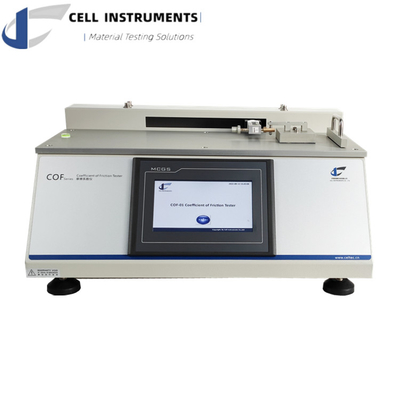

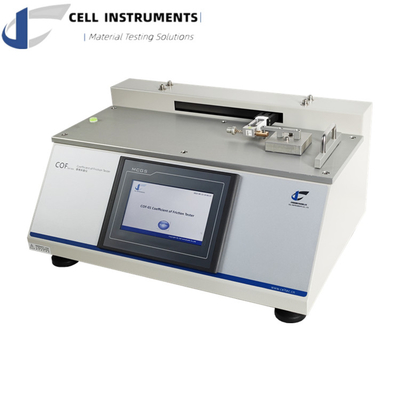

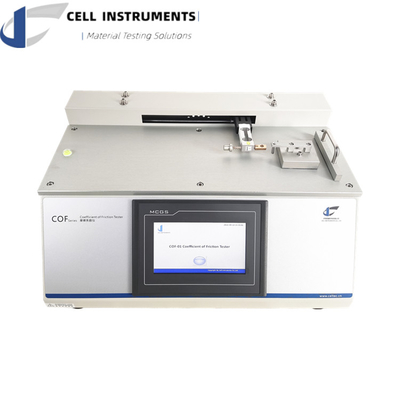

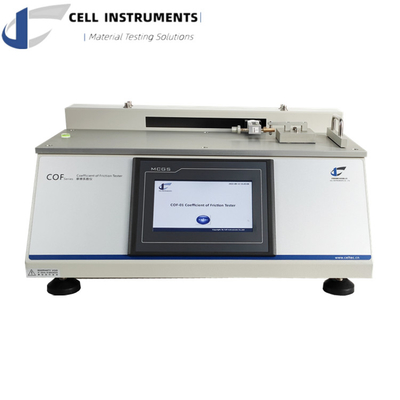

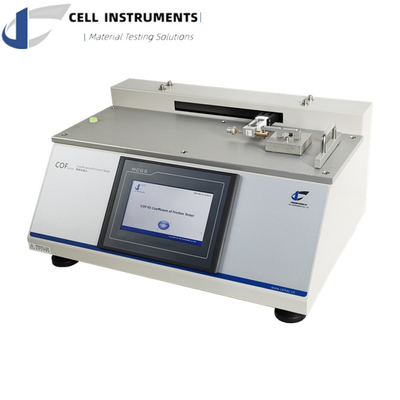

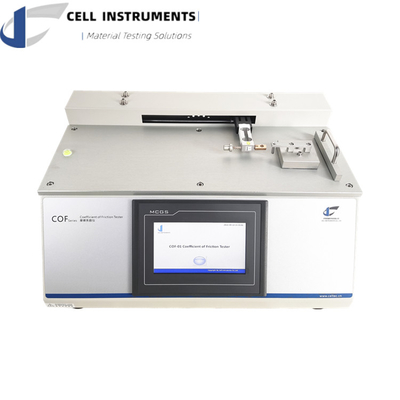

Aluminum Foil Material Friction Testing Equipment Coefficient Of Friction Instrument For Textile TAPPI T816 COF Tester

| Load Cell | 5 N(or As Required) | Accuracy | 0.5 F.S. |

|---|---|---|---|

| Sled | 200±1g (or As Required) | Sled Size | 63.5mm*63.5mm (or As Required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) | Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg | Power | 110~220V 50/60Hz |

Aluminum Foil Material Friction Testing Equipment Coefficient Of Friction Instrument For Textile TAPPI T816 COF Tester

![]()

Material Friction Testing Equipment: Ensuring Precision and Quality in Materials Testing

In the world of materials testing, understanding and measuring the coefficient of friction is essential to ensure the optimal performance of materials in various applications. Our Material Friction Testing Equipment is designed to provide precise and reliable results when evaluating the frictional properties of different materials, from plastics and rubber to paper, textiles, and metals. By using this testing equipment, industries such as packaging, automotive, textiles, and more can ensure their materials meet the required standards for performance and quality.

Introduction to Material Friction Testing Equipment

Material Friction Testing Equipment plays a crucial role in analyzing how different materials interact with one another in terms of friction. The coefficient of friction (COF) is the measurement that indicates the level of resistance between two materials as they move against each other. Lower coefficients of friction typically mean that two surfaces slide more easily, while higher values indicate that more force is required for movement. Understanding and controlling this property is essential in applications where smooth material flow, safety, and performance are critical.

This Material Friction Testing Equipment is designed for testing both static and kinetic coefficients of friction across a wide range of materials, allowing industries to measure how materials behave under real-world conditions. With precise control over testing parameters, you can ensure that your materials meet or exceed industry standards for quality.

Importance of Coefficient of Friction Testing

The coefficient of friction is influenced by various factors, including additives like antiblock agents, corona treatment, antistatic agents, and more. Additionally, coatings, inks, varnishes, and adhesives can all impact the frictional properties of materials. By accurately testing the coefficient of friction, you can ensure that materials will perform as expected during their lifecycle.

Our Material Friction Testing Equipment is perfect for industries where friction plays a pivotal role, including packaging, food processing, pharmaceuticals, automotive, and textiles. Whether you are testing the slipperiness of plastic films, rubber sheets, paperboard, or fabrics, our equipment will help you achieve accurate, reproducible results.

Applications of Material Friction Testing Equipment

The Material Friction Testing Equipment is highly versatile and is designed to test the friction properties of a variety of materials used in different industries:

-

Plastic Films: The COF-01 tester evaluates the slipperiness of plastic films, a crucial factor in industries like packaging, where precise friction properties ensure smooth handling during processing and transport.

-

Rubber and Sheets: Testing the friction characteristics of rubber and various sheets can help determine their suitability for manufacturing, automotive, and construction applications, where frictional properties are crucial for performance.

-

Paper and Paperboard: The tester is perfect for the packaging and printing industries, providing valuable data on the friction characteristics of paper and paperboard to ensure smooth processing during production and handling.

-

Woven and Non-Woven Fabrics: Understanding the friction properties of fabrics helps industries like fashion, medical textiles, and furniture design. Our equipment provides accurate measurements to ensure optimal product performance.

-

Metal-Plastic Composites: Evaluate composite materials used in telecommunications, conveyor belts, and other critical applications to ensure they meet performance standards.

-

Wood, Coatings, Brake Pads, and Windshield Wipers: Assess friction characteristics of materials used in construction, automotive, and safety-related products.

-

Shoe Materials and Tires: The COF-01 is ideal for testing footwear and tire materials, ensuring that friction levels are suitable for safety and performance in real-world conditions.

Industry Standards for Material Friction Testing Equipment

Our Material Friction Testing Equipment adheres to internationally recognized standards, ensuring the accuracy and reliability of the test results. The equipment meets the following key standards:

- ASTM D1894 – Standard Test Method for Static and Kinetic Coefficients of Friction of Plastics and Coatings

- ISO 8295 – Plastics: Film and Sheeting – Determination of the Coefficient of Friction

- TAPPI T816 – Test Method for Friction of Paper and Paperboard

- GB 10006 – Chinese National Standard for the Coefficient of Friction of Packaging Materials

By following these standards, you can be confident that your tests will produce data that is both accurate and reliable, providing the information necessary for optimizing your material performance.

Technical Features of Material Friction Testing Equipment

Our Material Friction Testing Equipment is built with cutting-edge technology to ensure stability, accuracy, and ease of use. Key features include:

-

PLC Control and HMI Touch Screen: Provides intuitive operation with a user-friendly interface, making it easy to manage tests and view results in real time.

-

Precision Mechanism: Powered by a stepper motor and precision ball lead screw, this equipment guarantees accuracy during testing, ensuring reliable results.

-

Real-Time Data Display: Test curves are displayed in real time, allowing you to monitor the results as the test progresses. Automatic recording of the maximum, minimum, and average values ensures comprehensive data collection.

-

Versatility in Testing: Capable of measuring both static and kinetic coefficients of friction across a wide range of materials, making it suitable for diverse applications.

Main Parameters

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Why Choose Our Material Friction Testing Equipment?

- Precision and Reliability: Our equipment ensures accurate friction testing, providing consistent and repeatable results.

- Compliance with Industry Standards: Meets global testing standards such as ASTM, ISO, and TAPPI, ensuring the credibility of your results.

- User-Friendly Design: The intuitive touch screen interface and real-time data display make it easy to operate and understand the results.

- Versatile Applications: Ideal for testing a wide range of materials, including plastic films, paperboard, textiles, rubber, and more.

Conclusion

Our Material Friction Testing Equipment is the ideal solution for industries that require precise and reliable measurements of frictional properties. Whether you are testing packaging materials, textiles, or automotive components, this equipment will help you ensure that your products meet the highest standards of performance and safety. Contact us today to learn more about how our testing solutions can benefit your business.

For more information, please visit our website.

![]()