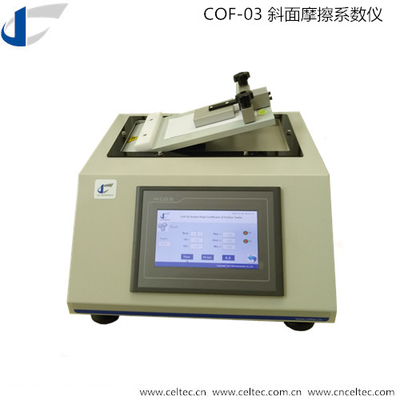

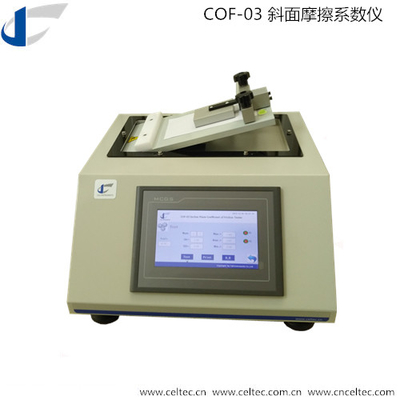

Dynamic Friction Coefficient Smoothness Of The Material Digital Film Coefficient Of Friction Tester Equipment

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Dynamic Friction Coefficient Smoothness Of The Material Digital Film Coefficient Of Friction Tester Equipment

![]()

Understanding the frictional properties of materials is crucial across various industries, including packaging, food, pharmaceuticals, beverages, and academia. The Digital Film Coefficient of Friction Tester is an advanced instrument designed to accurately measure both static and kinetic coefficients of friction in materials such as plastic films, sheets, rubber, paper, and paperboard. This precision ensures that materials meet quality standards and perform optimally in their intended applications.

Key Features of the Digital Film Coefficient of Friction Tester

-

PLC Control with Touch Screen Operation: The tester is equipped with a Programmable Logic Controller (PLC) and a user-friendly touch screen interface, facilitating intuitive operation and real-time monitoring of test parameters.

-

Real-Time Data Display: Operators can view test data, results, and curves in real-time, allowing for immediate analysis and decision-making.

-

Comprehensive Friction Measurement: Capable of measuring both static and kinetic coefficients of friction, the tester provides a complete understanding of a material's frictional behavior.

-

Compliance with International Standards: The instrument adheres to multiple international standards, including ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, ensuring reliable and standardized testing procedures.

-

Advanced Data Analysis: Features such as test result calculation, analysis, and curve superposition enable thorough examination of material properties.

-

Connectivity and Reporting: The tester includes an RS232 output for data transfer and can be paired with professional software for enhanced data management. Additionally, a microprinter is available for easy printing of test results.

Technical Specifications

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Applications Across Industries

The Digital Film Coefficient of Friction Tester is essential for industries where understanding material friction is critical:

-

Packaging Industry: Determining the frictional properties of packaging materials helps in assessing stackability and handling during transportation. A proper coefficient of friction ensures that packages do not slip or stick excessively, maintaining product integrity.

-

Food and Beverage Industry: Ensuring that packaging films used for food and beverages have appropriate frictional properties is vital for automated filling and packaging processes, reducing downtime and product waste.

-

Pharmaceuticals: In the pharmaceutical sector, the tester aids in evaluating the frictional characteristics of blister packs and other packaging materials, ensuring ease of use and safety.

-

Educational Institutions: Laboratories in colleges and universities utilize the tester for research and educational purposes, providing hands-on experience in material property analysis.

Understanding Friction Coefficients

-

Static Coefficient of Friction: This measures the force required to initiate movement between two surfaces. A higher static coefficient indicates more resistance to the start of motion, which is crucial in applications where slippage must be minimized.

-

Kinetic Coefficient of Friction: This assesses the force necessary to maintain movement between surfaces. Understanding kinetic friction is important for processes involving continuous motion, such as conveyor systems.

Testing Principle

The testing process involves placing two samples together: a long strip sample is fixed on a flat surface, and a square sample is subjected to force by a sled. The instrument measures the friction force as the samples slide against each other, providing accurate readings of both static and kinetic friction coefficients.

Advantages of Using the Digital Film Coefficient of Friction Tester

-

Enhanced Quality Control: By accurately measuring frictional properties, manufacturers can ensure that materials meet specific quality standards, leading to improved product performance and customer satisfaction.

-

Process Optimization: Understanding the frictional behavior of materials allows for optimization in manufacturing processes, reducing equipment wear and energy consumption.

-

Compliance Assurance: Adherence to international testing standards ensures that products are compliant with global regulations, facilitating smoother market entry and acceptance.

Supplementary Features

-

Data Acquisition Software: Some models come complete with data acquisition software, enabling seamless data collection and analysis.

-

Wide Speed Range: Certain testers offer a wide speed range (e.g., 10~305 mm/min), providing flexibility to simulate various real-world conditions.

-

Customizable Test Loads: Options to customize test loads (e.g., 200 g, 500 g) are available to meet specific testing requirements.

Conclusion

The Digital Film Coefficient of Friction Tester is an indispensable tool for accurately measuring the frictional properties of various materials. Its advanced features, compliance with international standards, and versatility make it essential for quality control, research, and development across multiple industries.

![]()