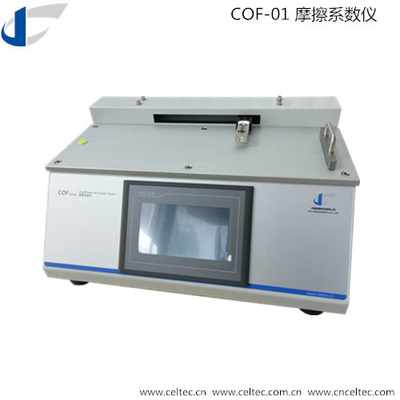

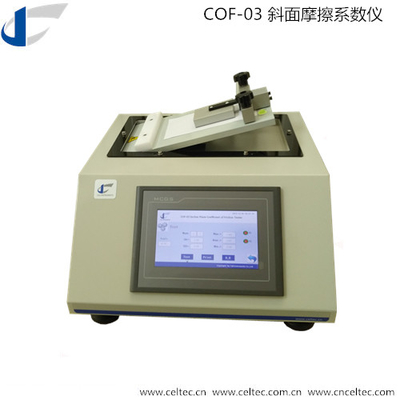

Fabric friction coefficient tester COF Testing lab testing equipment

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Fabric friction coefficient tester COF Testing lab testing equipment

![]()

The Fabric Friction Coefficient Tester is an advanced instrument designed to accurately measure both static and kinetic coefficients of friction in various materials, including fabrics, plastic films, sheets, rubber, paper, and paperboard. This device is essential for laboratories and industries aiming to assess the frictional properties of materials, ensuring quality and performance in applications such as packaging, textiles, and manufacturing.

Key Features:

-

Comprehensive Friction Analysis: Capable of determining both static and kinetic coefficients of friction, providing a complete understanding of material behavior under different conditions.

-

Advanced Control System: Equipped with a PLC control system and user-friendly touch screen interface, facilitating intuitive operation and precise control over testing parameters.

-

Real-Time Data Presentation: Offers immediate display of test data, results, and friction curves, allowing for prompt analysis and decision-making.

-

International Standard Compliance: Designed in accordance with multiple international standards, ensuring reliability and consistency in test results.

-

Versatile Data Management: Features RS232 output and optional professional software for in-depth data analysis, along with microprint capabilities for easy documentation of test results.

Technical Specifications:

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Applicable Standards:

This Fabric Friction Coefficient Tester conforms to several international testing standards, including:

-

ASTM D1894: Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting.

-

ISO 8295: Plastics—Film and Sheeting—Determination of the Coefficients of Friction.

-

TAPPI T816: Coefficient of Static Friction (Slide Angle) of Packaging and Packaging Materials (Inclined Plane Method).

-

GB 10006: Chinese National Standard for determining the coefficients of friction for plastic films and sheets.

Applications:

The Fabric Friction Coefficient Tester is widely used across various industries to evaluate the frictional properties of materials:

-

Packaging Industry: Assessing the slip resistance of packaging materials to ensure stability during transportation and storage.

-

Textile Industry: Evaluating the tactile properties of fabrics, which can influence consumer comfort and product quality.

-

Printing Industry: Determining the frictional behavior of paper and paperboard to optimize printing processes and material handling.

-

Rubber Manufacturing: Measuring the friction coefficients of rubber materials to ensure performance in various applications, such as seals and gaskets.

Supplementary Information:

Understanding the frictional properties of materials is crucial for predicting their behavior in real-world applications. The Fabric Friction Coefficient Tester provides accurate and reliable measurements, enabling manufacturers and researchers to:

![]()

-

Optimize Material Selection: Choose appropriate materials based on their frictional characteristics to enhance product performance and user experience.

-

Improve Process Efficiency: Adjust manufacturing processes to accommodate the frictional properties of materials, reducing waste and increasing productivity.

-

Ensure Compliance: Meet industry standards and regulations by verifying that materials possess the required frictional properties.

-

Enhance Product Development: Incorporate frictional data into the design process to develop products that meet specific performance criteria.