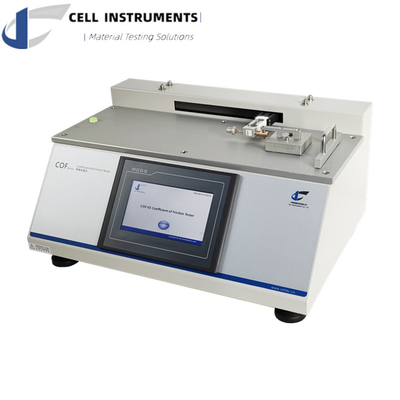

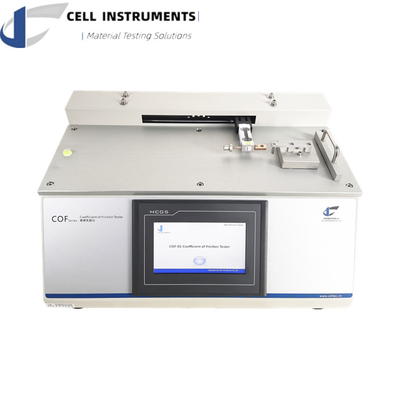

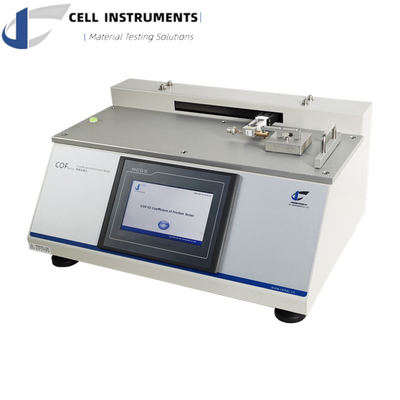

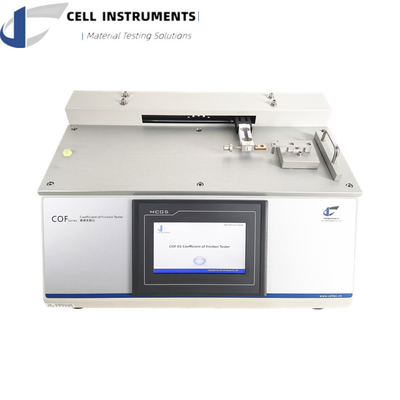

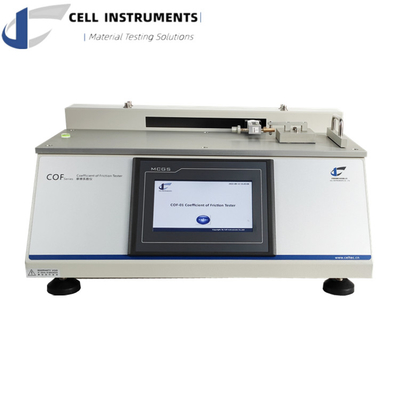

Coefficient Of Friction Tester Plastic Film Friction Tester ASTM D1894 Tester COF Testing Equipment

| Load Cell | 5 N(or As Required) | Accuracy | 0.5 F.S. |

|---|---|---|---|

| Sled | 200±1g (or As Required) | Sled Size | 63.5mm*63.5mm (or As Required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) | Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg | Power | 110~220V 50/60Hz |

Coefficient Of Friction Tester Plastic Film Friction Tester ASTM D1894 Tester COF Testing Equipment

Product Description:

Main Parameter

| COF-01 Coefficient of Friction Tester | |

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Introduction to the COF-01 Coefficient of Friction Tester

In the realm of materials testing, understanding and measuring the coefficient of friction is critical. This parameter, which quantifies the interaction between two surfaces, is essential for determining how materials will behave under different conditions. Our COF-01 Coefficient of Friction Tester is engineered to deliver precise measurements of both static and kinetic coefficients of friction, providing valuable insights into the performance and suitability of various materials across diverse industries.

Importance of Measuring the Coefficient of Friction

The coefficient of friction plays a pivotal role in determining the ease with which materials slide over one another. A lower coefficient of friction indicates smoother sliding surfaces, which is crucial in applications where minimal resistance is desired. Conversely, a higher coefficient suggests greater frictional force, which can be beneficial or detrimental depending on the specific application.

Numerous factors influence the coefficient of friction, including surface treatments, additives, and environmental conditions. For example, antiblock additives, corona treatment, antistatic agents, inks, varnishes, and adhesives can all significantly affect frictional properties. Therefore, accurately measuring the coefficient of friction is vital for quality control and ensuring that materials meet the required performance standards.

Applications of the COF-01 Coefficient of Friction Tester

The COF-01 Coefficient of Friction Tester is a versatile instrument designed to cater to a wide range of industries and applications. Its ability to measure both static and kinetic coefficients of friction makes it an invaluable tool for:

- Plastic Films: In the packaging industry, the slipperiness of plastic films is crucial for ensuring smooth processing and handling. The COF-01 helps manufacturers assess and control the friction properties of their films, enhancing performance and usability.

- Sheets and Rubber: The friction characteristics of rubber and sheet materials are essential for applications in manufacturing, automotive, and construction. Our tester provides accurate measurements to help determine their suitability for various uses.

- Paper and Paperboard: In the printing and packaging industries, understanding the friction properties of paper and paperboard is vital for optimizing production processes and ensuring product quality.

- Woven and Non-Woven Fabrics: For industries like fashion, furniture, and medical textiles, the friction properties of fabrics can affect product performance and durability. The COF-01 enables precise measurement of these properties.

- Metal-Plastic Composite Belts: In telecommunications and material handling, evaluating the frictional performance of communication cables and conveyor belts is critical for maintaining operational efficiency.

- Wood, Coatings, Brake Pads, and Windshield Wipers: The COF-01 aids in assessing the frictional characteristics of materials used in construction, automotive, and other critical applications, ensuring safety and reliability.

- Shoe Materials and Tires: In the footwear and automotive industries, the slipperiness of shoe materials and tires is a major safety concern. Our tester helps manufacturers optimize these materials for better performance.

Standards Compliance

Our COF-01 Coefficient of Friction Tester meets and exceeds several prominent international standards, including ASTM D1709 and ISO 8295. Compliance with these standards ensures that your friction coefficient measurements are accurate, reliable, and universally accepted. The tester also adheres to TAPPI T816 and GB 10006 standards, further validating its precision and dependability.

Key Features and Benefits

The COF-01 Coefficient of Friction Tester is designed with advanced features to provide the highest level of accuracy and reliability:

- Accurate Testing: The COF-01 offers precise measurements of both static and kinetic coefficients of friction, providing comprehensive data for material assessment.

- Versatility: Capable of testing a wide range of materials, including plastic films, rubber, paper, textiles, and metal-plastic composites, making it suitable for various industries.

- Standards Compliance: Meets ASTM D1709, ISO 8295, TAPPI T816, and GB 10006 standards, ensuring compatibility with industry requirements and guaranteeing trustworthy results.

- User-Friendly Interface: The tester is equipped with an intuitive interface, making it easy to operate and configure for different testing scenarios.

- Robust Construction: Built with high-quality materials, the COF-01 is designed for durability and long-term use in demanding laboratory environments.

- Comprehensive Data Reporting: Provides detailed test reports that help in analyzing and documenting friction properties, aiding in quality control and research.

Why Choose the COF-01 Coefficient of Friction Tester?

Selecting the COF-01 Coefficient of Friction Tester means choosing a reliable and accurate instrument that supports your quality control processes. Whether you're in the packaging, food, medicine, or any other industry, our tester provides the precision needed to ensure the optimal performance of your materials. By understanding and controlling the frictional properties of your products, you can improve efficiency, enhance product quality, and ensure customer satisfaction.

Conclusion

Ensure the accuracy and reliability of your coefficient of friction testing with our advanced COF-01 Coefficient of Friction Tester. Whether you are in the packaging, food, medicine, or any other industry, our tester delivers precise measurements for improved performance and efficiency. Adhering to ASTM D1709 and ISO 8295 standards, the COF-01 is your trusted partner in achieving superior material quality. Contact us for more information or to discuss your specific testing needs. Experience the reliability and accuracy of our COF-01 Coefficient of Friction Tester and elevate your material testing to the next level.

![]()

![]()

![]()