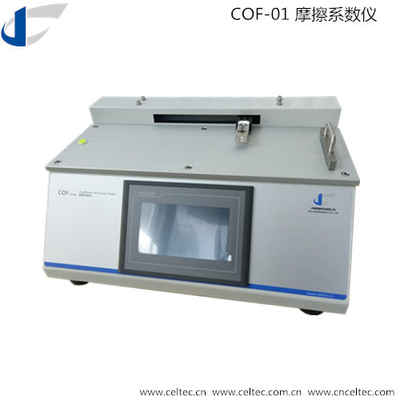

Lab Testing Equipment Coefficient of Friction Tester for pPE/LTPE/OPP/ PVC/ PPT/BOPP

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Power | Electronic | Usage | Paper Testing Instrument,Textile Testing Instrument,Other,Plastic Testing Machine |

|---|---|---|---|

| Standard | ISO8295,ASTM D1894 | Warranty | 12 Months |

| Product Name | Packaging Materials Coefficient Of Friction Tester | Function | Kinetic And Static Coefficients Of Coefficient Of Friction Test,coefficient Friction Tester,detecting Dynamic Frition Coefficient |

| Power Supply | 110~220V |

Lab Testing Equipment Coefficient of Friction Tester for pPE/LTPE/OPP/ PVC/ PPT/BOPP

![]()

Background

Understanding the coefficient of friction is crucial in evaluating the interaction between different surfaces. In packaging, it directly impacts the efficiency of processes like stacking, cartoning, and palletization. A lower coefficient suggests smoother movement, while a higher one implies more resistance. Managing this factor is paramount for optimizing packaging performance throughout production, transit, and storage.

Application

Our COF-01 Coefficient of Friction Tester is engineered to precisely measure static and kinetic coefficients of friction across a wide array of materials. From plastic films to rubber, paper, and metal-plastic composites, it ensures accurate assessments essential for various industries including packaging, automotive, textiles, and more.

Standards

![]()

Our tester adheres to industry standards such as ASTM D1894, ISO 8295, TAPPI T816, and GB 10006, ensuring reliable and consistent results for your testing needs.

Formula

The coefficient of friction (COF) is calculated by dividing the force required to move one surface over another by the perpendicular force. It encompasses both static (μs) and kinetic (μd) coefficients, each offering distinct insights into material behavior crucial for packaging design and production.

Technical Features

![]()

- Precision Control: PLC control and an intuitive HMI touch screen ensure ease of operation and accurate results.

- Robust Design: Built with industrial-grade materials and powered by a stepper motor and precision ball lead screw for stability and longevity.

- Real-time Data: Provides real-time test curves and automatically records key metrics like maximum, minimum, and average test results.

- Comprehensive Testing: Capable of measuring both static and kinetic coefficients of friction, catering to diverse testing requirements.

- Versatile Compatibility: Supports various materials and testing standards, offering flexibility and reliability.

- Efficient Reporting: Equipped with a dot matrix microprinter for convenient documentation.

- Durable Construction: The test plane, constructed entirely from aluminum, ensures durability and accuracy in testing.

- Enhanced Connectivity: Features RS232 output and optional professional software for advanced data analysis.

- User-Friendly Interface: Supports local language display for enhanced accessibility and usability.

![]()

![]()

Static And Kinetic Friction Tester ( C.O.F ) technical Features

- PLC control and touch screen operation

- Real-time display of test data, results, and curves

- Both the static and kinetic coefficient of friction can be measured

- In accordance with multiple international standards

- Test results calculation, analysis, and curve superposition

- RS232 output and professional software(optional)

- Microprint of easy printing of test result

Technical Specification

| Load Cell | 5 N |

| Accuracy | 0.5 F.S. |

| Stroke | As Required |

| Sled | 200 g 63.5mm*63.5mm(Customization Available) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

![]()

![]()

Standards

ASTM D1894, ISO 8295, TAPPI T816, GB 10006

![]()

![]()