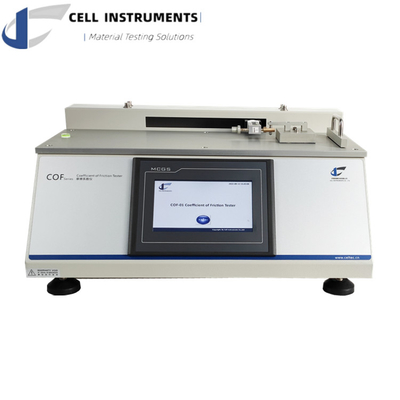

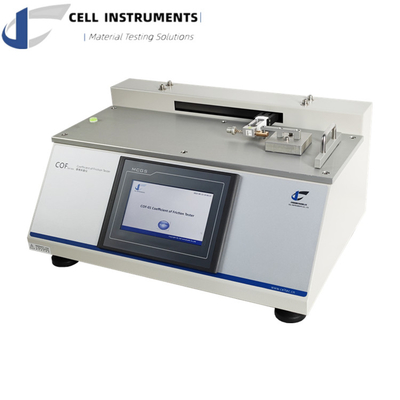

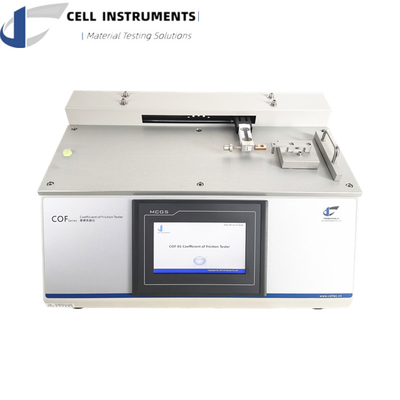

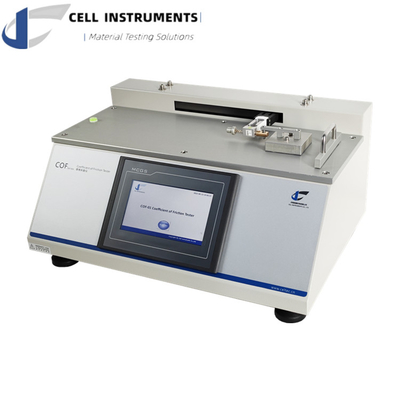

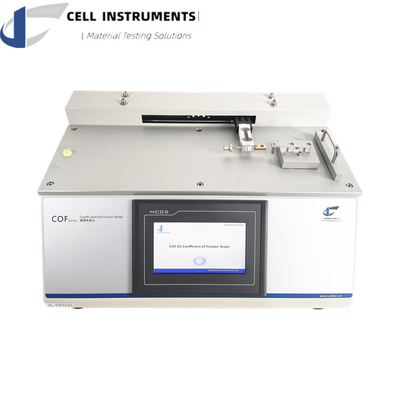

Paper And Paperboard Coefficient Of Friction Tester COF Tester For Conveyor Belt Materials Astm D1894 Packaging Tester

| Load Cell | 5 N(or As Required) | Accuracy | 0.5 F.S. |

|---|---|---|---|

| Sled | 200±1g (or As Required) | Sled Size | 63.5mm*63.5mm (or As Required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) | Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg | Power | 110~220V 50/60Hz |

Paper And Paperboard Coefficient Of Friction Tester COF Tester For Conveyor Belt Materials Astm D1894 Packaging Tester

![]()

Introduction to the Paperboard Coefficient of Friction Tester

The Paperboard Coefficient of Friction Tester is a state-of-the-art instrument designed to accurately measure the frictional properties of various materials, including paperboard. As a critical parameter in material testing, the coefficient of friction (COF) plays a significant role in determining the ease or difficulty with which materials slide against one another. This measurement is vital for industries where the smooth interaction of surfaces is essential, such as packaging, manufacturing, automotive, and food production. With our Paperboard Coefficient of Friction Tester, businesses can ensure the performance and quality of their materials meet stringent industry standards.

Why the Coefficient of Friction Matters

The coefficient of friction is a key physical property that influences the handling, processing, and performance of materials. Whether it's paper, plastic, rubber, or fabric, the friction between surfaces determines how materials behave during use. For paperboard and packaging, low friction is often desirable to allow smooth movement during processing, whereas higher friction may be needed in applications like adhesive bonding. The Paperboard Coefficient of Friction Tester enables precise measurement of both static and kinetic friction coefficients, ensuring the materials meet specific requirements for various applications.

Applications of the Paperboard Coefficient of Friction Tester

Our COF-01 Paperboard Coefficient of Friction Tester is a versatile tool suitable for testing a wide range of materials, making it ideal for industries that require friction analysis. Here are the key applications:

-

Paper and Paperboard Testing

The Paperboard Coefficient of Friction Tester excels in measuring the friction characteristics of paper and paperboard, ensuring these materials are suitable for use in packaging, printing, and other industries where consistent and controlled friction is essential. -

Plastic Films

For industries like packaging, where the quality of plastic films is paramount, this tester measures the friction between layers of plastic, ensuring that films slide correctly during manufacturing and transport. -

Rubber and Sheets

The COF-01 Tester is also suitable for evaluating rubber and sheet materials used in automotive, construction, and industrial applications. It ensures that these materials perform optimally under various conditions. -

Textile Materials

In the textile industry, understanding friction properties is essential for producing high-quality fabrics. The Paperboard Coefficient of Friction Tester helps assess woven and non-woven textiles, ensuring smooth processing and end-use performance. -

Conveyor Belt Materials

For industries relying on conveyor belts, such as telecommunications and material handling, this tester evaluates the friction properties of composite materials to ensure efficient operation.

Key Industry Standards for the Paperboard Coefficient of Friction Tester

The COF-01 Paperboard Coefficient of Friction Tester meets international industry standards, ensuring reliable and accurate results. It complies with the following key standards:

- ASTM D1894

- ISO 8295

- TAPPI T816

- GB 10006

These certifications demonstrate that our tester is designed to deliver high-quality, standardized measurements across various materials, including paperboard.

Technical Features of the Paperboard Coefficient of Friction Tester

The COF-01 Paperboard Coefficient of Friction Tester is built to provide accurate and repeatable measurements, incorporating several advanced features:

- PLC Control and HMI Touch Screen: The industrial-grade control system ensures ease of use, stability, and long-lasting performance.

- Precision Testing Mechanism: Powered by a stepper motor and a precision ball lead screw, the tester offers exceptional accuracy and control.

- Real-Time Data Display: During testing, real-time data is displayed, with automatic recording of maximum, minimum, and average results, helping users assess material performance quickly.

- Versatility: Measures both static and kinetic coefficients of friction, making it suitable for a wide variety of applications.

Main Parameters of the Paperboard Coefficient of Friction Tester

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Why Choose Our Paperboard Coefficient of Friction Tester?

The Paperboard Coefficient of Friction Tester is a reliable, precise, and easy-to-use instrument that guarantees accurate friction measurements for paperboard, plastic films, textiles, and other materials. By providing detailed friction data, the COF-01 Tester empowers industries such as packaging, food, pharmaceuticals, and automotive to improve their material handling processes, reduce product defects, and enhance manufacturing efficiency. Whether you're testing packaging materials for slip resistance or ensuring the quality of paperboard products, our tester provides the information you need to optimize your production processes.

Industries That Benefit from the Paperboard Coefficient of Friction Tester

Our Paperboard Coefficient of Friction Tester is crucial for various industries, including:

- Packaging: Ensures materials like paperboard and plastic films have the correct friction properties for smooth processing.

- Food Industry: Tests packaging materials to ensure they meet quality standards and perform efficiently during production and transport.

- Pharmaceuticals: Ensures that packaging materials used for medical and pharmaceutical products meet regulatory requirements for friction properties.

- Textiles: Aids in the testing of friction properties of fabrics for clothing, upholstery, and other textile applications.

- Automotive: Evaluates friction in materials used in vehicle components like rubber, belts, and other surfaces.

Conclusion

In today's competitive marketplace, ensuring the right friction properties in materials is essential for product quality and performance. The Paperboard Coefficient of Friction Tester from Cell Instruments provides precise, reliable, and repeatable measurements for paperboard, plastic films, rubber, textiles, and more. It complies with industry standards like ASTM D1894 and ISO 8295, offering confidence in every test result. Invest in the COF-01 Paperboard Coefficient of Friction Tester to enhance the quality, efficiency, and safety of your materials and products.

![]()