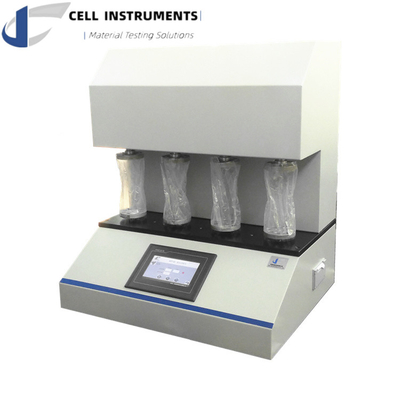

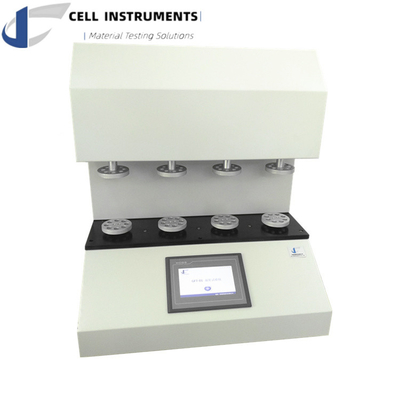

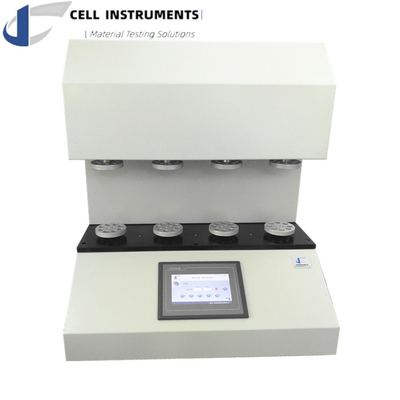

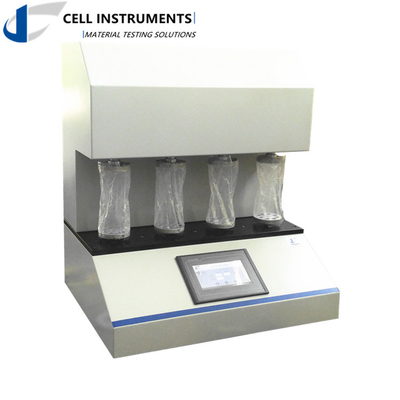

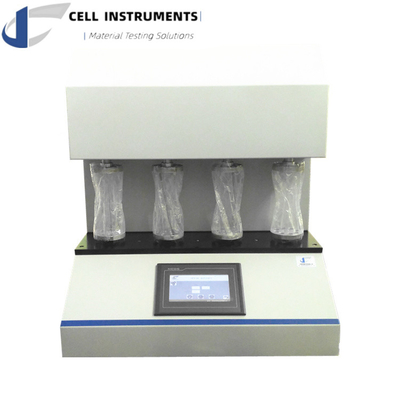

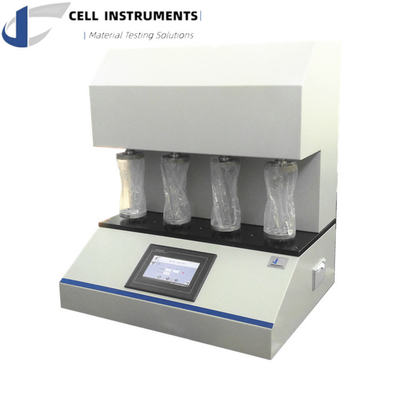

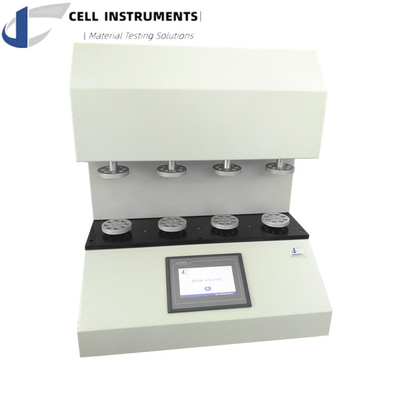

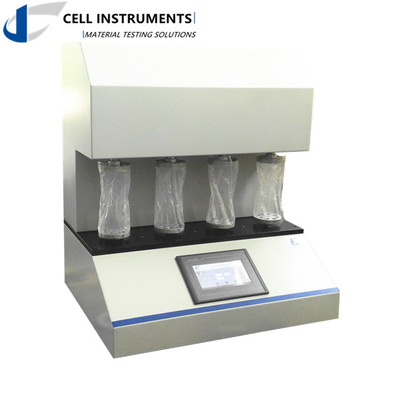

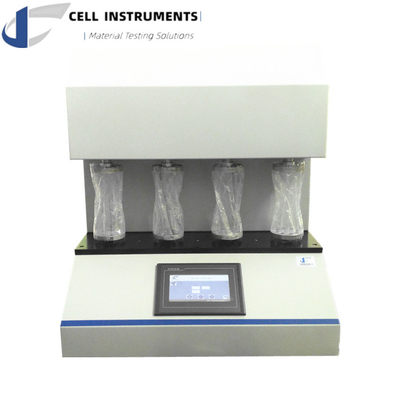

ASTM F392 Economical Multi-Station Flexing Sample Preparation Instrument Efficient Barrier Film Flex Durability Tester

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 2.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 4 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

ASTM F392 Economical Multi-Station Flexing Sample Preparation Instrument Efficient Barrier Film Flex Durability Tester

![]()

Introduction to Flexing Sample Preparation Instrument

The GFT-01 Flexing Sample Preparation Instrument by Cell Instruments is a state-of-the-art device designed to evaluate the flex durability, also known as Gelboflex resistance, of flexible barrier materials. This key property determines how well materials such as films, composites, and coatings can withstand repetitive flexing, making it essential for industries that rely on high-performance packaging. The Flexing Sample Preparation Instrument plays a crucial role in determining the resilience of materials to flex cracking, pinhole formation, and other forms of structural damage that can compromise packaging integrity.

Designed for diverse applications, the GFT-01 Flexing Sample Preparation Instrument ensures that packaging materials meet the necessary quality standards before they enter production and distribution cycles. From plastics and textiles to food, pharmaceuticals, and printing industries, this instrument guarantees consistent and repeatable measurements, helping manufacturers protect their products and maintain quality during transit.

Advantages of Using the Flexing Sample Preparation Instrument

-

Accurate Flex Durability Measurements: The Flexing Sample Preparation Instrument accurately measures a material's ability to resist flex cracking by simulating repetitive strain, providing invaluable data on the material's durability.

-

Enhanced Package Integrity: The resistance against flex cracking evaluated by the Flexing Sample Preparation Instrument ensures that packaging remains intact throughout distribution, protecting the contents from damage. This is especially important for industries where the physical integrity of packages is vital for product quality.

-

Versatile Testing Applications: Capable of testing a wide range of materials including films, composites, and coating films, this Flexing Sample Preparation Instrument serves various industries, including packaging, textiles, food, pharmaceuticals, and more.

-

Compliance with Industry Standards: The Flexing Sample Preparation Instrument complies with ASTM F392, ensuring that your flex durability tests meet globally recognized benchmarks for material testing.

Why You Need the Flexing Sample Preparation Instrument

The GFT-01 Flexing Sample Preparation Instrument is an indispensable tool for industries working with flexible barrier materials. Here’s why it’s a critical part of your quality control process:

-

Quality Assurance: Ensures materials meet required flex durability standards, preventing potential failures during the distribution cycle.

-

Preserving Product Integrity: By evaluating the flex durability of materials, the Flexing Sample Preparation Instrument helps maintain the structural integrity of packaging, which is critical for industries like food and pharmaceuticals where package failure could lead to contamination or spoilage.

-

Regulatory Compliance: The Flexing Sample Preparation Instrument is compliant with ASTM F392, providing results that adhere to industry standards and regulatory guidelines. This helps businesses maintain consistency and pass certification audits.

What Does the Flexing Sample Preparation Instrument Do?

The GFT-01 Flexing Sample Preparation Instrument simulates repetitive flexing conditions to evaluate how well materials can endure stress over time. It subjects the sample material to twisting and horizontal compression, mimicking the conditions it would face during packaging and distribution. The tester assesses the resistance of materials to pinhole formation and flex failure, which ultimately helps determine whether the material can maintain package integrity under real-world conditions.

Applications of the Flexing Sample Preparation Instrument

The Flexing Sample Preparation Instrument is widely used across various industries to test materials used in packaging, coatings, and composites. Some key applications include:

-

Plastics Industry: Ensuring the flexibility and durability of plastic films and packaging materials.

-

Food & Pharmaceutical Packaging: Evaluating the resistance of barrier films in food and pharmaceutical packaging to ensure safety and integrity during transportation.

-

Textile Industry: Testing flex durability for textile materials used in packaging applications.

-

Printing and Adhesives: Verifying the strength and durability of films and coatings used in printing and adhesive processes.

Technical Features of the Flexing Sample Preparation Instrument

The GFT-01 Flexing Sample Preparation Instrument is equipped with advanced features to enhance testing efficiency:

-

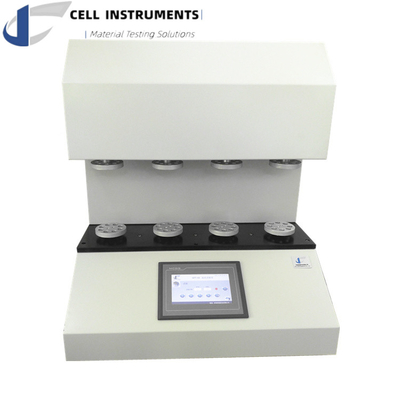

PLC Control System: Ensures precise control over the flexing process for accurate and repeatable results.

-

HMI Touchscreen Interface: Allows easy operation and access to testing data, simplifying the user experience.

-

Microprinter: Provides convenient printouts of test results, enabling quick and efficient documentation.

-

Flexible Stroke Modes: The instrument offers switchable stroke modes, giving users flexibility to choose between long and short stroke options.

-

Multiple Test Modes: Includes five pre-set test modes (A, B, C, D, and E) to accommodate various testing conditions.

Main Parameters of the Flexing Sample Preparation Instrument

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

Compliance with Standards

The GFT-01 Flexing Sample Preparation Instrument adheres to ASTM F392, the standard for testing the flex durability of flexible barrier materials. This ensures that your testing process aligns with globally recognized industry practices, providing reliable and trustworthy results.

Why Choose the GFT-01 Flexing Sample Preparation Instrument?

The GFT-01 Flexing Sample Preparation Instrument from Cell Instruments is designed to meet the rigorous testing needs of industries that rely on flexible barrier materials. With its advanced technology, precise measurements, and compliance with international standards, this instrument ensures that your packaging materials are durable and resilient enough to withstand the stresses of the distribution cycle.

![]()