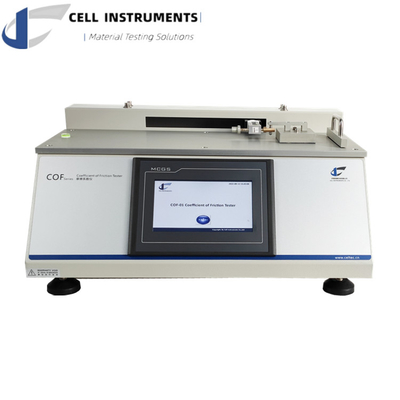

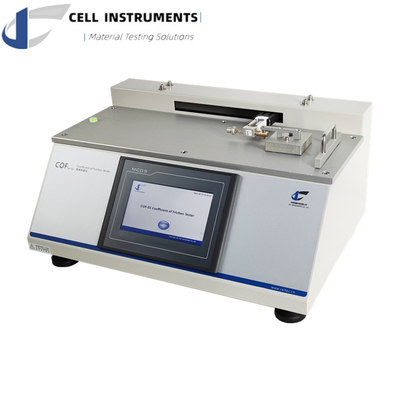

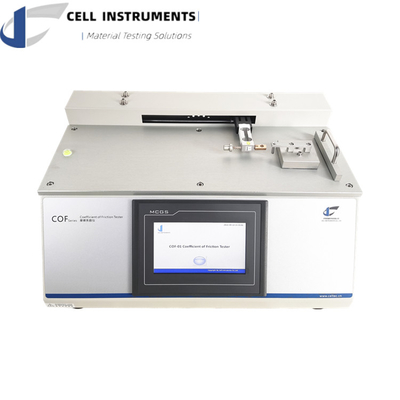

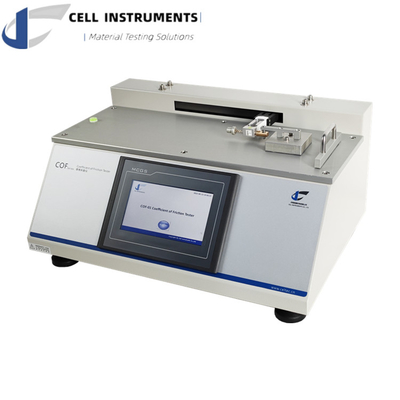

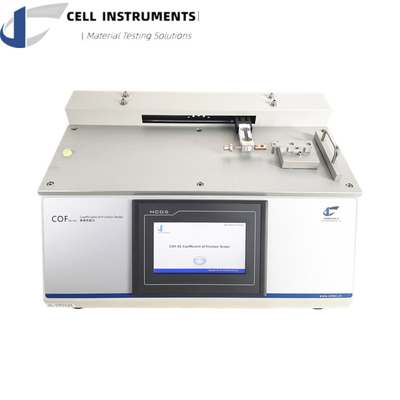

ISO 8295 Woven Bag Friction Coefficient Measuring Device Coefficient Of Friction Tester For Food Plastic Packaging Film

| Load Cell | 5 N(or As Required) | Accuracy | 0.5 F.S. |

|---|---|---|---|

| Sled | 200±1g (or As Required) | Sled Size | 63.5mm*63.5mm (or As Required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) | Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg | Power | 110~220V 50/60Hz |

ISO 8295 Woven Bag Friction Coefficient Measuring Device Coefficient Of Friction Tester For Food Plastic Packaging Film

![]()

Introduction to Woven Bag Friction Coefficient Measuring

The Woven Bag Friction Coefficient Measuring process is a critical evaluation in material testing. It determines how easily two surfaces slide against each other, which is essential in packaging, food, medical, and other industries. The coefficient of friction (COF) provides insights into the performance of materials, with lower values indicating ease of movement and higher values signaling a greater need for force. Woven Bag Friction Coefficient Measuring helps ensure that your materials are optimized for functionality and durability, which is why it is indispensable in packaging and product design processes.

Why Woven Bag Friction Coefficient Measuring Matters

The Woven Bag Friction Coefficient Measuring is pivotal for assessing the suitability of materials in various applications, from food packaging to medical devices. The frictional properties of materials such as woven bags impact their usability, handling, and efficiency. A variety of factors—such as the incorporation of antiblock agents, corona treatment, antistatic agents, and even the choice of inks and adhesives—can alter a material's coefficient of friction. Accurate Woven Bag Friction Coefficient Measuring can help to optimize these properties, ensuring smooth production processes and high-quality final products.

Application of the Woven Bag Friction Coefficient Measuring Device

The COF-01 Coefficient of Friction Tester is designed to measure the Woven Bag Friction Coefficient Measuring as well as the frictional properties of a wide range of materials. This versatile tester is crucial in ensuring the performance of packaging and other materials in various industries. Some of its key applications include:

- Plastic Films: The Woven Bag Friction Coefficient Measuring is essential for determining the slipperiness of plastic films, which is a key factor in packaging industries where smooth material handling is required.

- Textiles (Woven and Non-Woven Fabrics): This tester accurately measures the Woven Bag Friction Coefficient Measuring in fabrics, which is crucial for the textile industry, ensuring smooth production and handling.

- Paper and Paperboard: Packaging materials like paper require careful friction measurement to ensure they slide and stack efficiently during production.

- Rubber and Sheets: Woven Bag Friction Coefficient Measuring is used to assess the friction properties of rubber and sheets, which are common in manufacturing and automotive applications.

- Metal-Plastic Composite Belts: For applications like conveyor belts, accurate friction measurements ensure proper functionality, enhancing the performance of material handling systems.

Importance of Accurate Coefficient of Friction Measurements in Industry

In industries such as packaging, food, and pharmaceuticals, understanding the Woven Bag Friction Coefficient Measuring is crucial. Frictional characteristics can affect various stages of production, from material handling to the final product's performance. Improper friction characteristics may lead to issues like jamming, excessive wear, or difficulty in processing, especially in high-speed environments. Hence, Woven Bag Friction Coefficient Measuring ensures that materials behave predictably and efficiently during manufacturing, which is critical for quality control.

Technical Features of the COF-01 Coefficient of Friction Tester

- PLC Control & HMI Touch Screen: The COF-01 offers precise control through a PLC system and a user-friendly touch screen interface, allowing seamless operation and accurate measurements.

- Precision Mechanism: This device utilizes a stepper motor and precision ball lead screw, ensuring accurate and reliable testing of Woven Bag Friction Coefficient Measuring.

- Real-Time Data Display: Test results, including maximum, minimum, and average values, are displayed in real-time, which enhances the ease of monitoring during testing.

- Versatility: Capable of measuring both static and kinetic coefficients of friction, the COF-01 provides comprehensive testing capabilities for various materials.

Key Features of the Woven Bag Friction Coefficient Measuring Tester:

- Testing Range: Accurate measurement of static and kinetic friction for a wide variety of materials.

- Customization: Configurations like sled size, test speed, and load cell capacity can be customized to suit specific requirements.

- High Precision: Designed to provide reliable and repeatable results with an accuracy of 0.5 F.S.

- Standards Compliance: Adheres to recognized standards such as ISO 8295, ASTM D1894, and TAPPI T816, ensuring consistent and globally accepted results.

Main Parameters:

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Ensuring Accurate Woven Bag Friction Coefficient Measurements

By incorporating the Woven Bag Friction Coefficient Measuring device into your quality control processes, you can ensure that your materials meet the necessary standards and perform optimally under real-world conditions. Whether you’re in the packaging, food, or pharmaceutical industries, having precise data on frictional properties can significantly improve your product quality and manufacturing efficiency. This instrument is a valuable addition to any laboratory focused on material testing.

Standards and Compliance

The Woven Bag Friction Coefficient Measuring tester is designed in accordance with key international standards, ensuring that it provides reliable and reproducible results. Some of the key standards include:

- ASTM D1894: This standard provides guidelines for measuring the coefficient of friction of plastic films and other materials.

- ISO 8295: Provides a global benchmark for testing the friction properties of plastics and films.

- TAPPI T816: A standard for testing the coefficient of friction of paper and paperboard materials.

- GB 10006: A Chinese national standard for measuring the frictional properties of packaging materials.

Contact Us for Woven Bag Friction Coefficient Measuring Solutions

If you are looking for precise and reliable Woven Bag Friction Coefficient Measuring solutions, the COF-01 Coefficient of Friction Tester is your go-to device. Contact us today to discuss your testing needs or get more information on how our tester can help improve your material testing processes. We are committed to providing you with the best in industry standards, reliability, and customer support.

![]()