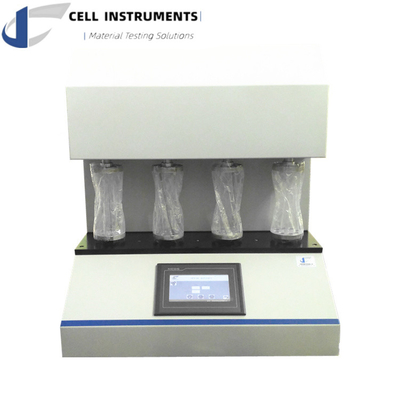

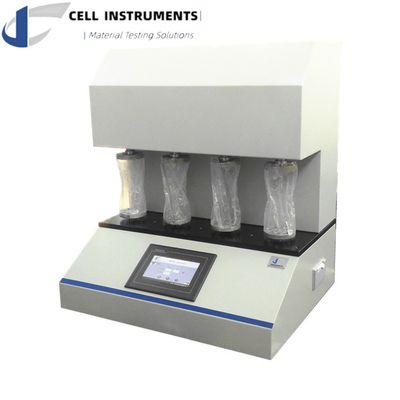

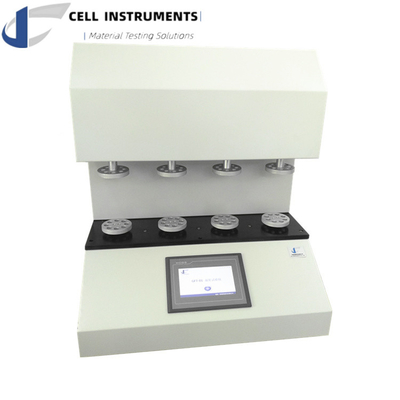

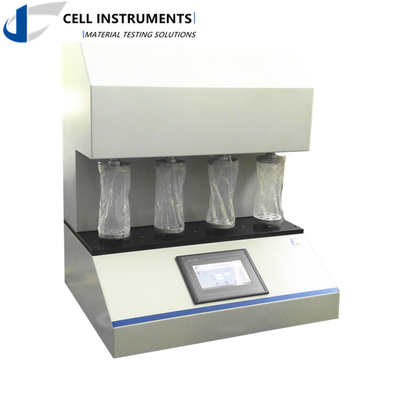

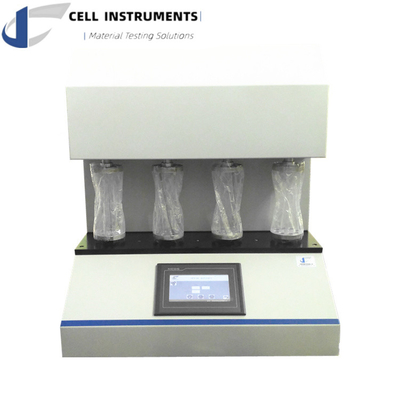

ASTM F392 Barrier Film Quality Lab Testing Machine Flex Durability Testing Instruments Barrier Film Sample Preparation

| Flex Frequency | 45 /minute | Flex Angle | 440° (90 Mm) Or 400° (80 Mm) |

|---|---|---|---|

| Capacity | 2.5 N.m | Horizontal Stroke | 155 Mm Or 80 Mm |

| Stations | 4 | Sample Size | 280 Mm X 200 Mm |

| Power | 110~220V |

ASTM F392 Barrier Film Quality Lab Testing Machine Flex Durability Testing Instruments Barrier Film Sample Preparation

![]()

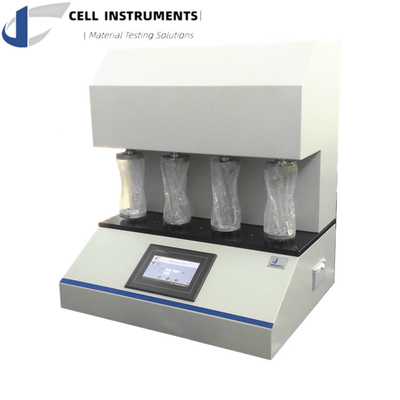

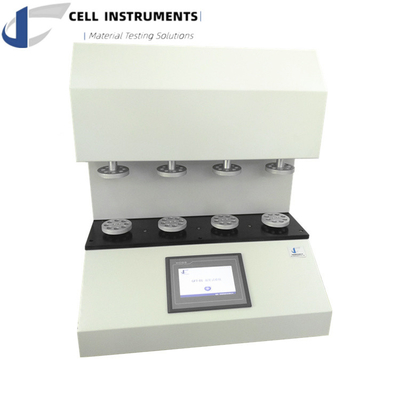

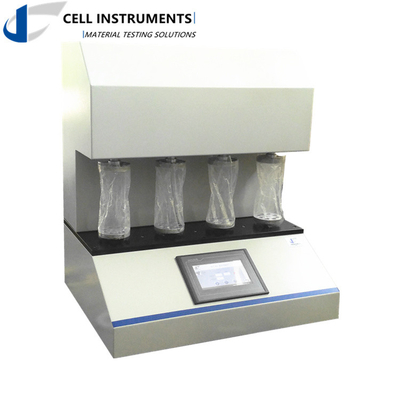

The Flex Durability Testing Instrument, known as the GFT-01 Flex Durability Tester, is a state-of-the-art device designed to evaluate the flex durability or Gelboflex resistance of flexible barrier materials. This testing instrument is essential for assessing the ability of materials such as films, composites, and coatings to endure repetitive strain and resist flex cracking. Flex durability is a critical property for materials used in packaging applications, where maintaining the structural integrity of flexible barrier films is essential to prevent product damage during distribution.

Key Features of the Flex Durability Testing Instrument (GFT-01)

The Flex Durability Testing Instrument is a versatile, high-precision device that performs critical tests on materials subjected to repetitive strain. Here are the standout features of the GFT-01 model:

-

Precise Flex Durability Measurement: The GFT-01 Flex Durability Tester accurately measures the material's resistance to flex cracking. The instrument detects pinholes in the sample structure, which are indicators of potential package failure.

-

Preservation of Package Integrity: The tester plays a vital role in evaluating the strength of barrier films, ensuring they can withstand the rigors of distribution and remain intact, preserving the contents within.

-

Versatility in Applications: This instrument is suitable for testing a wide range of materials, including films, composites, and coating films. It provides flexibility for industries such as plastics, textiles, food, pharmaceuticals, printing, and adhesives.

Why You Need the Flex Durability Testing Instrument

The Flex Durability Testing Instrument is a necessary tool for quality control and assurance in industries dealing with flexible barrier materials. It ensures that materials can endure stress without failure, contributing to the longevity and reliability of the packaging.

-

Quality Assurance: The GFT-01 ensures materials meet required flex crack resistance standards, preventing the development of holes or breaches in packaging during the distribution process.

-

Maintaining Package Integrity: The GFT-01 tester evaluates how materials react under repetitive strain, which is crucial for maintaining the packaging's integrity throughout its lifecycle.

-

Compliance with Industry Standards: The GFT-01 tester helps companies comply with important industry standards, such as ASTM F392, by providing accurate, repeatable flex durability test results.

The Purpose of the Flex Durability Testing Instrument

The GFT-01 Flex Durability Tester simulates repetitive strain by subjecting materials to a combination of twisting and horizontal compression. This mimics the real-world conditions materials undergo during shipping, handling, and storage. The main purpose of this testing instrument is to assess the flex durability or Gelboflex resistance of flexible barrier materials, ensuring they can withstand the stress of distribution without developing pinholes or cracks that compromise package integrity.

Applications of the Flex Durability Testing Instrument

The Flex Durability Testing Instrument is widely used across various industries to assess the quality and durability of barrier films and other flexible materials. Key applications include:

- Plastics Industry: Ensuring the durability of flexible plastic films used in packaging.

- Food and Pharmaceutical Packaging: Protecting the integrity of food and pharmaceutical product packaging, preventing contamination or spoilage.

- Textile Industry: Testing the flex durability of textiles used for packaging purposes.

- Printing and Adhesives Industry: Verifying the quality of films and coatings used in the printing and adhesives sectors.

Standards Compliance

The GFT-01 Flex Durability Testing Instrument is designed to comply with industry standards such as ASTM F392, which outlines the testing requirements for flexible barrier materials. By adhering to these established benchmarks, the GFT-01 ensures that results are consistent and reliable, making it an essential tool for maintaining industry standards.

Main Technical Parameters

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

Advanced Features

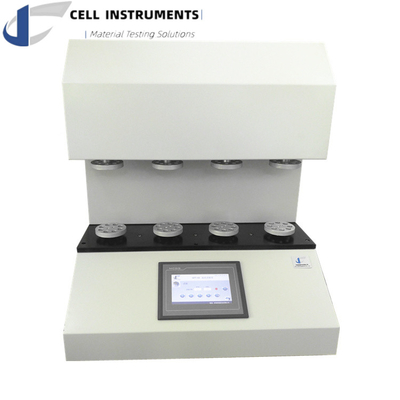

The Flex Durability Testing Instrument is equipped with several advanced features to enhance user convenience and testing efficiency:

-

PLC Control: The system uses PLC (Programmable Logic Controller) for precise and reliable control of the testing process.

-

HMI Touch Screen Interface: The intuitive touch screen interface makes it easy for users to set up, monitor, and analyze tests.

-

Microprinter: A microprinter for easy output of test results, allowing for quick record-keeping and analysis.

-

Switchable Stroke Modes: Users can easily switch between long and short stroke modes, increasing flexibility in testing different materials.

-

Multiple Test Modes: Five standard test modes (A, B, C, D, and E) offer flexibility in configuring tests based on material properties and testing requirements.

Why Choose the GFT-01 Flex Durability Testing Instrument?

The GFT-01 Flex Durability Testing Instrument is designed for industries where flexible barrier materials play a critical role in maintaining product integrity. With its precise measurement capabilities, advanced features, and compliance with ASTM standards, the GFT-01 is an indispensable tool for ensuring that packaging materials meet the required durability standards.

The GFT-01 Flex Durability Testing Instrument is more than just a testing device; it is a comprehensive solution for quality assurance and material analysis. Its ability to simulate real-world conditions makes it an invaluable asset for companies that prioritize packaging integrity and material performance.

![]()