Inclined Plane Coefficient Of Friction Tester For plastic film Best Plastic Packaging Coefficient of Friction Tester COF

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Angle Range | 0° ~ 60° | Accuracy | 0.01° |

|---|---|---|---|

| Stroke | 0.1°/s ~ 10.0°/s | Sled | 200g, 235g, Or 1300g(choose One Or Others) |

Inclined Plane Coefficient Of Friction Tester For plastic film Best Plastic Packaging Coefficient of Friction Tester COF

| Angle range | 0° ~ 60° |

| Accuracy | 0.01° |

| Stroke | 0.1°/s ~ 10.0°/s |

| Sled | 200g, 235g, or 1300g(choose one or others) |

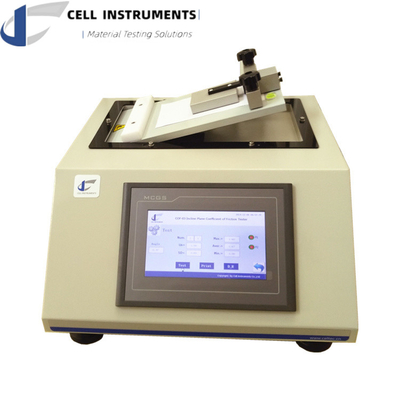

Inclined Plane Coefficient of Friction Tester: Precision Testing for Material Physics

The Inclined Plane Coefficient of Friction Tester is a state-of-the-art instrument designed to accurately measure the static coefficient of friction (COF) for various materials. Whether you are in packaging, food, medicine, beverages, or academic research, this precision testing tool ensures your materials meet international standards. The Inclined Plane Coefficient of Friction Tester offers exceptional versatility with PLC control, real-time data display, and comprehensive testing capabilities to suit a broad range of industries.

Introduction to the Inclined Plane Coefficient of Friction Tester

The Inclined Plane Coefficient of Friction Tester (Model COF-03) is engineered for precise measurement of static friction in materials such as plastic films, sheets, rubber, paper, board, and more. This sophisticated tool operates by placing a test surface on a variable inclined plane, allowing accurate measurement of the force required to initiate sliding against another inclined surface. This technology ensures highly reliable and repeatable results, making it an essential instrument for laboratories and industries where friction plays a critical role in material performance.

Why Choose Our Inclined Plane Coefficient of Friction Tester?

- Accurate Measurements: The tester provides highly accurate results, allowing you to determine the static coefficient of friction for materials ranging from plastic films to coatings. This is crucial for ensuring the quality and functionality of packaging materials, product safety, and regulatory compliance.

- Versatility Across Industries: Whether for packaging films, food and beverage containers, pharmaceutical packaging, or academic research, the Inclined Plane Coefficient of Friction Tester is adaptable to various material types and testing needs.

- Compliant with Industry Standards: The Inclined Plane Coefficient of Friction Tester meets industry standards such as ASTM D202, ASTM D4918, and TAPPI T816, ensuring your tests are aligned with globally recognized guidelines.

- Intuitive Interface and Easy Operation: Featuring PLC control and an HMI touch screen, this tester allows users to easily manage test parameters and monitor real-time data, providing clear results with minimal effort.

How the Inclined Plane Coefficient of Friction Tester Works

The Inclined Plane Coefficient of Friction Tester determines the static COF by gradually increasing the incline of the testing surface. As the angle of the inclined plane increases, the force required to initiate sliding is measured. This force is numerically equivalent to the tangent of the angle at which sliding begins, providing a precise value for the static coefficient of friction.

This process is beneficial in analyzing how materials interact under different conditions, making it invaluable for industries where controlling friction is necessary for functionality, durability, and safety.

Key Features of the Inclined Plane Coefficient of Friction Tester:

- PLC Control & HMI Touch Screen: Provides easy-to-use, intuitive control over the testing process.

- Real-Time Data Display: Shows maximum, minimum, average, and standard deviation values.

- Multi-Surface Testing: Suitable for a wide range of materials, from plastic films to rubber, paper, coatings, and woven fabrics.

- RS232 and Professional Software Integration: Optional features for data transfer and further analysis.

- High Precision and Accuracy: With an angle range from 0° to 60° and an accuracy of 0.01°, the tester delivers precise and repeatable results.

Material Applications & Industry Use

The Inclined Plane Coefficient of Friction Tester is indispensable in industries such as:

- Packaging: Evaluating the frictional properties of plastic films, coatings, and packaging materials to optimize functionality.

- Food & Beverage: Ensuring packaging materials maintain integrity and ease of handling during production and transportation.

- Pharmaceuticals: Testing the friction properties of materials used in pharmaceutical packaging to ensure safety and compliance.

- Research and Academia: Supporting material physics research by providing accurate COF data for various substrates.

Coefficient of Friction and Its Importance

The static coefficient of friction (COF) is a key factor in understanding how materials behave when they come into contact with one another. This measurement is crucial for several reasons:

- Material Selection: Helps determine the suitability of materials for various applications, especially in packaging, where friction affects performance during sealing, handling, and transportation.

- Quality Control: Ensures that products meet the necessary frictional standards required for optimal performance.

- Product Safety: By controlling friction, manufacturers can reduce the risk of materials slipping or failing during use, thus improving product safety.

Standards Complied With:

- ASTM D202: Standard test method for the coefficient of friction of plastic film.

- ASTM D4918: Standard test method for evaluating the static COF of plastic film.

- TAPPI T816: Standard for measuring the coefficient of friction of paper and paperboard.

Technical Specifications

- Angle Range: 0° to 60°

- Accuracy: 0.01°

- Stroke: 0.1°/s to 10.0°/s

- Sled Options: 200g, 235g, or 1300g (selectable based on the material being tested)

Why Invest in the Inclined Plane Coefficient of Friction Tester?

This Inclined Plane Coefficient of Friction Tester provides critical insights into the physical properties of materials, helping you select the right materials, maintain product quality, and ensure safety standards. Whether you are working in packaging, pharmaceuticals, food and beverage, or academic research, this precision tool ensures that your testing is both reliable and compliant with international standards.

By investing in this versatile testing instrument, you will improve your quality control processes, reduce production risks, and meet the regulatory requirements of your industry.

![]()

![]()