Coefficient Of Friction Tester/ Meter (Lab Testing Equipment)

| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Coefficient Of Friction Tester/ Meter (Lab Testing Equipment)

Introduction to Coefficient Of Friction Tester

A Coefficient Of Friction Tester is a specialized instrument used to measure the static and kinetic friction coefficients of various materials, including plastic films, sheets, rubber, paper, and paperboard. This essential laboratory equipment ensures accurate friction testing, helping industries maintain material quality and optimize production processes. By analyzing frictional properties, manufacturers can enhance material performance, improve packaging reliability, and meet regulatory standards.

Working Principle of Coefficient Of Friction Tester

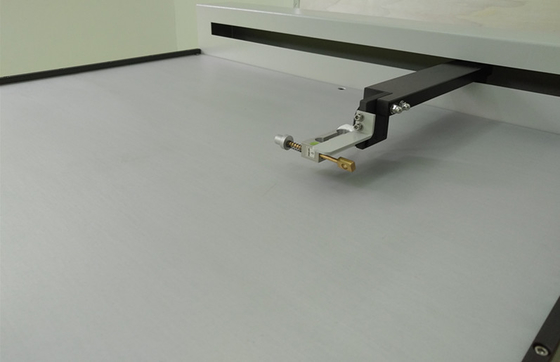

The Coefficient Of Friction Tester operates by placing two test samples together. One sample is securely fixed on a flat surface, while the other is positioned on top and subjected to a controlled force using a sled. The instrument measures the frictional force exerted when the two materials slide against each other, allowing users to determine both static and kinetic coefficients of friction accurately.

This method ensures precise results for applications requiring high material quality, such as flexible packaging, printing, adhesives, and coatings. The tester follows industry standards to guarantee repeatability and reproducibility in laboratory settings.

Key Features of Coefficient Of Friction Tester

-

Advanced PLC Control System – Provides intuitive operation with a user-friendly touchscreen interface.

-

Real-Time Data Display – Displays friction force, coefficient values, and test curves instantly.

-

Dual Measurement Capability – Simultaneous measurement of static and kinetic coefficients of friction.

-

Compliant with International Standards – Ensures reliable and standardized testing.

-

Comprehensive Analysis Tools – Test results calculation, graphical representation, and curve comparison.

-

RS232 Output and Professional Software (Optional) – Facilitates seamless data export for further analysis.

-

Integrated Microprinter – Allows quick and easy printing of test reports for record-keeping.

Technical Specifications of Coefficient Of Friction Tester

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

![]()

![]()

Industry Applications of Coefficient Of Friction Tester

1. Packaging Industry

Friction characteristics significantly impact the performance of flexible packaging materials. The Coefficient Of Friction Tester ensures that films and laminates have the right surface properties to prevent slipping or excessive adhesion during processing and transportation.

2. Printing and Coating Industry

Friction properties influence print quality and the durability of coated surfaces. A Coefficient Of Friction Tester helps determine the best material surface treatment for high-quality printing and coating applications.

3. Adhesives and Lamination Industry

Understanding the friction coefficient is crucial for optimizing adhesive formulations and lamination processes. Testing helps achieve the ideal balance between adhesion and smooth material handling.

4. Rubber and Tire Industry

The Coefficient Of Friction Tester plays a vital role in evaluating the slip resistance of rubber components, ensuring safety and performance in tire manufacturing and other rubber applications.

5. Paper and Board Industry

Paper manufacturers use friction testing to ensure that sheets have the right slip characteristics for printing, packaging, and automated handling processes.

Why Choose Our Coefficient Of Friction Tester?

-

Highly Accurate Measurements – Advanced sensors provide consistent and repeatable test results.

-

User-Friendly Design – Easy-to-operate interface with clear data visualization.

-

Customizable Options – Adjustable sled weight and stroke length to meet specific testing needs.

-

Durable and Reliable – Built with high-quality materials to ensure long-term performance.

-

Global Standard Compliance – Adheres to ASTM D1894, ISO 8295, TAPPI T816, and GB 10006 regulations.

Standards Compliance

Our Coefficient Of Friction Tester complies with multiple international standards, ensuring global usability and high precision in material testing:

-

ASTM D1894 – Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting.

-

ISO 8295 – Measurement of friction properties of plastic films and sheets.

-

TAPPI T816 – Friction testing of paper and board materials.

-

GB 10006 – Chinese standard for measuring friction properties of flexible materials.

Additional Features of Coefficient Of Friction Tester

-

Automatic Data Processing – Eliminates manual calculations, reducing human error.

-

Graphical Data Analysis – Allows users to compare test results effectively.

-

Compact and Space-Saving Design – Ideal for laboratory and industrial environments.

-

Low Maintenance Requirements – Ensures long-lasting operation with minimal upkeep.

How to Use the Coefficient Of Friction Tester?

-

Prepare Samples: Cut test materials according to standard dimensions.

-

Secure the Base Sample: Fix one sample onto the flat testing surface.

-

Position the Sled Sample: Place the second sample on top, connected to the sled.

-

Start the Test: The instrument applies force, measuring static and kinetic friction.

-

Analyze Results: The system calculates friction coefficients and displays data in real-time.

Conclusion

The Coefficient Of Friction Tester is an essential tool for industries requiring precise friction analysis. Whether in packaging, printing, adhesives, rubber, or paper manufacturing, this instrument provides accurate and repeatable measurements to ensure quality control. By complying with global standards, it offers reliable testing for research and production environments. Choose our Coefficient Of Friction Tester for superior performance, user-friendly operation, and industry-leading accuracy.