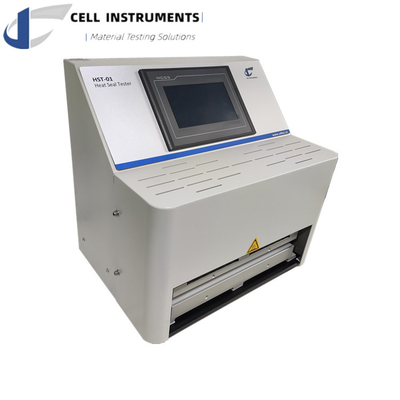

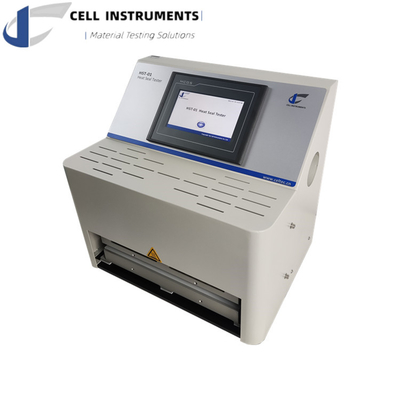

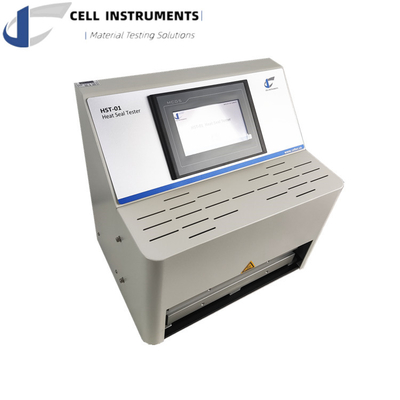

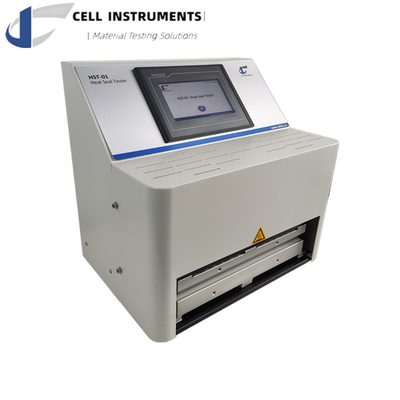

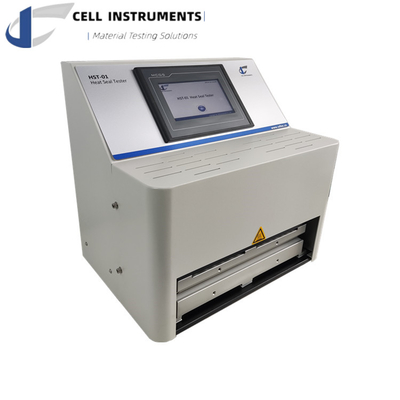

Plastic Packaging Heat Seal Testing Machine Heat Seal Tester For Plastic Film ASTM F2029 Film Heat Sealability Tester

| Sealing Temp. | Ambient~300℃ | Deviation | ±0.2℃ |

|---|---|---|---|

| Sealing Time | 0.1S~9999S | Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 Mm L*W | Gas Pressure | 0.7 MPa |

| Port Size | Ф6 Mm PU Hose | Power | AC 220V 50Hz |

Plastic Packaging Heat Seal Testing Machine Heat Seal Tester For Plastic Film ASTM F2029 Film Heat Sealability Tester

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

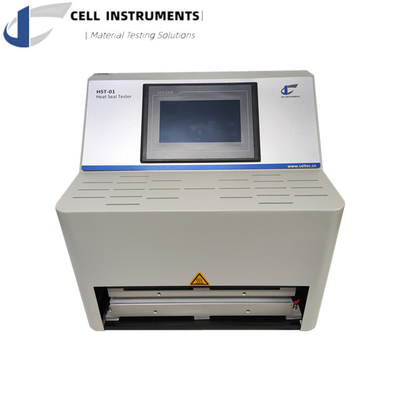

Introduction to the Plastic Packaging Heat Seal Testing Machine

The Plastic Packaging Heat Seal Testing Machine, also known as the HST-01 Heat Seal Tester, is a high-precision laboratory instrument designed to assess the heat sealability of plastic films, laminates, polymers, and composites. This essential testing machine plays a crucial role in ensuring the durability, integrity, and reliability of seals in flexible packaging across various industries, including packaging, food, beverage, medicine, and academic research.

Heat sealing is a critical process in packaging, where thermoplastic materials are bonded through heat and pressure. With the HST-01, manufacturers can perform detailed evaluations to ensure that their packaging materials meet required standards for strength, durability, and ease of use. Whether it's for plastic bags, food packaging, medical packaging, or beverage seals, the Plastic Packaging Heat Seal Testing Machine is vital for guaranteeing the quality of the final product.

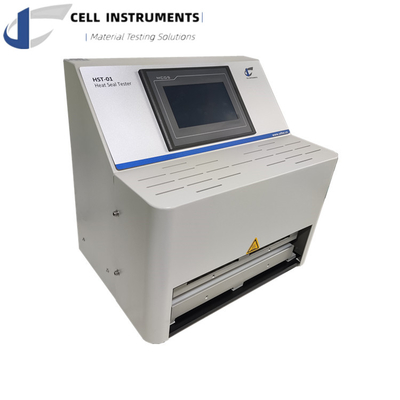

Key Features of the Plastic Packaging Heat Seal Testing Machine (HST-01)

-

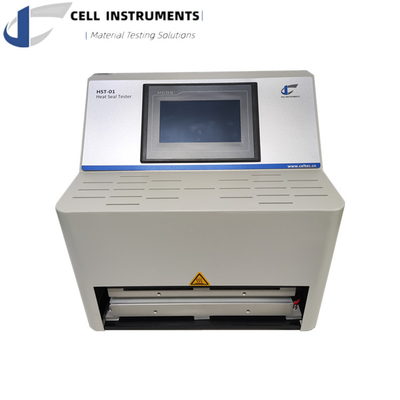

Advanced Control System: The HST-01 Heat Seal Tester is equipped with a PLC (Programmable Logic Controller) system and an intuitive HMI (Human-Machine Interface) touchscreen, providing ease of use and precise control over test parameters.

-

Temperature and Pressure Control: The machine offers consistent and accurate temperature regulation with a P.I.D. (Proportional-Integral-Derivative) controller. Sealing temperature is adjustable from ambient to 300°C, with an accuracy of ±0.2°C. This ensures reliable testing for various material types.

-

Safety and Reliability: Featuring an anti-scald front cover and high-quality aluminum construction for reduced heat loss, the HST-01 prioritizes user safety while maintaining operational reliability. Additionally, the proximity sensor ensures that seal initiation is perfectly synchronized with the testing process.

-

Compliance with Industry Standards: The Plastic Packaging Heat Seal Testing Machine complies with ASTM F2029-16(2021) standards, ensuring that heat sealing tests are performed according to international guidelines for laboratory-based testing of flexible barrier materials.

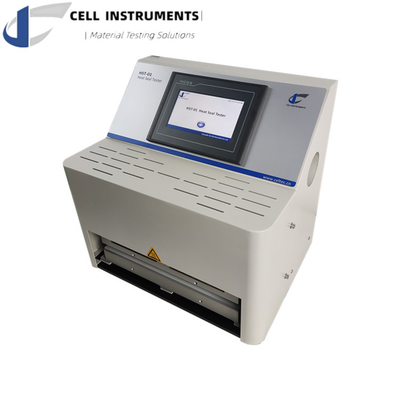

Why Choose the HST-01 Heat Seal Tester for Plastic Packaging?

-

Versatile Applications: Ideal for industries like packaging, food, beverage, pharmaceuticals, and academia, the HST-01 is perfect for testing plastic films, laminates, and composite materials used in a wide range of packaging applications.

-

Customizable Settings: The Plastic Packaging Heat Seal Testing Machine can be customized with different seal jaw sizes, shapes, and patterns, enabling you to test a variety of material configurations. The ability to customize allows manufacturers to test new materials or packaging designs effectively.

-

Enhanced Testing Precision: With the ability to control sealing time (from 0.1 seconds to 9999 seconds) and sealing pressure (0.15 to 0.7 MPa), this machine provides highly accurate and repeatable results, making it an ideal solution for research and quality control applications.

-

Advanced Data Output: The HST-01 comes equipped with an RS 232 COM Port and optional computer software for data logging and analysis. This feature allows for enhanced functionality and seamless integration into laboratory workflows.

-

Proven Durability and Reliability: Designed for consistent performance, the HST-01 Heat Seal Tester provides long-lasting durability even under high-volume testing conditions.

Technical Specifications

| Specification | Value |

|---|---|

| Sealing Temperature | Ambient ~ 300°C |

| Temperature Deviation | ± 0.2°C |

| Sealing Time | 0.1S ~ 9999S |

| Sealing Pressure | 0.15 ~ 0.7 MPa |

| Seal Jaws Dimensions | 330 mm x 10 mm (L x W) |

| Gas Pressure | 0.7 MPa |

| Port Size | Ø6 mm PU Hose |

| Power Supply | AC 220V 50Hz |

Customization Options for the Plastic Packaging Heat Seal Testing Machine

- Seal Jaw Customization: Customizable seal jaw dimensions, shapes, and patterns are available to meet your specific testing needs.

- Software Integration: Optionally, you can integrate with computer software for advanced data analysis and reporting, enhancing the testing process.

By choosing the Plastic Packaging Heat Seal Testing Machine, you ensure that your materials undergo rigorous testing for heat sealability, leading to more reliable packaging solutions that meet global standards.

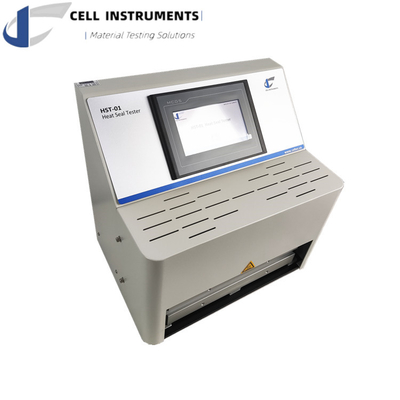

Applications of the Plastic Packaging Heat Seal Testing Machine

- Food Packaging: Ensures the integrity of heat seals in food packaging, preventing contamination and spoilage.

- Medical Packaging: Verifies the reliability of seals in medical packaging to guarantee sterility and safety.

- Beverage Packaging: Tests the seal quality of beverage containers, ensuring that they maintain freshness and safety.

- Academic Research: Used in research labs for exploring new materials and testing the effectiveness of sealant technologies in packaging.

Conclusion

The Plastic Packaging Heat Seal Testing Machine is an indispensable tool for ensuring the quality and reliability of heat seals in plastic packaging. With its precise control over sealing time, temperature, and pressure, this machine provides the necessary functionality to meet the highest standards in the packaging industry. Whether for food, medicine, or beverage packaging, the HST-01 guarantees accurate, repeatable results to support quality assurance and research efforts.

![]()

![]()