ASTM D3078 Bubble Emission Waterproof Bag Pressure Decay Testing Machine Leakage Tester For Plastic Bloated Packaging

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Accuracy | 1% | Detection Range | 0~-90KPa |

|---|---|---|---|

| Dimensions | Φ270 X H210mm | Display | HMI Screen |

| Name | Vacuum Leak Detector | Power Supply | Battery/AC |

| Vacuum Measurement | Digital | Weight | 16kg |

ASTM D3078 Bubble Emission Waterproof Bag Pressure Decay Testing Machine Leakage Tester For Plastic Bloated Packaging

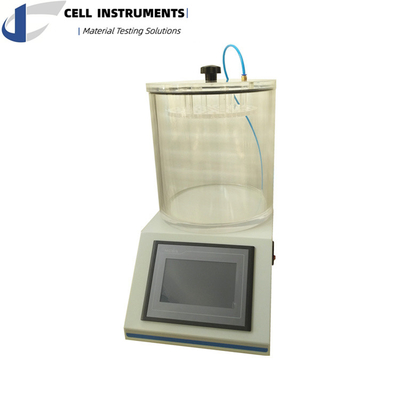

Introduction to the Bag Pressure Decay Testing Machine

Ensuring package integrity is crucial for maintaining product quality, preventing contamination, and complying with industry standards. The Bag Pressure Decay Testing Machine is designed to detect leaks in plastic bloated packaging with high accuracy, making it an essential tool for industries such as food, pharmaceuticals, and packaging. This advanced testing system identifies leaks through precise vacuum pressure decay analysis, ensuring reliable results for quality control and production optimization.

Why Choose a Bag Pressure Decay Testing Machine?

1. Ensuring Packaging Reliability

The Bag Pressure Decay Testing Machine helps manufacturers ensure that their packaging meets strict industry regulations. By detecting leaks in packaging materials, it prevents product spoilage, contamination, and wastage, ultimately improving overall product safety and customer satisfaction.

2. Compliance with ASTM D3078 and Other Industry Standards

This testing machine follows the ASTM D3078 bubble emission test method and other recognized standards, making it ideal for evaluating the integrity of packaging seals. Companies in pharmaceuticals, medical devices, and food industries can confidently use this equipment to ensure compliance with quality control requirements.

3. Advanced Vacuum Leak Detection Technology

Utilizing state-of-the-art vacuum pressure decay technology, the Bag Pressure Decay Testing Machine detects leaks with precision. The machine applies controlled vacuum levels to test samples, ensuring accurate detection of micro-leaks that may otherwise go unnoticed.

Test Description and Working Principle

1. Precision Vacuum Leak Testing

The testing process begins by placing the sample inside a transparent, water-filled vacuum chamber. The Bag Pressure Decay Testing Machine applies a controlled vacuum pressure to the packaging, and any leaks are identified through bubble emission or sample deformation.

2. Visual Confirmation of Leaks

The machine offers real-time visual confirmation of leaks. When air escapes from the packaging due to pressure differences, bubbles form at leak sites. This method provides an immediate and accurate indication of leakage points.

3. Seal Integrity Verification

In cases where no bubbles appear, the machine evaluates sample expansion and recovery to determine sealing performance. The ability to monitor pressure variations ensures that even minor defects are detected.

Technical Features of the Bag Pressure Decay Testing Machine

-

PLC-Controlled System for Stability

-

The machine features an industrial-grade PLC control system, ensuring stable and reliable operation for continuous use.

-

-

Precision Vacuum Control with Venturi Tube

-

Instead of traditional vacuum pumps, the Bag Pressure Decay Testing Machine uses a Venturi tube system to create a stable vacuum of up to -90 KPa, optimizing efficiency and reducing maintenance costs.

-

-

User-Friendly Touchscreen Interface

-

The integrated HMI touchscreen allows operators to set test parameters easily, store test conditions, and retrieve data efficiently.

-

-

Multiple Parameter Storage Capability

-

The machine can save up to five groups of test parameters, allowing users to switch between different test conditions seamlessly.

-

-

Customizable Chamber Sizes

-

The standard transparent acrylic chamber is designed for clear visibility and can be customized to accommodate different package sizes and shapes.

-

Additional Features for Enhanced Usability

-

Micro Printer Integration – Enables easy documentation of test results for compliance tracking.

-

Multi-Language Support – Customizable interface for international users.

-

Vacuum Pump Compatibility – Option to integrate an external vacuum pump for achieving higher vacuum levels.

-

Durable and Ergonomic Design – Built for long-term industrial applications with robust construction.

Applications of the Bag Pressure Decay Testing Machine

This testing machine is widely used in industries requiring stringent package integrity testing:

-

Food and Beverage Packaging – Ensures airtight seals for extended shelf life.

-

Pharmaceuticals and Medical Devices – Verifies packaging integrity to maintain sterility and safety.

-

Industrial and Consumer Goods Packaging – Detects leaks in flexible and rigid packaging solutions.

-

R&D and Laboratory Testing – Supports new packaging development and quality assurance programs.

Main Parameters

| Specification | Details |

|---|---|

| Test Range | 0 to -90 KPa |

| Chamber Type | Acrylic cylinder, customizable |

| Chamber Dimensions | Φ270 x H210 mm (usable space) |

| Compressed Air Requirement | 0.7 MPa (provided by user) |

| Power Supply | 110~220V, 50/60Hz |

| Available Chamber Shapes | Cylindrical and cuboid |

![]()

| Test Range | 0~-90 KPa |

| Chamber | Acrylic Cylinder Shape |

| Test Space | Φ270*H210mm (Inside Usable) |

| Compressed Air | 0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

![]()

![]()